The 3D printed medical device market is projected to double from 2018-2022 at a compound annual growth rate (CAGR) of 17.5%. This leap is due to a number of factors including technological advancements, increased funding, possibilities for mass customization and growing applications in the healthcare industry.

The demand for patient-specific devices has risen and 3D printing, or additive manufacturing – the term most often adopted when referring to industrial usage including end-use part production – facilitates meeting that need. Since the spread of COVID, we have also seen its ability to meet urgent needs where traditional supply chains were unable to. 3D printing has shown that it is tremendously cost and time effective and is a highly flexible technology. Its growth is measured according to four categories: 3D printing technologies, components, products and global regions. Here is a look at each of these categories:

3D Printing Technologies

3D Printing technologies are classified by processes such as binder jetting, extrusion, 3D bioprinting, and photopolymerization (SLA, DLP).

Photopolymerization

Photopolymerization is used for the production of many different medical devices such as catheters, surgical guides, prosthetics and implants, etc. The use of this technology is expected to increase because of its environmental compliance and its ability to produce devices at a low temperature due to UV curing. It is a technology that produces parts with intricate details and smooth finishes and is consistently evolving to suit growing needs.

Powder Bed Fusion

Powder bed fusion is another popular technology used for the printing of medical devices because it uses similar materials like nylon and titanium and produces highly solid, complex parts.

Bioprinting

In 3D bioprinting, materials known as “bio inks” can be used to create tissue-like structures that can then be grown to help replace defective tissue or organs. 3D bioprinting allows for highly precise scaffolds to direct the growth of the tissue as accurately as possible. Tissue can grow in a bioreactor chamber that can also be 3D printed. 3D printing technologies present a wide range of applications in the healthcare industry that continue to develop and grow.

3D Printing Components

3D Printing components are segmented into software & services, equipment and materials.

Software & Services

Softwares & services comprise the platforms that facilitate the innovation, design and production of 3D printed medical devices. Advances in computer-aided design (CAD) and computer-aided manufacturing (CAM) have improved medical product designs to fit the needs of this industry. Improved printing of porous structures, for example, have allowed printed implants to better take on the characteristics of bones.

3D Printing Equipment

Equipment refers to the printers being used, whether they be 3D printers used for printing instruments or implants, or 3d bioprinters, used for tissue engineering. More and more facilities are equipping themselves with 3D printers to help provide themselves with tools on demand, and other companies use services like Shapeways to meet their printing needs.

Materials

Materials account for plastics, metals and alloys, biomaterials, and anything else that facilitates the production of medical devices that are compatible with regulations. Biocompatible metals and alloys are the most used materials because they are more suited to avoid complications, but the use of biomaterials is expected to surge. Being able to print with materials like silicone that mimic tissue properties are perfect for training physicians or for practicing, as they are cheaper than cadaver parts.

3D Printed Products

3D printed medical devices largely consist of surgical guides, surgical instruments, prosthetics, implants and scaffolds.

Products for Physicians – Surgical Instruments & Guides

3D printed surgical tools and guides, devices used by doctors, surgeons and dentists, can be 3D printed as needed with individual specifications. Surgical guides are expected to account for the largest share of growth in the forecast period. Using 3D scanning technology, surgeons can improve their surgical planning by printing patient-specific anatomical models to practice, to create better implant fits or simply provide more visual information. This reduces surgery time which can also reduce the possibility of infection. With 3D printing not only can instruments be printed on demand, but the function of surgical tools can be improved by optimizing the design to suit specific surgeons or patients.

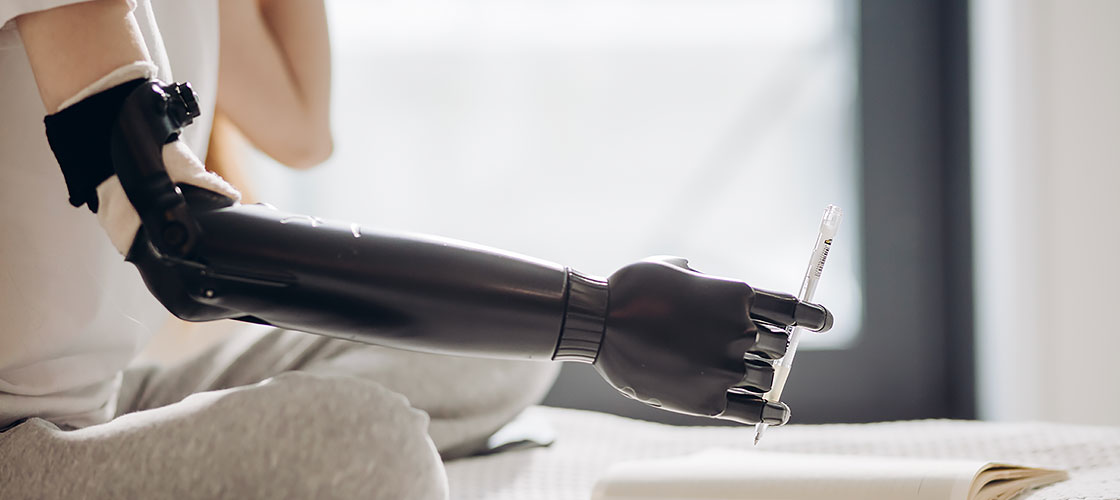

Products for Patients – Implants and Prosthetics

Medical devices that are used by patients, like implants and prosthetics benefit largely from the customization enabled by 3D printing. Pieces can be fit to the exact anatomical specifications of each patient and be printed affordably and quickly, where traditional manufacturing would require multiple casting processes at tremendous costs. Prosthetics company Mitt Wearables, for example, uses 3D printing to create more affordable, lightweight models that are customizable with different hand attachments. The cost efficiency paired with the customization abilities of 3D printing make it a crucial tool for made-to-order medical devices that will continue to progress technologically, sharpening the skills of physicians and the care of patients.

Growth by Region

The global market is divided into the following sections: North America, Europe, Asia Pacific, Latin America and Middle East & Africa. Each region is set to grow due to a worldwide increased awareness as well as an increase in advances and funding for 3D printing technology as well as the demand for patient-specific products.

North America

North America makes up the largest share of the 3D printing medical device market and hosts some of the most innovative companies that contribute to the healthcare industry. It also has more funding allotted to research and development to propel innovations forward. Thanks to collaborations between 3D printing and healthcare companies, more and more hospitals are implementing 3D technology into their facilities.

Europe

Europe is also actively developing 3D printing technology thanks to government funding and being the home to key industry leaders guiding the implementation of additive manufacturing for end parts in healthcare.

Asia Pacific

Asia Pacific is quickly catching up, putting more emphasis on 3D printing with increased research and training. The Chinese government has heavily invested in the 3D printing industry, forwarding the development of personalized, biocompatible implants while reducing materials. Facilities for industrial additive manufacturing have been increasing in Singapore, Taiwan and India as well.

Middle East

The United Arab Emirates aims to become a global 3D printing hub by 2030 and have begun implementing 3D technology in dentistry by scanning and printing models of teeth to make prosthesis.

Because traditional manufacturing can be expensive and time consuming, many companies are turning their focus to 3D printing to develop new and improved ways of satisfying medical needs. Customization, material choices and the ability to print complex shapes and designs make 3D printing a crucial tool in innovating medical devices all over the world. While there are strict regulations in place for medical devices that can occasionally slow production processes, the increases in funding and technological advancements for 3D printing propel its growth substantially and will likely continue to do so.

We at Shapeways have helped companies such as Mitt Wearables manufacture customized medical devices. Let us know how we can help with your medical 3D printing needs.