Shapeways offers over 90 different materials and finishes, but Nylon 12 [Versatile Plastic] tops the list in popularity. This 3D printing thermoplastic is derived from the family of Nylon 12 materials and other polyamides featuring a long history in traditional manufacturing too. Nylon 12 [Versatile Plastic] and PA12 material continue to trend upward for use in additive manufacturing, whether designers and engineers are engaged in making high-quality rapid prototypes or high-performance parts.

Nylon 12 [Versatile Plastic] – A 3D Printing Standard

Choosing the correct 3D printing material can be the most challenging part of the design and production process. Recommended for a wide range of industrial applications even when comparing Nylon 11 vs. Nylon 12, the overall appeal of Nylon 12 [Versatile Plastic] wins due to high tensile strength, durability for long-term use, and resistance to abrasion, fatigue, and stress.

A Natural matte finish with a slightly rough surface is available, along with a Processed finish which creates a smoother 3D printed surface. More sophisticated finishes for Nylon 12 3D printing are available as follows too:

Shapeways Premium Nylon 12 [Versatile Plastic]

For Premium Nylon 12 [Versatile Plastic], Shapeways employs a multi-step tumbling, polishing, and dyeing process to create a consistent color and surface finish, while removing the grainy feel and layered look of other 3D printed parts. This finish offers an upscale look, elevating designs with a smoother and glossier surface, resulting in a softer texture.

Just saying Premium is smoother can be too vague, so Shapeways performed surface roughness tests. A surface roughness tester quantifies the texture of a surface by measuring the distance between the peaks and values. The larger the distance and the higher the value, the rougher the surface is. Small values indicate a smoother surface. Surface roughness is measured by its Ra value. Ra is the average of these distances between the peaks and values on the surface to its ‘mean line.’ You can think of the mean line as the center line between the peaks and values.

Looking at the values in the table above, the Ra of Shapeways Nylon 12 Premium [Versatile Plastic] measured around 5 micrometers whereas regular Versatile Plastic 3D printing measured around 10 micrometers. This means that the Premium 3D printing finish is about twice as smooth.

Shapeways Nylon 12 [Versatile Plastic] Smooth

This finish has a smooth surface and slight shine, created using a physio-chemical process to vapor smooth the surface.

Accompanied by new choices with Nylon 12 [Versatile Plastic] Smooth, Shapeways customers can design for even more complex structures—whether in product development or for end-use parts. Shapeways achieves this unique Nylon 12 [Versatile Plastic] Smooth finish with vapor smoothing techniques. With this post-processing method, rough surfaces that may be present after SLS 3D printing can be treated effectively. Chemical solvents are applied to the 3D printed parts, which are then placed in a sealed chamber filled with vapor for smoothing.

Selective Laser Sintering 3D Printing Technology

Aptly named, versatility for this 3D printing nylon is primarily due to the combination of Selective Laser Sintering 3D printing and the high ductility associated with Nylon 12 3D printing. SLS technology is one of the oldest and most respected forms of 3D printing, and it remains one of the most powerful. The average build size of an SLS 3D printer is around 300 x 300 x 300 mm with a layer thickness of 100 to 120 microns.

Without a need for supports, expanded design freedom in SLS is a huge advantage. This eliminates the need to make intricate structures for stability during the 3D printing process, making it possible to pack hundreds or even thousands of parts into one build via nesting, and decreasing the potential for damage in post-processing. Nylon 12 [Versatile Plastic] makes it even easier to take advantage of expanded design freedom with ductility necessary for flexibility in thinner parts and rigidity in thicker structures.

Shapeways Customers Inspire with Nylon 12 [Versatile Plastic] for Custom 3D Printing

Shapeways customers choose this material for 3D printing with Selective Laser Sintering (SLS) to make products like: architectural statement pieces, medical models, drones, luxury jewelry, and more. Designers take advantage of the optional finishes and colors too, when applicable, as Nylon 12 [Versatile Plastic] can be dyed in Black, Pink, Red, Orange, Yellow, Green, Blue, and Purple.

3D Printed Architectural Parts with Nylon 12 [Versatile Plastic]

Verner Architects designed a six-foot bathroom vanity for a luxury remodel on a home in California. Verner worked with Shapeways to 3D print the interior statement piece ensuring that durability and water resistance were top of mind.

Due to the print-bed size of SLS technology that Shapeways offers, the architects at Verner were “pleasantly surprised” at the easy assembly of the six-foot-long vanity, 3D printed with Nylon 12 [Versatile Plastic] and coated with polyurethane for waterproofing. Two test prints were performed in-house at Verner Architects, allowing the team to refine the design and structure.

