After 3D printing over 20 million parts for over one million customers, it’s safe to say that Shapeways has seen a lot when it comes to additive manufacturing. Shapeways designers keep the innovations rolling in daily, motivating us to continually expand the lineup of advanced technology and materials for custom 3D printing services.

Research analysts project continued acceleration of the 3D printing market, valued at USD 13.84 billion in 2021 and now expected to grow at a compound annual growth rate (CAGR) of 20.8% from 2022 to 2030. This includes additive manufacturing in a wide range of industrial applications.

3D Printing Aerospace/Drone Technology

3D printing for aerospace technology is especially popular with drone manufacturers because of the ability to customize and lightweight extremely strong parts, whether using materials like Nylon 12 [Versatile Plastic] or metals like Aluminum.

3D printing in aerospace is projected to reach USD 5.58 billion by 2026 at 25.7% CAGR. Drone technology commands about a third of the aerospace market for 3D printing with the ability to create rapid prototypes, high-performing functional parts, and replacement parts which can be made exponentially faster. Shapeways customers like Quantum-Systems exemplify the efficacy of 3D printed drones, especially in demonstrating that medical test samples can be flown to labs in a fraction of the time when compared to other courier services.

Relying on materials like Nylon 12 [Versatile Plastic] and MJF Plastic PA12, Quantum-Systems has been working with Shapeways to 3D print drone parts since they founded their company in 2015. This additive manufacturing partnership allows Quantum-Systems to reduce design and production cycles for all their drones, from the initial design phase and rapid iteration of prototypes to preparing fully vetted parts that become functional end-use prototypes. There is a huge impact on the bottom line too as they save tens of thousands of dollars in pre-production and testing costs.

Other long-time Shapeways customers like Kespry are 3D printing drone parts for aerial intelligence related to tasks in establishing risk assessment, assisting insurance agents in closing claims, overseeing earthwork operations in large-scale construction projects and collecting site data, and surveying large factory operations like pulp and paper mills. Their initial goal in 3D printing with Shapeways was to ensure repeatability and accuracy so parts could be manufactured on-demand.

Beginning with drone covers to protect the mechanical inner workings of their UAVs, Kespry realized they could 3D print parts more economically with Nylon 12 [Versatile Plastic] or MJF PA12 in comparison to Injection Molding–as well as prototyping more efficiently and getting products to market faster.

Other applications for 3D printed drones include:

- Military use

- Security and monitoring

- Management of crops, wildlife, and livestock

- Consumer delivery

- Aerial photography

- Machine inspections, including wind turbines

A multitude of enthusiasts in the Shapeways Marketplace design and 3D print drones for both the industrial and hobby sectors, offering a wide range of options for drone 3D printing materials, technology, and colors and finishes.

3D Printing for Architecture

Allowing architects to shed labor-intensive processes and a challenging hodgepodge of materials like paper and cardboard, 3D printing makes it possible to create realistic models for client presentations, product development, and permanent displays. With 3D printing materials like High Definition Full Color, architects can even build an entire city block in miniature, replete with vibrant visualizations and infrastructure like traffic areas and landscaping.

Shapeways customers like Tapperworks enjoy using a range of 3D printing materials. This was demonstrated in their full color 3D printed architectural model of The Village, made with a combination of Fine Detail Plastic, High Definition Full Color, and Sandstone. At a scale of 1:100, Tapperworks’ goal was to make the permanent 3D printed display large enough for viewers to walk all the way around, featuring 5 towers and 94 apartments.

With 3D printing architecture serving the construction industry directly, the potential for growth continues to accelerate, and analysts are projecting a CAGR of 100.7% from 2022 to 2030. While working on a luxury remodeling project in California, designers from Verner Architects partnered with Shapeways to 3D print a six-foot bathroom vanity using Nylon 12 [Versatile Plastic]. Inspired by the client’s idea for a conceptual design based on coral reefs, Verner Architects realized they needed a 3D printing material that could be waterproofed–and one strong enough to hold up to the test of time.

The Verner Architects 3D printed vanity represents a growing trend of designers and engineers turning to 3D printing for larger-scale items–made possible with the larger printbed size in Selective Laser Sintering (SLS).

3D Printing for Medical

Projected by analysts to reach $5,846.74 million by 2030, 3D printing for healthcare applications is expected to grow at a CAGR of 20.10% from 2021 to 2030. Offering tremendous impacts globally, 3D printing for medical applications often begins with the 3D printed model, made possible after medical imaging is converted into a 3D file.

