Create (with) vision and (with) joy – Jeroen Tapper

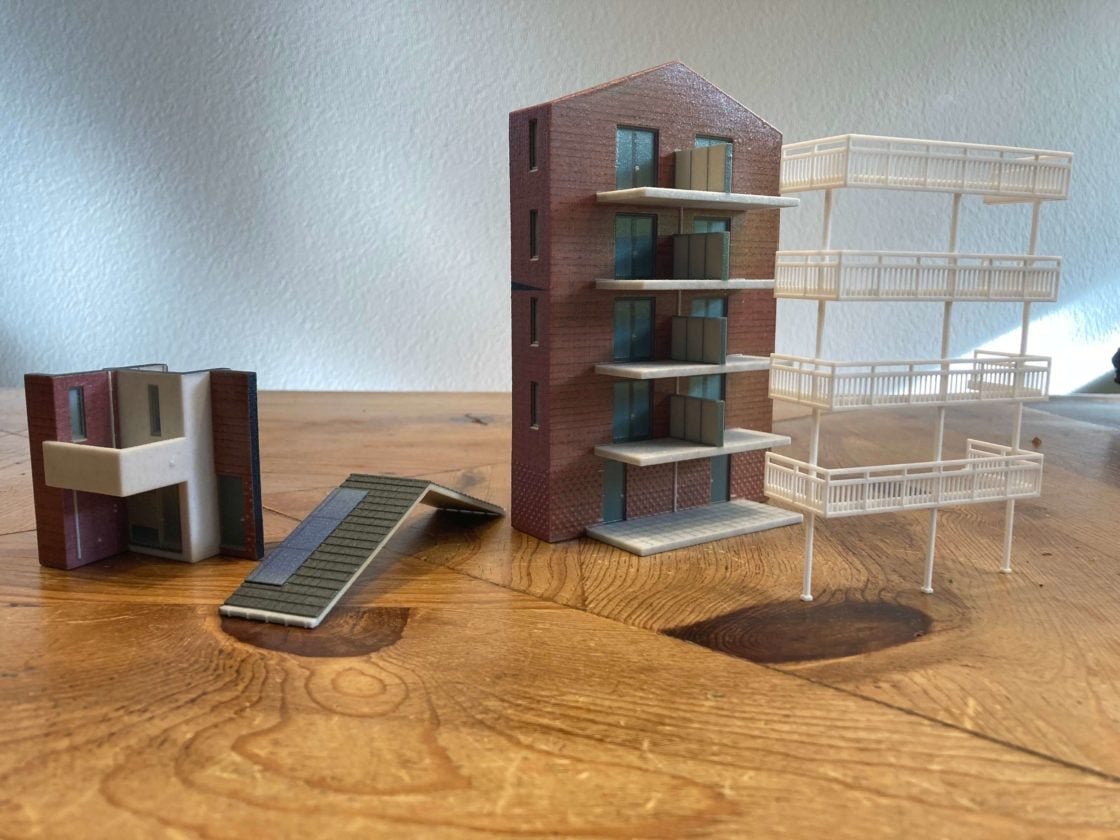

3D printing offers substantial contributions to many critical industrial applications and represents an ongoing evolution for designers on every level. Tapperworks, an architectural visualization firm founded by Jeroen Tapper, offers a great example in the Netherlands with the completion of the company’s most challenging project yet. The Village is a 3D printed architectural scale model featuring 94 apartments and five towers, making it clear that Tapper is serious about expanding his firm’s work.

With 3D printing architecture serving in direct relation to the construction industry, growth is tremendous; in fact, analysts have recently projected a compound annual growth rate (CAGR) of 100.7% from 2022 to 2030. Most projects emerge from modeling software, with market growth driven by 3D printing in both rapid prototyping and manufacturing of end-use products–as well as increasing popularity and global adoption of ‘green projects.’

3D Printed Architecture Allows Viewers to Explore Every Angle

The Village allows viewers to see every feature of the apartment complex as they walk around the 3D printed architecture. Serving as a representation of the already existing complex, The Village pays homage to the detailed construction on a miniature level. The architectural visualization transformed into a 3D printed model is also a testament to the massive growth of Tapperworks as a firm, and Jeroen Tapper as a lifelong artist.

The architectural visualizer remarks that he is indeed in his element when designing and 3D printing for Tapperworks:

“I work with clients who fit me very well, making it clear what they need but allowing me a lot of freedom in my work.”

A designer who believes in sharing knowledge, Tapper has also learned immensely from industry peers.. Ongoing collaborations in architectural visualization and 3D printed architecture have inspired him to take on new perspectives and skills for enhancing operations at the Tapperworks studio over time. As he began working on larger projects for Tapperworks, the designer reached back out to Shapeways for assistance, allowing him to deliver expansive, colorful 3D printed models like The Village.

Overcoming Accuracy Challenges in 3D Printed Architecture

After taking on large projects in 3D printing architecture like The Village, Tapper realized how valuable it is to listen to his clients and embrace what they are looking for. That usually boils down to less of a vibe or a concept and focuses on realism in architecture–and ultimately, real-estate sales. Completing The Village was no easy feat; in fact, Tapper said that at times he thought it might be altogether ‘undoable.’ Different parts of the architectural visualization required other 3D materials and technology, and to achieve perfection, completing the model also meant affixing some parts together with glue.

Adding to growth in his work and knowledge, the designer took time to learn about and experiment with 3D printing materials like Fine Detail Plastic, High Definition Full Color, Sandstone, and their accompanying technologies. Tapper gives tremendous credit to the patience of his client who allowed him time to construct and manufacture the 3D printed architectural model, as well as to the Shapeways team who assisted in streamlining production.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.