With the ability to significantly improve quality of lives and in some cases save them, medical additive manufacturing is a key tool used by many medical professionals.

3D Printed Medical Models and Tools

Successful treatment begins with gathering as much information as possible about a patient and their physical condition. While the ability to see inside the human body before surgery previously relied solely on X-rays, computed tomography (CT) scans, and magnetic resonance imaging (MRIs), diagnostics have been expanded much more fully with 2D data converted into complex 3D printed medical models.

3D printed medical models serve multiple functions. Once a diagnosis is attained, the 3D printed medical model offers advanced guidance for treatment; for example, a detailed anatomical model may display a tumor in the chest, a defect in the heart, or deformations in major joint areas like the knees or hips. At that point, doctors have the benefit of using 3D printed models as powerful visual aids to educate patients and their families, demonstrating what a possible medical procedure or treatment plan may entail.

The learning benefits are extensive with 3D printed models, to include extremely valuable training for medical students who are able to view a tumor, for example, and then practice what could be a new or rare surgical procedure. An experienced surgeon may also rely on the 3D printed model for the duration of the treatment, practicing and training extensively for the procedure.

3D printed medical models are becoming increasingly more common in pre-surgical planning, and in the operating room. Surgical guides lead to elevated confidence and even better accuracy on the part of the surgeon, also reducing the amount of time spent in the operating room.

Shapeways recommends the following materials for 3D printed medical models:

High Definition Full Color – One of the most exciting options for photorealistic 3D printed medical models, this material is available in ten million colors, with options available for Standard or Matte finish. Produced via Material Jetting (MJ) technology, anatomical models 3D printed with High Definition Full Color represent human organs in exacting detail. Find out more about the design guidelines for this material here.

Multi Jet Fusion PA12 – Also suitable for the creation of complex medical models, this versatile material 3D printed with Multi Jet Fusion offers both strength and durability—both important characteristics for parts that tend to be handled a lot over time. MFJ PA12 is available in Black and Gray, with options for Natural or Smooth finish. Find out more about the design guidelines for MJF PA12 here.

Customized 3D Printed Medical Devices and Implants

While medical models make patient-specific treatment possible, 3D printed devices such as implants are actually custom-fitted to patients, eliminating the one-size-fits-all mentality. A diverse number of 3D printed devices are available via advanced technology and materials, and the greatest benefit is still centered around the ability to offer substantially greater form and fit with personalization. These advantages are especially evident when a newborn’s life is saved with a 3D printed implant, a high-performance prosthetic is used as a limb replacement, or surgeons are using new 3D printed training tools for complex medical procedures.

For prosthetics and orthotics, the additive manufacturing process begins with a quick 3D scan. With perfectly calculated form, a 3D printed part is made-to-fit for the patient. Whether 3D printing orthotics or prosthetics, this process is extremely helpful for children who may not only have an exceedingly difficult time remaining still for long fittings, but are also growing at such a rapid rate, they could outgrow a device before it is even delivered. While the 3D design and printing process is exponentially faster, if changes must be made there is a huge difference between having to order a completely new device or just making a swift modification to a 3D file and making another 3D print.

Shapeways recommends the following materials and technology for 3D printed orthotics and prosthetics:

Nylon 11 [PA11(SLS)]- 3D printed with Selective Laser Sintering (SLS), this material is durable and offers good resistance to impact as well as high tensile strength. Nylon 11 [PA11(SLS)] is offered in White, with a Standard finish. Explore the design guidelines for this material further here.

Nylon 12 [Versatile Plastic] – Also relying on SLS 3D printing, this material is extremely durable and adaptable, whether parts require rigidity or flexibility. Nylon 12 [Versatile Plastic] is available for dyeing in eight different colors with a variety of finishes ranging from Standard to Premium and Smooth. Explore the design guidelines for this material further here.

Multi Jet Fusion PA12 – Also suitable for prosthetics and orthotics, this versatile material 3D printed with Multi Jet Fusion offers strength and durability—both important characteristics for parts that tend to be handled a lot over time. MFJ PA12 is available in Black and Gray, with either the Natural or Smooth finish. Find out more about the design guidelines for MJF PA12 here.

