A new era for 3D creators begins with the Thangs Marketplace, powered by Shapeways manufacturing.

When we announced the closure of the Shapeways Marketplace in 2024, we knew it marked the end of an era for thousands of creators who built their businesses with us. However, our belief in the power of designers, makers, and small businesses that bring innovation to life through 3D printing has never wavered.

Over the past year, we’ve been working behind the scenes to make that creative ecosystem stronger than ever. Today, we’re excited to share where it’s headed next.

Introducing the Thangs Marketplace — Powered by Shapeways

We’ve partnered with Thangs, the world’s fastest-growing 3D model platform and community, to create a new home for creators and shoppers. The Thangs Marketplace now integrates directly with Shapeways manufacturing, enabling designers to upload, print, and sell their products just as before, but with increased flexibility and reach.

Through this Shapeways & Thangs partnership, creators can:

- Sell 3D-printed products and digital designs, offer physical products printed by Shapeways, or sell downloadable 3D models for home printing.

- Earn recurring revenue through digital memberships and exclusive subscriptions.

- Set up quickly with easy onboarding via Thangs, Stripe Express payments, and optional printability review powered by Shapeways’ quality standards.

If you were a Shapeways Shopowner, create an account on Thangs, fill in your profile, upload your models, and submit for designer approval and note in your profile that you’re a former Shapeways designer – helping us to ensure you get the support you need and reconnect the community you helped build.

👉 Start here: Sell 3D printed products and designs

For Shoppers and Makers: Discover Unique 3D Products

The new Thangs shopping experience makes it easier than ever to explore and purchase 3D creations from top designers worldwide. You can:

- Shop custom 3D-printed products made and shipped by Shapeways.

- Download 3D models for your own home printer or creative projects.

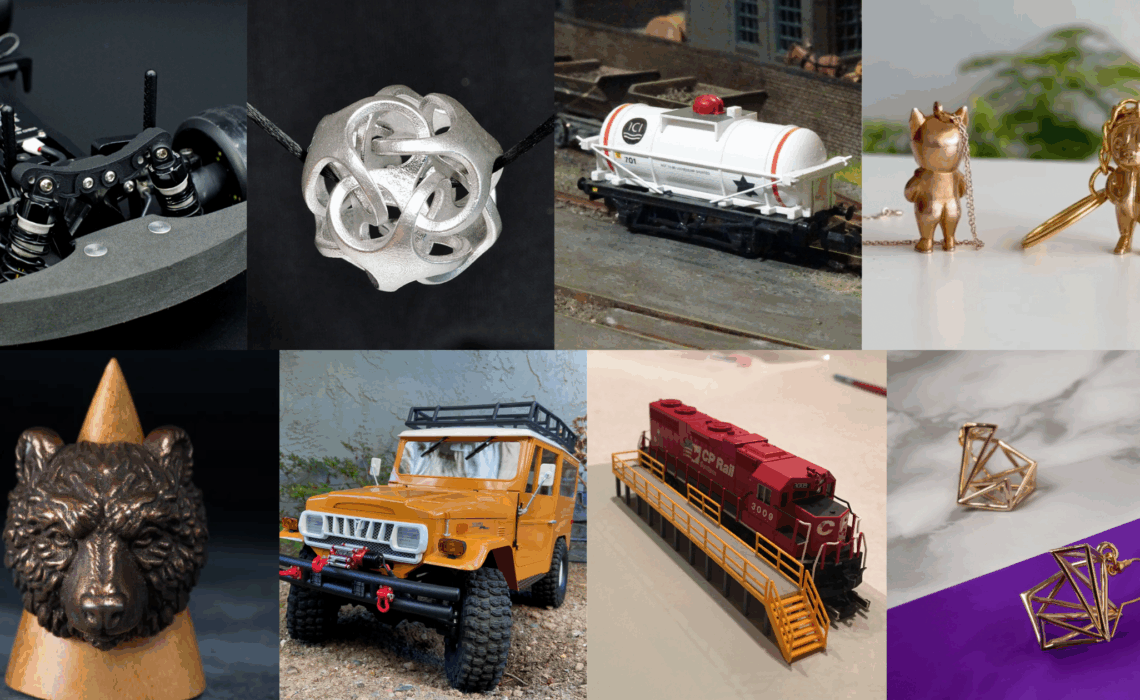

- Browse categories like jewelry, collectibles, toys, games, and engineering models, all backed by Shapeways’ quality manufacturing.

Whether you’re a maker seeking inspiration or a shopper looking for something truly unique, the new 3D marketplace seamlessly bridges creativity and production.

Continuing the Shapeways Mission

As Shapeways continues to power production for next-generation hardware and 3D printing, we’re proud to see Thangs extend the legacy of the Shapeways Marketplace: empowering creators to turn digital 3D models into real-world products.

This collaboration brings together Shapeways’ manufacturing expertise with Thangs’ vibrant community of designers, ensuring that innovation and creativity continue to thrive. It marks the next chapter for the global 3D creator community, where design meets digital manufacturing.

Explore. Create. Sell. Print.

The future of 3D design commerce starts here: 👉 Shop and sell on Thangs, powered by Shapeways manufacturing.