Materials for every stage

of any project

From strong plastics to polished metals, Shapeways’ materials can bring your 3D print ideas to life.

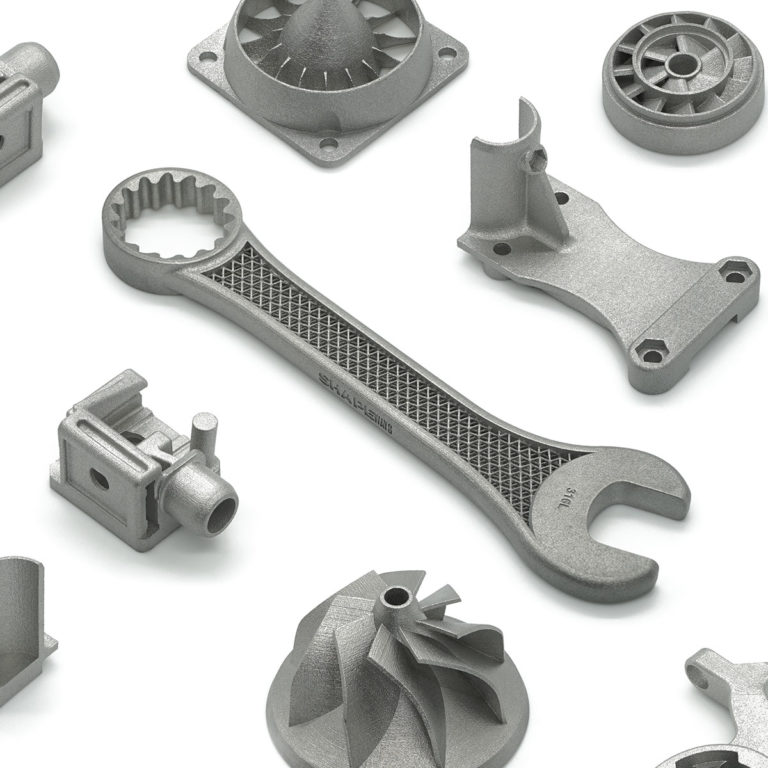

Binder Jetting

In Binder Jetting, a binder is selectively deposited onto the powder bed, bonding these areas together to form a solid part one layer at a time. The materials commonly used in Binder Jetting are metals, sand, and ceramics that come in a granular, powder form.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a popular 3D printing technique that builds objects layer by layer using a thermoplastic filament. The filament is melted in a heated nozzle and deposited onto a build platform, where it solidifies to create the desired shape. Known for its affordability and versatility, FDM is widely used for prototyping, functional parts, and hobbyist projects.

Laser Powder Bed Fusion Metal (LPBF-M)

Selective Laser Melting (SLM) process uses a laser to scan and selectively melt the metal powder particles, bonding them together and building a part layer-by-layer.

Material Jetting

Material Jetting operates in a similar fashion to 2D printers. In material jetting, a printhead (similar to the printheads used for standard inkjet printing) dispenses droplets of a photosensitive material that solidifies under ultraviolet (UV) light, building a part layer-by-layer.

