We believe that next generation hardware manufacturing represents a seismic shift. We see from our own clients and the companies we interact with that certain specific trends are affecting the industry. These trends are almost universal, but the timing is different across different sectors.

We see shorter product cycles, ‘smarter’ hardware’ shorter more resilient supply chains and commercial and environmental sustainability as key drivers. More than this, we see that the next generation of hardware isn’t just faster and more connected, it’s actually looking more like software.

More and faster is part of the human condition, and so it is that throughout the evolution of manufacturing we have strived for both. Today the cascade of technological innovation is constantly accelerating the development of new products. As such they need to be made more quickly, are upgraded more quickly and require in-use support long-after the OEM has moved on.

As we continue to evolve Shapeways, we’re creating a digital manufacturing ecosystem that keeps pace with the product development and gives all manufacturers the ability to make supply chains more resilient.

Converging expectations

Since 2008 we’ve been able to work with everyone from first-time designers, hobbyists, small- and medium-scale manufacturers through to blue chips and governments. From the outset what each of these groups was looking for was different, but they have also evolved along a similar path in the years since.

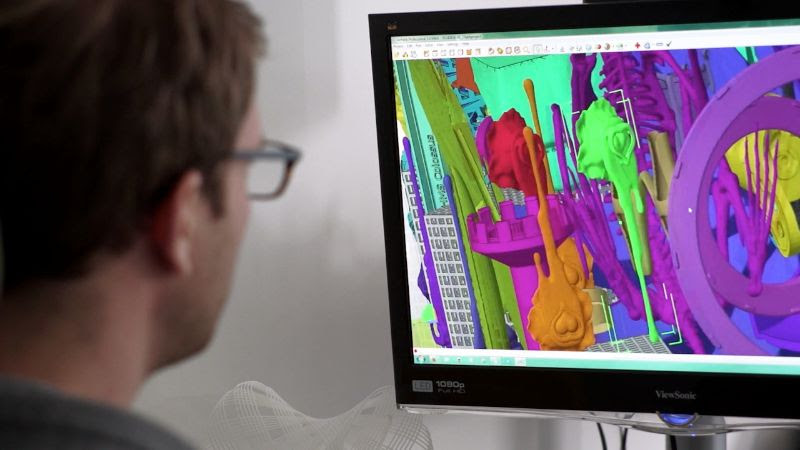

As with any technology we have access to for the first time, the initial projects will be relatively lower in value, with fewer risks. A roll of the dice. For us this was early model making and prototyping depending on the customer. These early use cases (which are still relevant) explored the geometric freedom of 3D printing, and made use of the ability to quickly turn an idea into something tangible… if not the ‘real thing’.

Over time each group has become more confident in the technologies and our ability to deploy them and asked for more from their parts in return. Hobbyists want finer details, colour, materials choices. Companies want more functional prototypes, even quicker turnaround and access to materials and technologies that can realize end-use and increasingly critical parts. With that comes a plethora of other needs: traceability, repeatability, quality control and expansive materials palettes.

What makes next generation hardware different?

Every part exists now as data points before it becomes physical. Traditional manufacturing technologies and associated supply chains and systems don’t always have the ability to leverage that fact. Additive manufacturing as the core technology of a digital manufacturing ecosystem can move more responsively.

New hardware is smarter, leveraging rapid developments in sensing and mobile computing to join the ‘Internet of things’. It’s also more likely to have a distinct software component either onboard, through an app or both. And it will be obsolete more quickly as the integrated electronics elements drive versioning.

A confluence of forces are driving this shift in hardware manufacturing:

- Supply chain concerns — or the ‘dawning of a new supply chain era‘

- Software-first product focus with hardware elements second

- Startups looking to get to market quickly, not set up

- Tariffs and trade barriers changing geographical thinking

Building Shapeways for manufacturing next generation hardware

At Shapeways we’ve always believed that manufacturing needs to keep pace with product innovation, bus is too often a brake. As the world moves toward a new generation of hardware, we’ve focused on building the infrastructure to make that possible: digital from the ground up, agile by design and proven in production over decades.

Our platform connects design, production and delivery in a single digital thread. That means teams can move seamlessly from prototype to production without rework, handoffs or hidden friction. A part designed today can be manufactured tomorrow — locally or globally — with the same level of quality and control. Tomorrow maybe it’s time to scale that up, or down, or switch to the next version.

We’ve spent more than a decade refining the systems, materials and partnerships that make this work at scale. From high-performance polymers and metals to carbon-fibre-reinforced materials, our production network is built for speed, repeatability and reliability. Every part is tracked, measured and verified. Every process is designed to be as responsive as the companies it serves.

For engineers, designers and product leaders we deliver flexibility. The ability to experiment, to produce what you need when you need it, and to trust that it will perform as expected. For businesses, it means manufacturing that can finally move at the speed of hardware development and the confidence to build what comes next.

Building for the next generation of hardware

The shift is already underway. Every year, the distance between idea and physical product grows shorter. The most forward-thinking companies are no longer asking if they can make something, but how quickly they can make it, validate it, and get it into customers’ hands. That’s what the next generation of hardware demands: a manufacturing model that moves at the speed of design.

At Shapeways, we’re focused on building the digital manufacturing infrastructure that enables that agility. One where production data, materials science and supply-chain resilience work together as a single ecosystem. Where a part can move from CAD to production to global distribution without the friction, waste or delay that used to define physical manufacturing.

Hardware will always be physical — but how it’s made is becoming increasingly digital. The companies that embrace that shift will lead the next generation of products, industries and ideas.

We’re here to help them make it real.