3D printing and robotics are one of the most complementary pairings for technology and manufacturing. Pointing the way toward greater automation and speed in production, robotics are beneficial for countless industrial tasks. The addition of 3D printing allows companies to maximize these advantages in advanced applications like medicine, with the use of innovative tools like a 3D printed robotic arm in complex surgeries.

Making its way into rudimentary manufacturing techniques as early as the 1950s, the field of robotics was slow to catch on. Throughout the years, as it became apparent that robots could take over many simple automated tasks previously performed by humans, 3D printed robotic arms were commonly built to replicate the human arm on the assembly line.

A 3D printed robot can eliminate repetitive, tedious work for humans, leaving them available to do more complex and valuable work. Projected to grow into an industry worth $260 billion by 2030, robotics are now firmly ingrained in industrial manufacturing.

Additive Manufacturing for Robotics Boosts Iteration

Advanced industrial engineers realize 3D printing as a robotic process in itself, with the capability to 3D print robots that can then make 3D printers too, perpetuating 3D printed parts into infinity. Just as important though is the ability to improve and accelerate part development of nearly any robotics design or product.

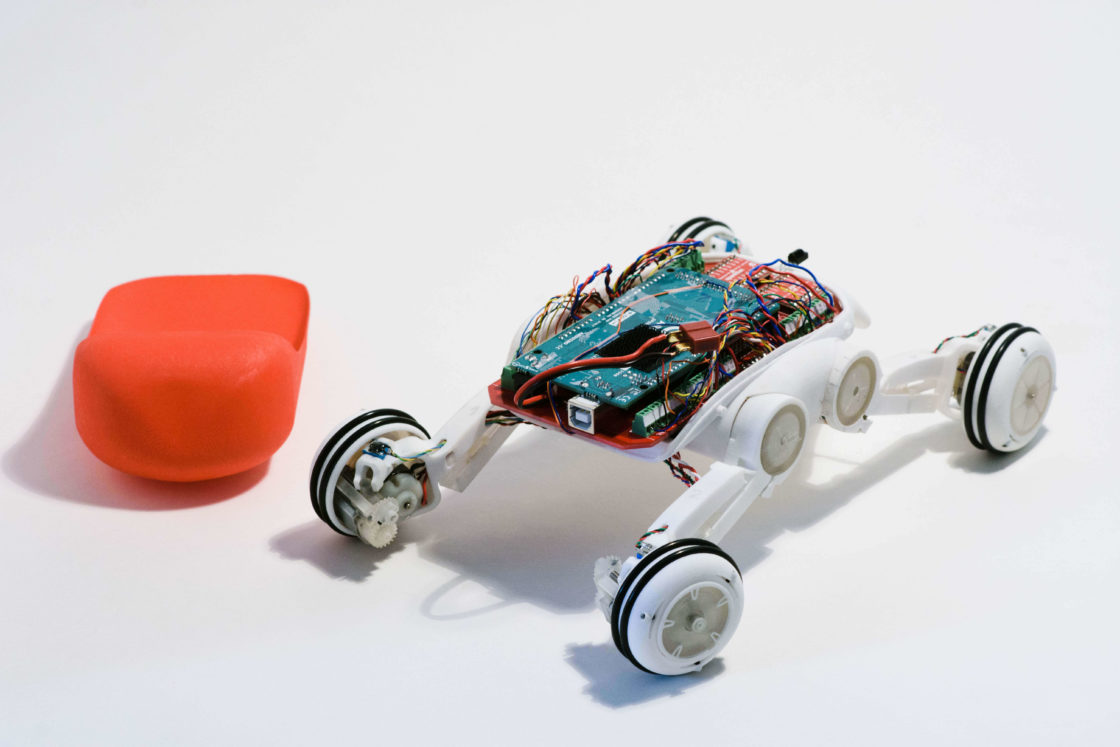

The intensive journey any business embarks on when developing a new product or improving an existing one can be streamlined with rapid prototyping via 3D printing, and even more so in transforming robotics. Changes can be made quickly to any model or prototype, in comparison to traditional manufacturing where innovators may encounter long wait times, delayed feedback, and the inability to make desired changes. No matter how extensive or rigorous project requirements may be, rapid prototypes for parts like a 3D printed robotic arm can be sent back to designers and engineers with valuable suggestions and the option for unlimited iterations.

Shapeways customers may iterate over a hundred times while perfecting a complex part or product, working with different materials like like Nylon 11 [PA11(SLS)] or Nylon 12 [Versatile Plastic] and extremely adaptable technology like Selective Laser Sintering (SLS). Even in taking the time to create numerous models for testing and feedback, customers find that prototyping robotics with 3D printing is exponentially faster than with traditional manufacturing, harkening back to the technology’s original and continued use. The process is substantially less expensive, allowing for increased focus on product development.