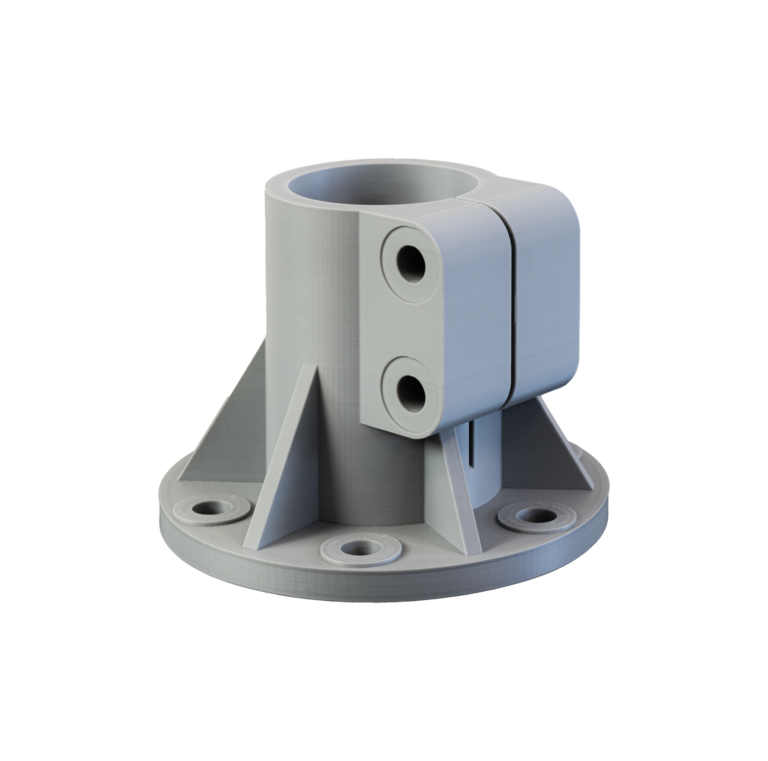

Multi Jet Fusion [MJF]

Multi Jet Fusion (MJF) begins with a thin layer of powdered material being deposited across the build platform. Droplets of fusing and detailing agents are applied along with thermal energy on top of the powdered material to define the part’s geometry.

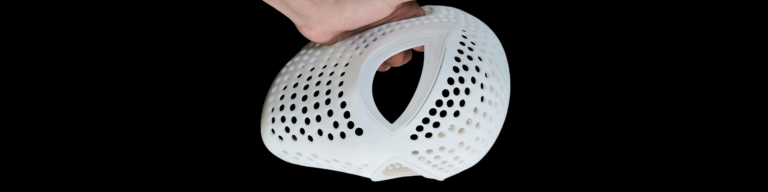

Selective Laser Sintering [SLS]

Selective laser sintering (SLS) uses a laser as the power source to sinter powdered material, aiming the laser automatically at points in space defined by a 3D model, binding the material together to create a solid structure.

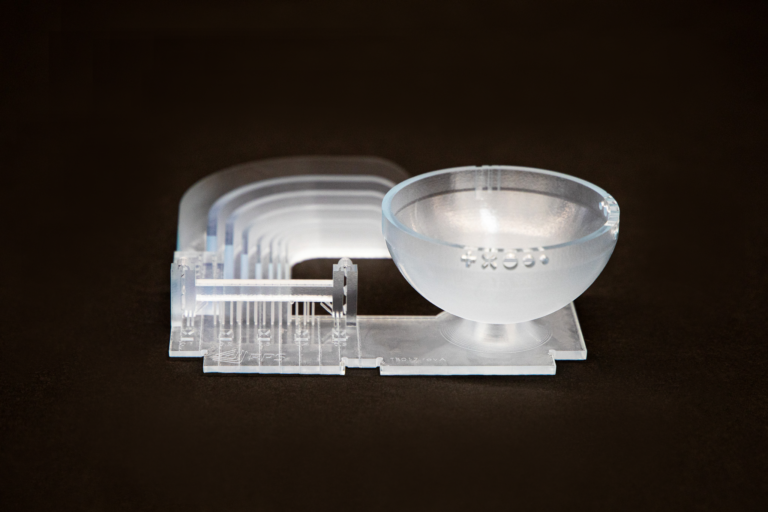

Stereolithography [SLA]

Stereolithography (SLA) creates parts in a layer by layer fashion using photochemical processes by which light causes chemical monomers to link together to form polymers. Those polymers then make up the body of a three-dimensional solid.

Wax Casting

3D printing technologies create a smooth wax pattern, which is used to create casting molds to produce precious metal parts.

Stay up to date on promotions, case studies, and more.

Ready to get started?

From product development to industrial 3D manufacturing, we can help you scale your business.

contact sales