Our customers are proving every day that parts produced with additive manufacturing can meet stringent production standards across aerospace, medical, robotics and consumer goods sectors.

The measurable outcomes they see including faster cycles, lower costs, reduced risk and verified quality are the real drivers, not the technology itself. And these are not speculative benefits but are documented results drawn from thousands of manufacturing runs, design iterations and field-tested components.

Here we will share some anonymised case studies exploring how our digital manufacturing platform translates design freedom into production-grade results.

Aerospace: From prototype to flight in weeks

One aerospace manufacturer developing electric aircraft needed to design lightweight structures that could withstand aerodynamic loads while remaining serviceable in harsh outdoor conditions. Traditional tooling would have meant six-figure investment and months of delay.

By shifting to additive manufacturing production for structural and non-critical components, the engineering team reduced design-to-flight time by more than 40%. Each aircraft now integrates between 60 and 80 additively manufactured components, including housings, brackets, interface panels and sensor mounts all produced using laser-sintered nylon and MJF PA12.

Over hundreds of flight hours, none of these printed parts have shown degradation within design loads. The company’s lead engineer put it plainly: 3D printing has become “as routine as machining, but faster, lighter and easier to validate.”

For aerospace projects where certification and reliability rule every decision, that shift marks a genuine transformation: iterative engineering without compromise.

Healthcare: Scaling innovation, protecting assets

In hospital environments, reliability is life-critical. A medical-equipment supplier faced recurring failures in cable management systems that caused downtime, safety issues and cost leakage. They worked with Shapeways to design a simple but robust 3D printed retention device — small enough to overlook, but powerful enough to prevent six-figure losses annually.

Within months, the supplier had deployed over a thousand units, each digitally manufactured on demand from validated, biocompatible materials. The result: a projected $1 million in equipment assets protected and near-zero replacement delays.

Elsewhere in the medical field, a design team creating robotic-surgery training systems used additive manufacturing to reinvent the way surgeons learn delicate procedures. Their challenge was to simulate complex, dexterous motions without relying on expensive cadaver or synthetic models.

Using selective laser sintering (SLS), the team created hundreds of modular parts, colour-coded and nested for efficient builds, and tested through rapid iteration. The outcome was a fully modular training platform that could be reconfigured for multiple skill levels and shipped globally without tooling. The designers estimate that Shapeways’ rapid-prototyping capability cut their development time by more than half — and opened new possibilities for data-driven medical education.

Hardware & Robotics: Manufacturing at the speed of innovation

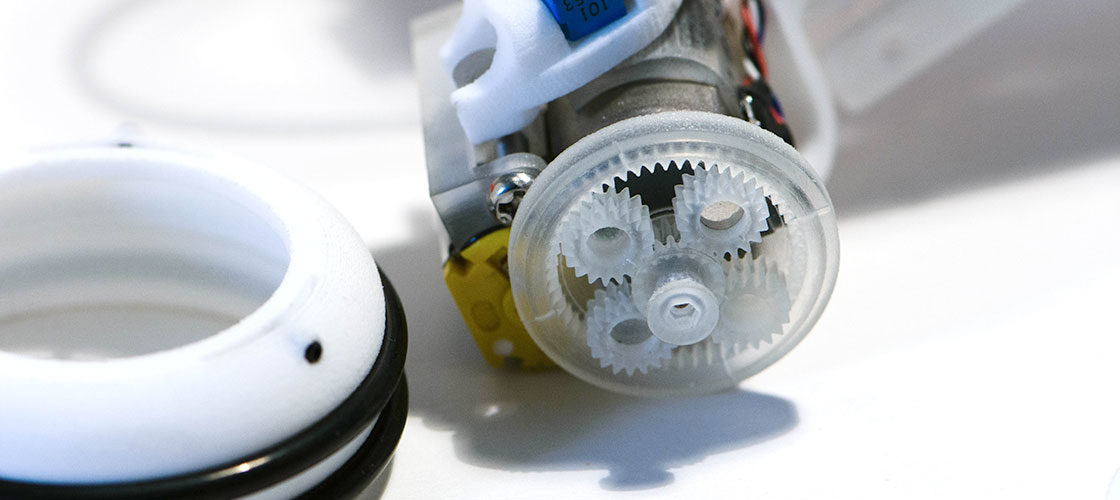

In high-tech hardware development, time is the enemy of innovation. A robotics startup specialising in micro-manufacturing systems needed to overhaul a precision pick-and-place mechanism that wasn’t performing reliably. Early attempts at in-house additive manufacturing production lacked precision and mechanical strength; injection moulding was cost-prohibitive.

Shapeways produced the redesigned component in PA12, delivering superior rigidity and consistent tolerances. The part handled twice the payload of the original version, and the team moved from prototype to production in days instead of weeks.

That single improvement cascaded through the company’s development cycle, enabling faster iteration and higher-quality end products. The same partner moved on to source nearly all production components through Shapeways’ qualified manufacturing network, citing repeatability, dimensional accuracy and speed of delivery as decisive factors.

Consumer & Design: Scaling bespoke manufacturing

Designers and consumer brands are equally demanding in aesthetics, precision and consistency. One luxury-goods studio uses Shapeways’ metal and polymer printing to create algorithmically generated jewellery pieces that are each unique but manufactured with sub-millimetre repeatability.

Another designer operating an online storefront scales global sales through Shapeways’ automated fulfilment: every order is printed, finished and shipped under their brand, with no physical inventory or tooling cost. In both cases, the ability to move seamlessly from one-off creation to continuous production is redefining the economics of bespoke manufacturing.

Their common denominator is not artistic expression but manufacturing reliability utilising the same quality systems, inspection processes and traceability that power Shapeways’ industrial customers.

Across Industries: The metrics of modern manufacturing

While all of these cases differ, the outcomes share a common pattern:

- 20–50% faster development cycles through rapid iteration and digital validation

- Zero tooling investment and near-zero physical inventory, thanks to on-demand production

- Repeatable quality and dimensional accuracy across batches and materials

- Scalable workflows that extend from prototype to serial production without process change

These are the metrics that define next-generation hardware manufacturing: not hypothetical future states, but measurable, repeatable performance achieved every day by Shapeways’ customers.

Turning proof into partnership

The shift from 3D printing as a novelty to additive manufacturing production as infrastructure has been ongoing for many years. Manufacturers should no longer ask whether it’s possible to print end-use parts; they should seek the quickest route to integrating them into production.

Behind every prototype or part is a partnership built on quality assurance, materials expertise and manufacturing discipline. That’s what enables companies from startups to global OEMs to innovate faster without sacrificing reliability.