In the relatively early days of additive manufacturing, S&S co-founders Tim Sheehan and Mark Sears ran Figulo, a manufacturer of ceramic 3D printers that served both the design community and emerging B2B customers. One of their first major relationships was with Shapeways.

Now, more than a decade— and several business ventures — later the two companies are reconnecting. Today, S&S Machine is a modern precision machining company serving a select group of customers in pharmaceuticals, consumer goods and defense. And as S&S looks to expand its capabilities and deepen those customer relationships, additive manufacturing is back on the table and powered by Shapeways.

“We always had a strong and trusted relationship with Marleen,” says Tim. “So when we decided to expand into AM again, Shapeways was our first call.”

A new chapter built on trust

S&S isn’t chasing scale for scale’s sake. The team’s philosophy is deliberate: fewer customers, deeper relationships, broader capability.

That’s where Shapeways fits in. The idea isn’t to overhaul how S&S works — it’s to add an invisible layer of capability that helps them say ‘yes’ more often.

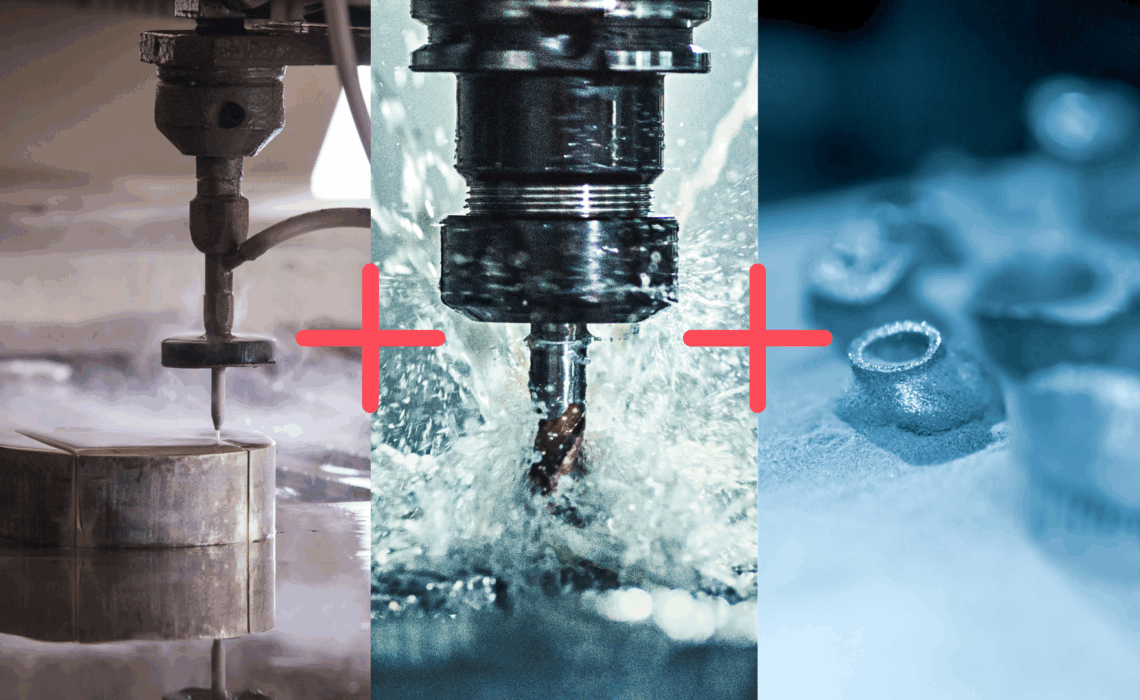

“We’ve got the ability to machine and waterjet and assemble,” says Tim. “Now we want to be able to say, ‘Yes, we can do additive too.’”

Their first test jobs with Shapeways are some 3D printed plastic components for a medical device customer. But the opportunity goes further. S&S is exploring ways to integrate additive into its quoting, prototyping and early production offerings.

“Sometimes I just don’t have the capacity to turn a part around next week, so access to AM gives me another lever to pull.”

From prototype to production selectively

While S&S can’t handle high-volume runs in-house, they’re well-positioned to manage the early stages of product development. With Shapeways in the mix, they can offer digital manufacturing from day one — without overstretching their internal resources.

“If we’re specced in to make your prototype, there’s a good chance we can help you build the first hundred parts too. Additive just extends that runway for us and offers flexibility for our clients.”

While the possibilities are almost endless, the current focus is on offering AM as a service to their core customers —many of whom don’t even realize yet that S&S has access to those capabilities.

Sharing histories and futures

The connection between the two companies has evolved with the industry. Back when Tim and Mark sold Figulo to 3D Systems, the landscape was flooded with hype. The positive and negative lessons from that era have shaped how S&S operates today.

“We’ve seen a lot in this industry. Shapeways today feels like it’s being rebuilt the right way — dependable, responsive and built for business.”

It’s early days, but the intent is clear: this isn’t just a vendor relationship. It’s a strategic alignment, built on trust and a shared understanding of where the industry is heading.

“We’re not chasing thousands of customers. We’re building deeper relationships — and additive helps us do that.”

Are you a machine shop or manufacturing service provider looking to say “yes” more often?

Join the growing network of trusted partners integrating Shapeways’ additive capabilities into their offerings quickly and without the overheads. Whether you’re expanding your prototyping services, filling capacity gaps, or building out digital workflows, we can help you add AM where it counts. Reach out to [email protected] to explore what it means to become a Shapeways reseller.