Every major industrial era has been enabled by its materials. Iron and steel defined the mechanical age; Silicon is powering the digital one. Now, as manufacturing redefines itself around the needs of next generation hardware, materials are again taking centre stage.

Across the additive manufacturing industry, materials innovation in chemistry, formulation and processing are changing what’s possible. High-temperature polymers rival metals in performance, bio-derived resins and recycled powders cut carbon without compromising strength. Hardware is evolving, but it’s the material that decides whether an idea moves from CAD and becomes a product.

Next generation hardware will demand flexible manufacturing methods that both deliver the right parts today and have the flexibility to handle whatever comes tomorrow.

Materials are the limiting factor… and the opportunity

Since its inception additive manufacturing was constrained by material performance. The parts often looked impressive, but most weren’t certified or consistent enough for true end-use applications. The breadth of materials was no where near that for other established manufacturing technologies in both polymers and metals.

That’s changing. Today, new formulations are achieving mechanical properties once reserved for injection-moulded plastics and cast metals. Enhanced repeatability that makes them suitable for production runs, not just prototypes.

Manufacturers are also beginning to think about how to best use what’s available instead of demanding the ‘old’ material. Engineers now ask whether the available material delivers the thermal, chemical or mechanical behaviour the application demands. Those who find the right match are gaining the ability to localise production, simplify supply chains and deliver tailored parts on demand.

It’s something of a quiet revolution: less visible than a new machine launch, but far more consequential.

Our approach

Shapeways has long been at the intersection of that shift. Our platform is built not only on machines, but on the materials that run through them. Every new addition to our portfolio is guided by a simple principle: allow more challenges to be tackled with additive manufacturing.

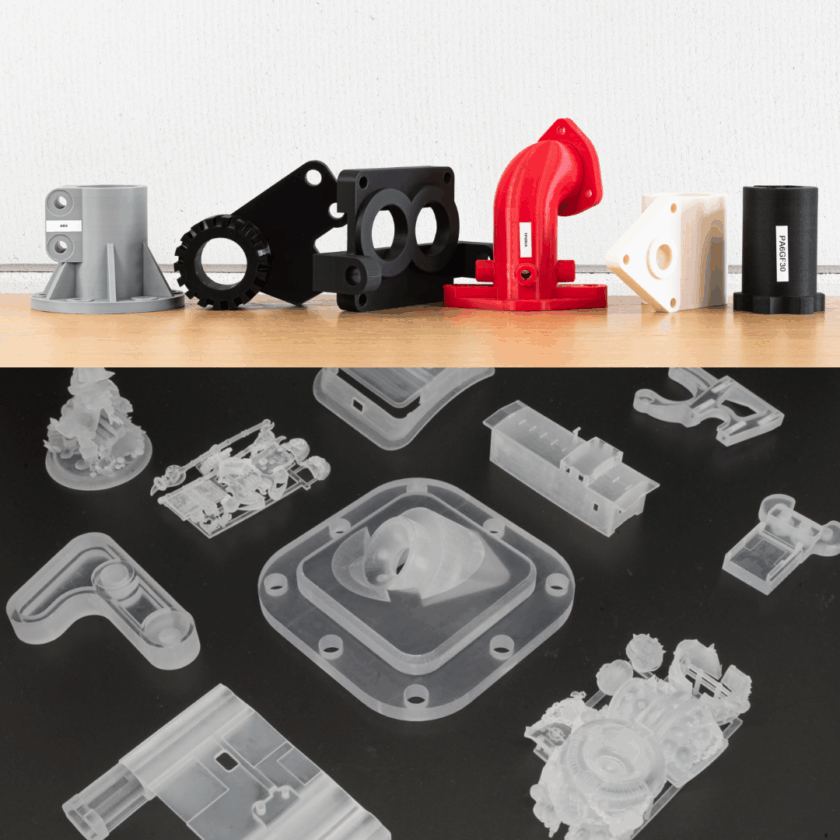

The latest expansion introduces four industrial-grade materials that continue this trend: SAF™ Polypropylene (PP), SAF™ Nylon 11 (PA11), Somos® Watershed Black, and Somos® Watershed XC 11122. Each arrives with distinct properties that open new doors for designers and engineers.

Polypropylene brings one of the world’s most common manufacturing polymers to the table. It is lightweight, fatigue-resistant, and chemically stable, ideal for components that flex, seal or interface with liquids. Nylon 11 adds impact resistance and ductility, making it suitable for protective housings, flexible joints and structural parts that need to survive repeated loading.

The two Somos materials extend our reach into visual and optical territories. Watershed Black offers a fine surface finish and strong dimensional accuracy for housings and enclosures where aesthetics matter. Watershed XC pushes into transparency, enabling light guides, lenses, and fluidic devices where clarity is functional, not decorative.

Additive manufacturing materials innovation is pushing design envelopes

The latest FDM additions (PPA-CF (carbon-fibre-reinforced polyphthalamide) and PPS-CF (carbon-fibre-reinforced polyphenylene sulfide)) continue the materials innovation momentum. Both are designed for demanding environments where heat, chemicals and mechanical stress rule out standard polymers.

PPA-CF delivers strength, stiffness and dimensional stability at roughly half the weight of aluminium, with heat deflection temperatures (HDTs) up to 188°C, making it ideal for structural brackets, housings and lightweight tooling. PPS-CF goes even further, with HDTs around 252°C, UL 94 V-0 flame retardancy and excellent chemical resistance. This combination is suited to automotive, aerospace, industrial and electronic components exposed to harsh conditions.

Each of these materials represents more than another SKU in a catalogue — they are building blocks for products that can move quickly and directly from digital concept to industrial production, without compromise.

Why material innovation defines the next era

The big picture is that the frontier of additive manufacturing no longer lies in the mechanics of printing, but in the materials science of what’s being printed.

As the resilience of global supply chains continues to be questioned, trade barriers erected and manufacturing increasingly seen as a national security issue the ability to produce stronger, lighter and more localised parts is becoming a competitive differentiator. The companies that thrive in this environment will be those that embrace the palette of materials available to them and embed them in their design logic.

That’s what Shapeways’ Next Generation Hardware vision captures: a future where performance and production agility converge, where materials innovation turns digital flexibility into physical reality.

The machines will keep improving of course, but it’s the material that sets the pace. Every new formulation expands the boundaries of design and reshapes how products are made, distributed and maintained. In that sense, materials aren’t just part of the story of Next Generation Hardware, they’re the foundation of it.