- 3D printing materials allow for fast, lightweight drones.

- Applications continue to grow for use with 3D printed drones, including surveying, inspecting, and eventually, deliveries to consumers.

- Technology like Selective Laser Sintering (SLS) allows for 3D printed drone frames and parts on a large scale.

Names and descriptors associated with aircraft and technology like drones abound. From aerospace to aeronautics and from aviation electronics technology to autonomous urban aircraft, drones go by a variety of other monikers too: unmanned aerial vehicles (UAVs), human-controlled devices, 3D printed quadcopters, hexacopters, and more. Drones also offer vast new perspectives on the Earth’s terrain, opening up new ways to handle projects and missions globally, as well as within busy cityscapes and more provincial areas.

Humankind may have exhibited an ongoing obsession with the idea of being able to fly, but now we also have the capacity to let machines do some of the work and the flying without us from above, improving life below. With industrial drones, the focus is less on soaring through the clouds to while away the time, and more on expanding productivity like never before.

3D Printed Drone Systems Take on the Difficult Assignments

When the sky really is the limit, people tend to get excited; after all, there is a sense of exhilaration in seeing technology of the future come to fruition, suddenly accessible and affordable. This goes for both 3D printing and drones.

While regulations may be having some impact, drones seem to be evolving at a rate far more sophisticated and accelerated than rulemakers can keep pace with. And in the meantime, large organizations, businesses, and enthusiasts seem to have little trouble embracing the use of drones; after all, the door is wide open to countless opportunities, especially with the capacity to use new methods for gaining valuable information, and the new ability to take action in places that humans may not normally be able to access.

Both semi-autonomous and completely autonomous drones are already in use for a variety of applications, although initial concepts like delivery of consumer goods may still be stalling in comparison to use in the following areas:

- Construction – Because drones can reach building projects from above rather than just on theground, they bring a whole new approach to creating new infrastructure and assisting in reaching architectural structures at elevated heights.

- Delivery – The transport concept is particularly exciting not only because consumers love the idea of retail products being dropped right on their front lawns, but also because critical items can be delivered to hospitals, labs, and businesses too.

- Disaster recovery – This is an incredibly useful service drones are able to offer humankind, as they have the ability to go into areas where humans cannot or should not. This is especially true after a disaster, and in fact, it may be impossible to transport water, medicine, or various other types of aid into certain areas without the help of drones.

- Military – While much of the military’s use of drones is kept ‘under the radar,’ the technology is known to be used for defense, especially in terms of surveillance and gathering of intelligence. It’s also no secret that the military has been engaged in the use of 3D printing for longer than most people realize, drawn to the technology due to the level of customization possible, and the ability to make and maintain parts in the field.