Shapeways has been privileged to work on some extraordinary projects with companies around the world, and Uruguay-headquartered Armor Bionics is no exception. Armor Bionics provides detailed, accurate models–described as the GPS for surgeons–helping them shorten time in operating rooms, reduce recovery times for patients, and decrease the margin for effort by providing more precise diagnostic and training tools.

The 3D modeling process begins as Armor Bionics explains what they need from the customer, beginning with images that can be sent to them online. The Armor Bionics team designs the model according to all specifics outlined by the customer, often complex.

Once the model has been cleared and is ready for production, it is sent to Shapeways for 3D printing in Nylon 12 [Versatile Plastic]. From there, a surgeon can:

- Diagnose the patient

- Outline a treatment plan

- Prepare and train for surgery, relying on the 3D printed medical model

- Use the 3D printed medical model as a visual aid for educating patients and families

- Train medical students

Other designers like Flamingo Works have turned their talents toward 3D printing complex–and highly effective–surgical training platforms. Upon a client request of their own, the Flamingo Works industrial design team created a learning system for robot-assisted surgeries. Doing away with convention, they created a gamified system that is colorful and fun, making use of the many options for colors and finishes available with Nylon 12 [Versatile Plastic] and Selective Laser Sintering. This 3D printing material/technology combination fulfilled project requirements for durability due to long-term use of the training tools.

Flamingo Works took advantage of the rapid prototyping process, developing 50 to 60 learning tasks at a time and sending them to physicians for assessment. With the ability to iterate as needed, they could develop one skill and remove another while prototyping.

Taking another angle in 3D printing for healthcare, Voytek Medical 3D prints colorful organizers and clasps for hospital equipment. Spurred on to increase efficiency as seeing so much medical equipment continually out of commission due to missing cables, Steven Jarworkski, CEO of Voytek, was inspired to design sturdy devices for clamping cords into place. Partnering with Shapeways, he was able to scale his growing business as needed, 3D printing a variety of options for medical facilities and in different colors for delineating between machines and departments.

Luxury 3D Printed Jewelry

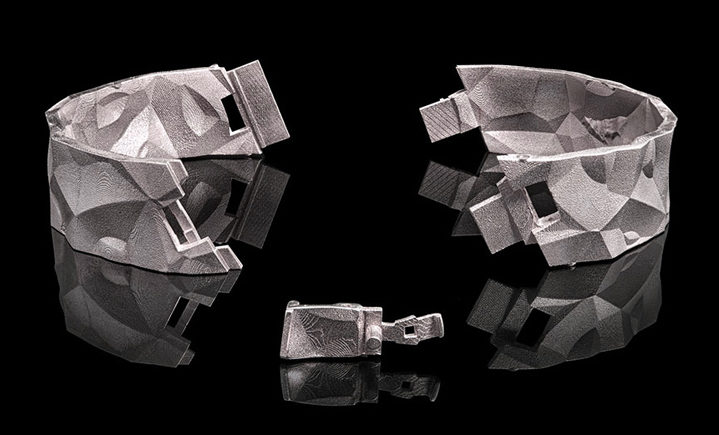

Shapeways has so much to offer when it comes to 3D printed jewelry, whether customers are shopping at our Marketplace or designing for their own businesses. Long-time customers Groen & Boothman have been experimenting with 3D design, materials, and technology for years. We’ve highlighted two of their most recent projects as they exemplify effective use of the prototyping and production process–resulting in two different series of luxury bracelets.

For their Creatures 3D printed bracelet series, Groen & Boothman prototyped extensively with Nylon 12 [Versatile Plastic] and used it for the final product. Their 3D printed cuff bracelets are lightweight at about .7 ounces each, but strong and durable. Ultimately, the designers endeavor to make luxurious, high-quality pieces that encourage continued value over the long-term in comparison to buying cheaper, mass-produced pieces that are often disposable.

For their Elements series, Groen & Boothman turned to Shapeways for their expertise in Wax Casting. The designers chose Sterling Silver to create two different styles in the series: Water and Cosmic. The bracelets, polished by hand, also feature a clever hidden clasp mechanism and hinge.

Tool Making

Shapeways provides custom 3D printing services and traditional manufacturing. What many people are not aware of, is that 3D printing is responsible for making a variety of molds that can be used in traditional manufacturing like Injection Molding. 3D printed molds can be made out of materials like Nylon 12 [Versatile Plastic], MJF PA12, Sandstone, and Thermoplastic Polyurethane (TPU). Molds can also be 3D printed in Steel or Stainless Steel.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.