Drones have taken a strong hold among hobbyists and tinkerers, and for these daredevil racers and aerial explorers, 3D printing is a natural fit. But what about the hard-working industrial drones that need to deliver vital information and insights, remotely and at the touch of a button? Kespry, AKA “The Best Drone Company You’ve Never Heard Of” makes the kind of lightweight autonomous drones that can create a hyper-detailed 3D survey of hundreds of acres in just a couple of hours, for end users with no drone experience. The Kespry Aerial Intelligence Platform unifies a set of technologies that, together, represent an industry-leading surveying and mapping solution — but it’s also exceptional for another reason: From day one, each of Kespry’s drones has been built with Shapeways 3D printed parts.

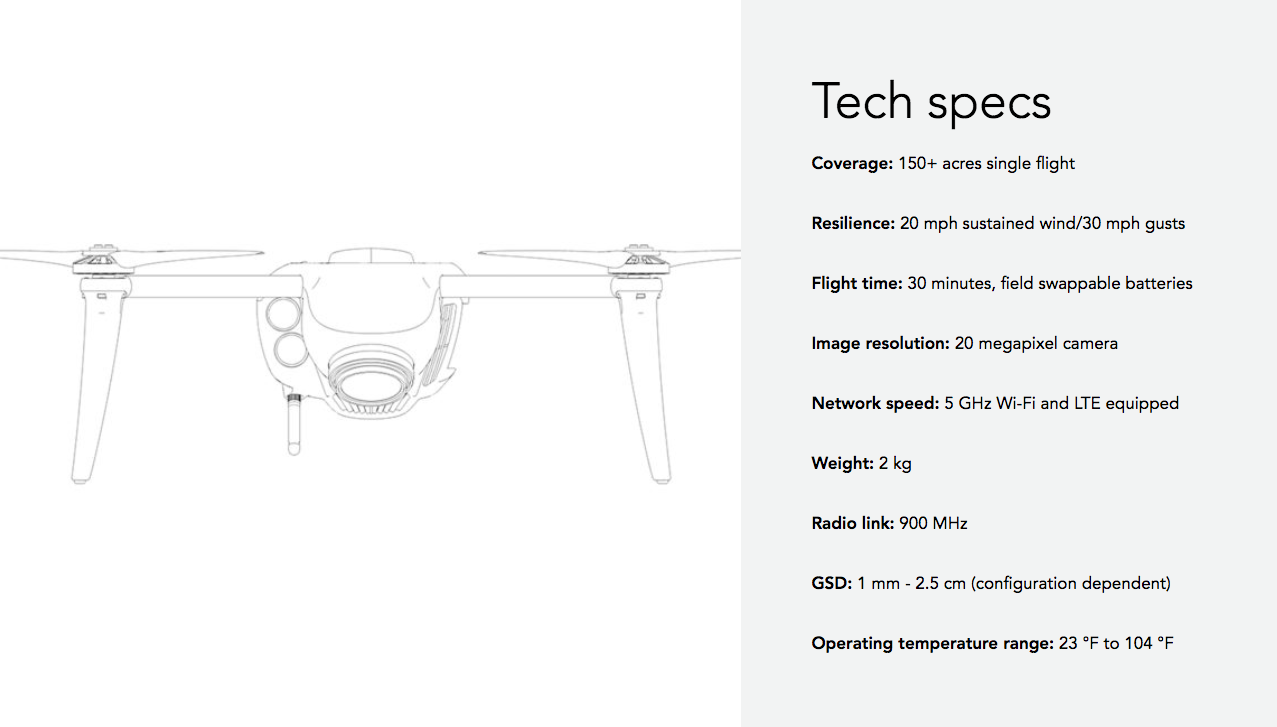

The Kespry Aerial Intelligence Platform, which allows users to design and launch autonomous aerial surveying missions

When you’re pioneering a new technology, affordable iteration and scalability are key. Kespry needed a partner and a process that would help them do something that’s still extraordinary: develop parts using 3D printing, and then integrate those parts into end-use manufacturing. Reliability, repeatability, and proactive support would underpin the success of the collaboration. “We were a very small company trying to scale up our product and get it out to market as quickly as possible. We were looking for a supplier who had reasonable scale and the right combination of lead time and cost,” remembers Jordan Croom, Kespry’s lead mechanical engineer.

Croom came to Kespry, appropriately, from the aerospace industry, where he did additive manufacturing research and development with both metals and plastics. This background prepared him to apply 3D printing in a relatively novel way. “I had a good understanding of what was possible. We were in a unique place to be able to incorporate additive manufacturing into full-scale production, which I think is somewhat rare, even though it’s becoming more common these days. So that was new for me — to be making multiple hundreds of something per order and incorporate them into our production line.”

“We were a very small company trying to scale up our product and get it out to market as quickly as possible. We were looking for a supplier who had reasonable scale and the right combination of lead time and cost.”

Shapeways offered the kind of scalability and reliability that Kespry needed. “When we started with Shapeways, it was before we even had our first customer, and now we have hundreds of drones going out every quarter. And it’s been a smooth transition to get to that point. That’s definitely not true of all of our vendors. Shapeways is one of the few that’s held out throughout that scaling process.”

A look at Kespry’s 3D mapping software, part of their Aerial Intelligence Platform

Affordability and speed play equally important roles in the 3D printing-for-manufacturing calculus. “Leveraging 3D printing and Shapeways allowed us to get things out there faster without paying an exorbitant premium to do it. And it also allows us to make modifications and improvements to our product without interrupting shipping them out to customers. So we can make a change and incorporate it in production in a few weeks, whereas if we were doing injection molding, it would take maybe a couple of months to make that sort of change. Especially now at production scale, Shapeways can handle the quantities that we’re dealing with really well, without long lead times.”

“We do look for that teamwork and responsiveness in a partner, and Shapeways has shown that to us. I would definitely recommend Shapeways to other companies.”

This became particularly important when it came to the aesthetic covers that enclose the drone’s delicate inner workings. “I know for sure that if we’d tried to make an injection mold for that, it would have been exorbitantly expensive for us. We’ve been able to modify it relatively frequently without much cost impact at all because we’re not investing in fixed tooling,” making it possible for Kespry to bring the best possible product to market, faster. “Getting the right partner is definitely important to us. Somebody with repeatable quality, where we know we can prove a design once. We don’t have to worry about it changing or breaking in future orders.”

“Leveraging 3D printing and Shapeways allowed us to get things out there faster without paying an exorbitant premium to do it. And it also allows us to make modifications and improvements to our product without interrupting shipping them out to customers. Especially now at production scale, Shapeways can handle the quantities that we’re dealing with really well, without long lead times.”

Along the way, of course, there have been a few hiccups, but, “If we do have an issue, Neil, our account manager is very responsive, very proactive and patient. I’ll get an email, photos, a description, etc. asking us if it’s ok to ship, if they should reprint them. We do look for that teamwork and responsiveness in a partner, and Shapeways has shown that to us. I would definitely recommend Shapeways to other companies,” said Veronica Espiritu, Kespry’s production buyer.

In the end, the Kespry drone wouldn’t exist without Shapeways’ prototyping and manufacturing support. As Jordan put it, “We’ve been ordering Shapeways parts basically since the beginning. It’s been helpful to work with Shapeways because you’ve been able to scale with us, going from just a few parts a week to hundreds per month. Shapeways has been able to absorb the increase in demand. I think it’s reflective of both Shapeways and the state of the industry and technology that we’re able to do that in a reliable and repeatable way — without having any negative effect on usability and reliability as a product.”

start growing your drone business with shapeways