Nylon 12 is one of the most popular 3D printing materials today, serving as a powerful option for Shapeways customers over the long term, offering benefits over other popular materials like PA12. As their 3D printing needs and project requirements grow, advanced materials and Nylon 12 3D printing properties have continued to evolve too.

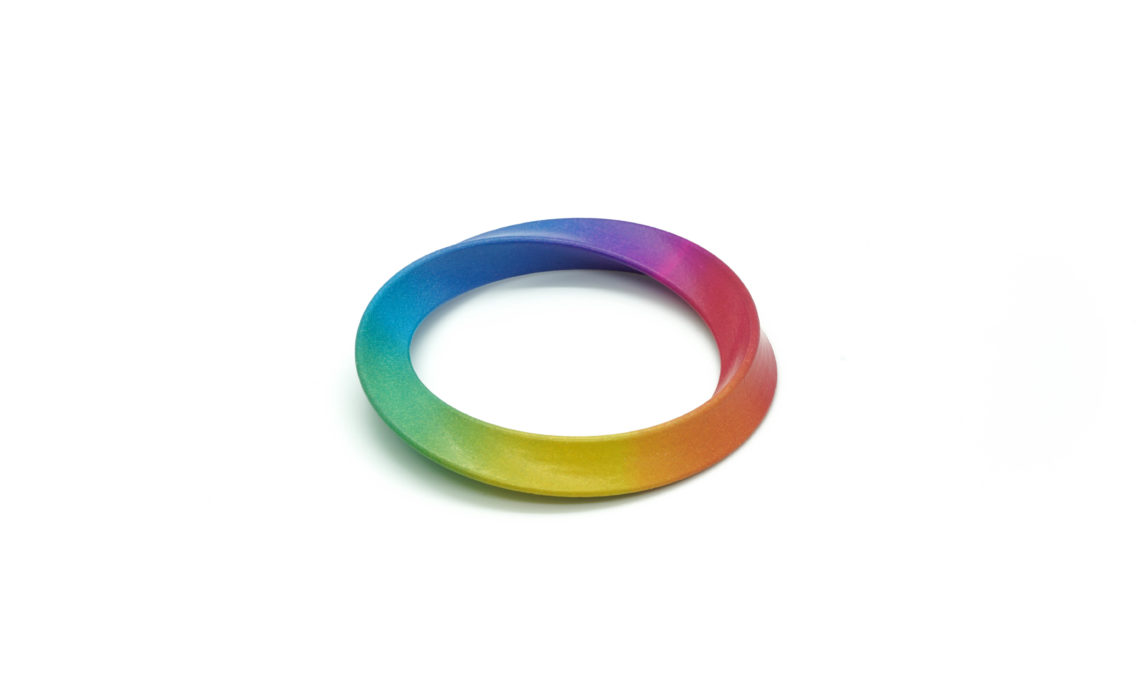

Shapeways now offers Nylon 12 in Full Color with Multi Jet Fusion, streamlining manufacturing with ultra-fast production for functional parts. Multi Jet Fusion allows manufacturers to accelerate the product development process with streamlined, rapid prototyping as well as creating industrial, high-performance products in full color.

Key Benefits to Nylon 12 3D Printing

Nylon 12 Full Color (MJF) possesses superior mechanical properties, dimensional stability, and good resistance to impact–as well as chemicals like oil, grease, and more. Defined by the capacity to deform under tensile stress, Nylon 12 Full Color (MJF) is flexible for structures with a thinner design but becomes rigid for use with thicker parts, offering the durability and density required for end-use parts.

The drawbacks in 3D printing with Nylon 12 Full Color (MJF) are few, while the advantages abound, to include:

- Improved aesthetics and use in tasks like instruction labeling

- Ability to print moving parts

- Greater strength over other methods because thermal energy is so deeply absorbed

- Sustainability in resources as material powder is easily recycled from one build to the next

- ISO 10993 Skin Contact Safe

Manufacturers come back to this material repeatedly due to the quality in parts, but also because the potential is unlimited–whether they are engaged in product development or 3D printing high-performing, functional parts.

Multi Jet Fusion 3D Printing Technology

Manufacturers enjoy greater freedom in engineering and design of parts because support structures are not required for MJF 3D printing. As a result, hundreds or even thousands of parts can be nested together in one build. The smart packing process leads to accuracy and repeatability for parts, every single time.

Operating as a subcategory of powder-based additive manufacturing, Multi Jet Fusion technology does not rely on a laser for heat or adhesion of the 3D printing layers; instead, MJF technology uses an inkjet array that moves back and forth depositing adhesive agents onto the powder bed, where the nylon particles are melted with thermal heat. The process is set into motion as a thin layer of powder is dispersed onto the print bed. A fusing agent is then sprayed on the material, heating it. The detailing agent is added around the part, evaporating and cooling the area. Abrupt thermal transitions cause the molten layers to fuse together, resulting in 3D printed parts that are uniformly strong due to evenly dispersed temperatures.

Applications

This versatile material is also available for Nylon 3D print in Natural and Smooth glossy finishes, and is suitable for products like:

- Industrial jigs and fixtures

- Braces and casts

- Moving and interlocking components

- Structural parts and mounts

- Medical models

- Presentation models

- Functional prototypes to test for form and fit

Explore design guidelines for Nylon 12 3D printing properties here.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.