In the architectural and construction fields, 3D printing offers enormous benefits for users engaged in rapid prototyping. Designers are able to create extremely complex models, and make changes easily as they work with their clients. Users today expect many of their 3D printed items to be functional and high performing, with the 3D printed vanity demonstrating just how far the technology has progressed.

3D Printed Medical Models with Nylon 12 [Versatile Plastic]

Uruguay-based Armor Bionics has channeled 3D printing into a technology capable of improving the quality of life for patients, but saving lives too with their unique specialty. Armor Bionics creates intricate 3D designs for medical models that are 3D printed by Shapeways and used for diagnosis, training, and treatment. Armor Bionics CEO Bruno Demuro is dedicated to offering medical professionals better solutions for surgical planning:

“We’ve seen the benefits and how much treatment affects the patients,” said Demuro. “It betters the outcome of every single surgery where it is applied.”

Other industrial design firms like Flamingo Works have collaborated with Shapeways to 3D print colorful simulators using Nylon 12 [Versatile Plastic] to train surgeons in robot-assisted surgeries. Yonatan Assouline, Manager and Co-founder, points out that while the “games” designed for learning may look simple upon first glance, the tasks require practice, medical training, and concentration to excel. This is especially true for surgeons training with robotic grips that shift both forward and reverse to reach objects and complete exercises.

“The training for this technique and the framing of the technology was completely unknown at first,” explained Naty Moskovich, Chief Designer and Co-founder of Flamingo Works. “We were developing 50 to 60 learning tasks at a time, coming up with all sorts of different ideas, and sending them to physicians to see if they liked them or not.

“We would develop one skill and remove another while prototyping. 3D printing with Shapeways gave us the freedom to try out endless new ideas during the product development phase.”

3D Printing in Drone Technology with Nylon 12 [Versatile Plastic]

The aerospace industry is a leader in its use of 3D printed parts, and has for decades—far before anyone knew what the technology could accomplish. Drone technology has taken off in recent years, with a special push via additive manufacturing, allowing engineers to create innovative designs and use lightweight, durable materials with complex geometries. This is especially true for companies like Munich-based Quantum-Systems, specializing in advanced eVTOL (electric vertical take-off and landing) drones.

Using 3D printing for prototyping and manufacturing of functional parts since their inception in 2015, Quantum Systems is able to make lightweight parts, while also taking advantage of “synergy effects” in reducing part counts and assembly.

“Only because of the fact that we have integrated this manufacturing method into our manufacturing and development process, have we been able to significantly reduce development time. For injection molded parts, we save around 10 weeks by using 3D printed samples to release the CAD data,” said Florian Seibel, CEO of Quantum-Systems.

“The probability that these parts need a second loop of corrections is quite low in this way. For CNC-manufactured parts it is the same. We often just skip the first round of samples with 3D printed parts, which saves us three to four weeks. In general, I would say 3D printing saves us 20 to 50 percent of time, depending on which parts we design.”

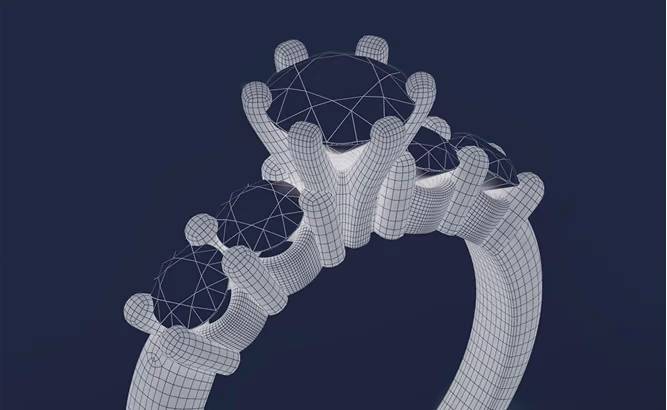

3D Printing in Jewelry with Nylon 12 [Versatile Plastic]

3D printing has a long history with jewelry makers, and especially at Shapeways. Demonstrating the wide range of popularity amongst industrial designers, customers like Groen and Boothman use Shapeways services for 3D printing luxury jewelry like their custom Creatures design series, featuring unique cuff bracelets. The designers rely on the lightweight quality of Nylon 12 [Versatile Plastic], along with the strength and durability of the material.

“3D printing gives us a chance to explore new avenues and get away from the mass production paradigm,” said Joanna Boothman.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.