-

-

-

Manufacturing

- Materials

- Industries

- ABOUT

- Get a Quote

- Get a Quote

-

My Shapeways

-

Manufacturing

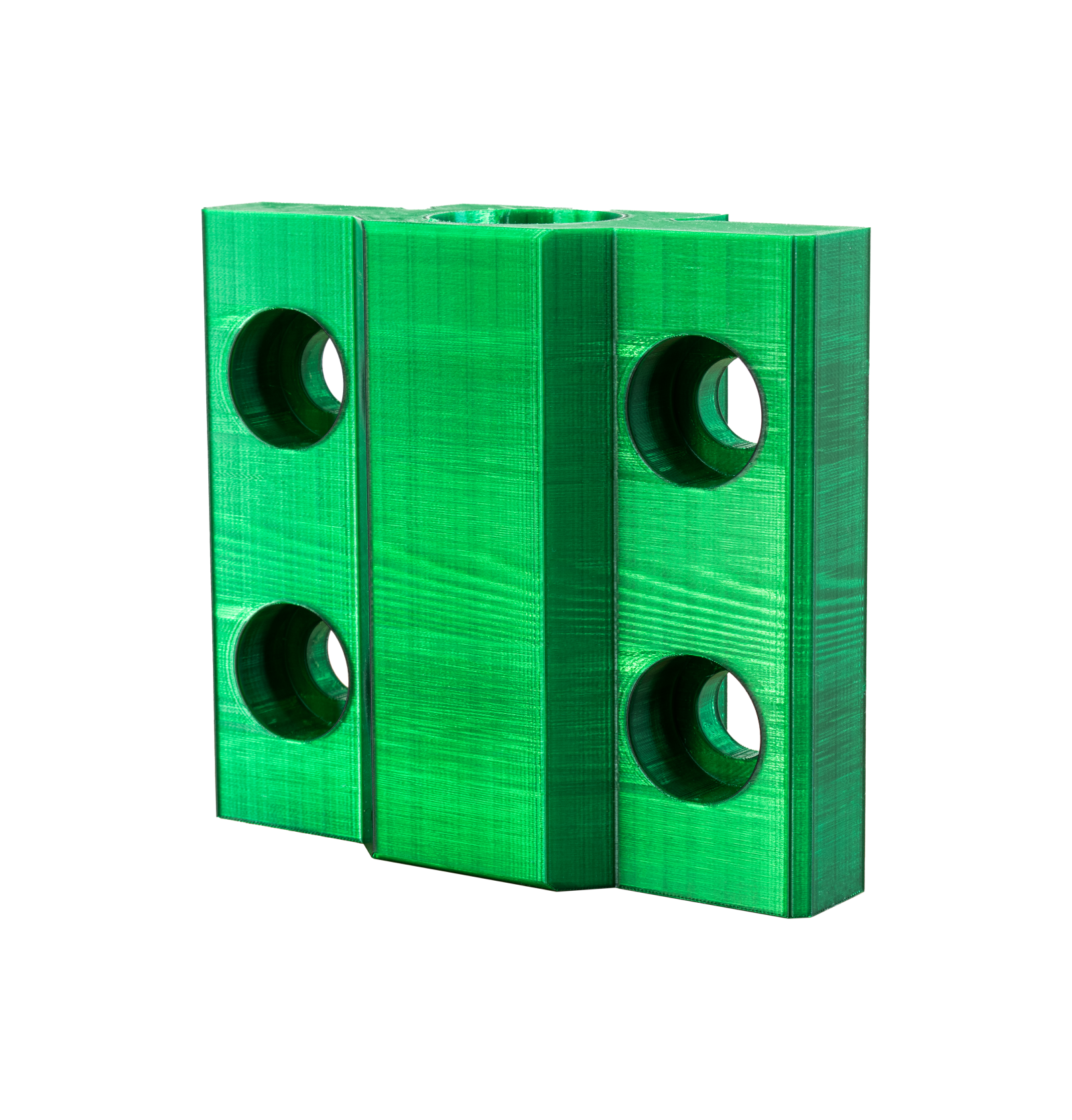

Carbon-fiber-reinforced polyphenylene sulfide (PPS-CF) pairs carbon-fiber stiffness with PPS’s inherent flame retardancy and chemical resistance for harsh, high-temperature use. It prints with a fine, low-sheen matte that often hides FDM layer lines better than ABS/PLA. Low moisture uptake and stable dimensions make it a strong choice for connectors, chemical-handling components, interior hardware, and high-temp fixtures.

Parts are oriented by our team to balance strength, surface finish, and minimal supports. Final orientation is chosen for the best overall result.

Black

Black

Maximum Bounding Box

500x500x500 mm

Please note that parts exceeding 300 mm in any dimension will incur additional costs.

Minimum Bounding Box

10 x 10 x 1 mm

The bounding box is a 3D imaginary outline of a box that encloses the smallest area occupied by your model. Your model must be within the minimum and maximum bounding box sizes. If the size of the model is close to the maximum bounding box, then the printing orientation will be restricted.

A supported wall is connected at least on two sides of the wall, while an unsupported wall is connected only on one side of the wall. Walls that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wall geometry of the model. Please consider the size of your model and reinforce the walls or add support structures as needed as minimum guidelines will not always be adequate for large models.

1.5 mm

1.5 mm

A wire is a circular, rectangular or even triangular feature that is thinner in its unconnected directions than its length. A supported wire is connected at least on two sides of the model, while an unsupported wire is connected on one side of the model. Wires that do not meet the minimum requirements may not survive printing and cleaning processes. Additionally, models may still be rejected based on the wire geometry of the model. Please consider the size of your model and reinforce the wires or add support structures as needed as minimum guidelines will not always be adequate for large models.

0.2 mm

0.2 mm

For text, the ratio between width and depth, should be 1:1 and sans-serif fonts are preferred for line weight consistency.

0.5 mm

Clearance is the space between two individual parts in a model. If the space among the individual parts do not meet the minimum clearance, then parts can fuse together or can be difficult to clean. This is important for movable pieces like hinges, gears, etc.

Interlocking

Supported

Enclosed

Not supported

±0.3 mm or ±0.3% of the nominal dimension, whichever is greater.

"*" indicates required fields

From product development to industrial 3D manufacturing, we can help you scale your business.

contact sales