From Uploading 3D Models to 3D Printing End-Use Robotics

Once a customer uploads a 3D robotics design to Shapeways, the model is analyzed for 3D printability; for example, while most 3D models are printable, others may have compatibility issues regarding materials and a complex geometry–or there may be other common issues with wall thickness, textures, engraving and fonts, and more. This process, supervised by the User Application team at Shapeways, ensures accuracy regardless of the scale of prototyping, and whether modeling full-size 3D printed robots or smaller operating 3D printed robotic arms.

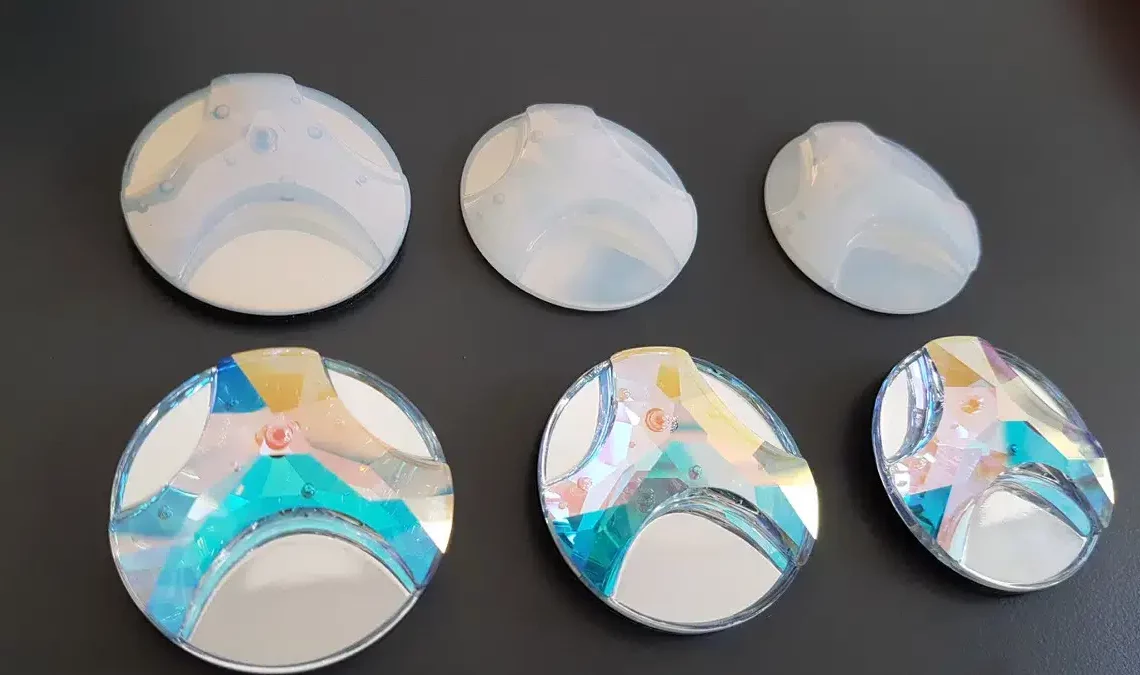

Customers like Flamingo Works use the same additive manufacturing materials and technology for prototypes as well as functional simulators and 3D printed robotic grippers. Materials like Nylon 12 [Versatile Plastic] and SLS 3D printing are repeat choices because of the unprecedented design freedom for prototyping and also for creating end-use parts for the mechanisms that train surgeons in robot-assisted surgeries. Nylon 12 [Versatile Plastic] also presents the adaptability required for prototyping and the durability necessary for parts that will be used repetitively with 3D printed medical training simulators.

Advanced 3D Printing Technology for Mass Customization and Reduced Assembly

SLS 3D printing allows for sizable robotic parts to be made in either large, singular pieces or substantially reduced assemblies. Structures can be made stronger, yet lighter in weight. SLS robotics 3D printing is versatile for any type of build, whether making small customized parts or complex systems with gripping and grabbing parts.

Mass customization is a critical benefit, along with 3D printing robotics on demand for manufacturers who may be tired of keeping large stores of inventory. The overall result, whether prototyping or manufacturing high-performance 3D printed robotics, is maximized efficiency, higher quality and optimization of parts, and less use of materials and energy. In partnering with Shapeways, the supply chain is streamlined and improved, offering robotics manufacturers more control over distribution.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.