3D Printed Gamified Learning with Robotics for Surgeons

Although 3D printed medical models play a tremendous role as educational visual aids, companies like Flamingo Works have expanded on learning for surgeons by 3D printing extensive platforms that are set up like colorful games. Advanced enough to challenge doctors into climbing to the next level, gamified learning builds on the dexterity required for complex, robot-assisted medical procedures.

Designing for Nylon 12 [Versatile Plastic] with SLS technology, founders Yonatan Assouline and Naty Moskovich developed the concept for their unique 3D printed educational tools after a long-time robotics client approached them to make a simulator for robotic surgery training. Taking a new approach, the industrial design team aimed to avoid the typical anatomical cadaver-like training with silicone. Instead, they chose small, open platforms to create challenging exercises for surgical mastery of robotic grippers.

3D Printed Organizational Tools for the Medical Setting

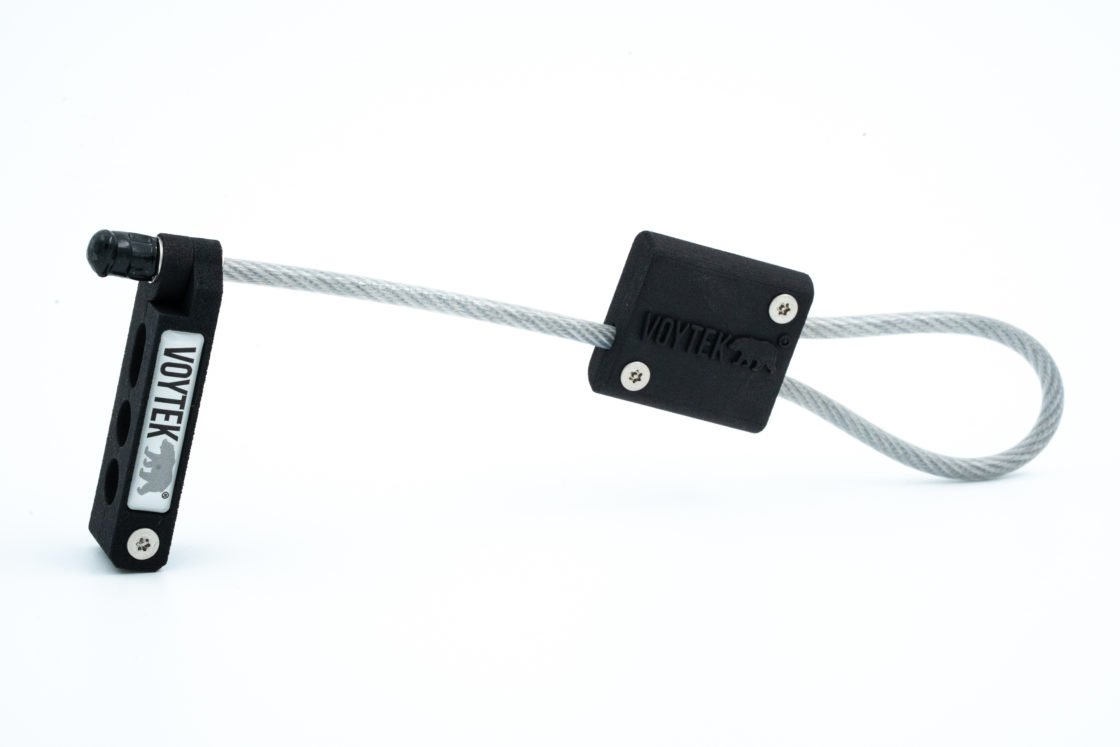

Exemplifying just how many roles 3D printing can take on in medical applications, Voytek Medical has made a real case for the importance in organizing detachable medical equipment cable. Anyone who has ever been in a hospital is familiar with the plethora of cords scattered around and in constant use.

Partnering with Shapeways to design and 3D print clasps for locking medical cables in place, Voytek founder Steven Jaworski was able to offer a real solution for hospitals to better manage and maintain critical medical equipment. Rapid prototyping also played an important role as Jaworski perfected his innovative products, improving workflow for medical professionals who now no longer have to worry about finding or piecing equipment together during a patient emergency.

3D printing has made its mark in a multitude of diverse, global applications, paving the way for innovation and unprecedented product development.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.