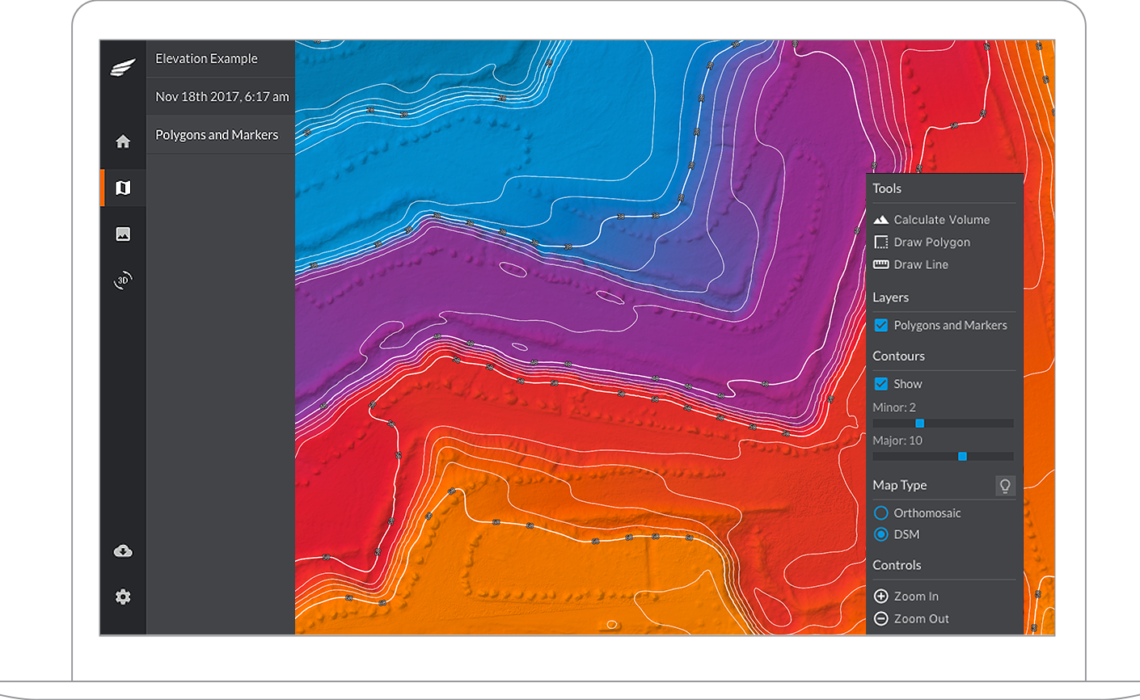

- Surveying – It’s impossible to compete with the aerial perspective afforded by drones, making them highly suited to applications requiring mapping and surveying, as well as covering large areas of land like farms that may require scanning, monitoring, and inspecting. In terms of real estate, sales and marketing efforts can be substantially expanded with features like interactive 3D showcasing of properties and of course, aerial footage.

Customization and Optimization for Industrial Applications

With the ability to bypass street traffic and cover short distances quickly while equipped with cameras, video equipment, and varying payloads, it’s obvious that drones will soon become necessary to chipping away at the endless list of tasks humans need help in completing. Undeniably useful in playing a role for taking on skyward duties within both the public and private sectors, features and functions continue to grow for drone technology, along with the advanced materials and technology used to make them.

Technology like 3D printing offers even greater opportunity and freedom in design, along with fast prototyping and turnaround of end-use parts. At Shapeways, customers rely on a variety of resources for drone applications, depending on their exact needs. Most 3D printed drones share the same two requirements initially: they must be lightweight, and they must be fast. Whether rapid prototyping or manufacturing end-use parts, Shapeways offers materials for 3D printing drones, to include:

Aluminum – Offering the strength of metal for 3D printed drone frames and parts, this material is recommended for high-performance components. Aluminum is lightweight, yet offers the toughness and durability necessary to survive air travel, as well as holding up during any unfortunate collisions while traveling.

Nylon 12 [Versatile Plastic] – Used in a wide range of industrial applications, Nylon 12 [Versatile Plastic] is known for the ability to offer flexibility for thinner structures, yet great rigidity for thicker parts. Large-scale 3D printed drone parts can be manufactured with this material via Selective Laser Sintering (SLS), whether for prototypes or end-use parts.

Multi Jet Fusion PA12 – Superior in terms of strong yet lightweight material, along with excellent mechanical properties, MJF PA12 continues to be popular for drones of all types, including those with intricate details.

Nylon 11 [PA11(SLS)] – This material offers some of the same benefits as Nylon 12 [Versatile Plastic] in terms of flexibility and suitability for interlocking parts in 3D printed drone designs; however, Nylon 11 [PA11(SLS)] is also versatile for high-performance applications like drones and aerospace overall, featuring high ductility and resistance to impact.

Depending on the type of drone, technology like Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), or Binder Jetting may be used.

Shapeways Customers Excel with 3D Printed Drone Systems

Companies like Munich-based Quantum-Systems have relied on Shapeways for 3D printed drone parts since the inception of their company which specializes in the development and production of automatic, electric vertical take-off and landing (eVTOL) fixed-wing drones. Featured as a prime example of the incredible impacts drones are making in applications like delivery and medical simultaneously, Quantum-Systems showed the exponential difference in time when their Trinity F90+ drone transported medical samples to labs. Compared to travel via courier in street traffic which could take an hour or much more, the Trinity F90+ delivered test samples in just seven minutes. These benefits could easily translate to delivery of medications and other items carried within the drone’s transport box.

Menlo Park, California-based Kespry sought out Shapeways for 3D printed drone parts due to scalability, speed, and reliability. The collaboration began before Kespry even had their first customer, and as volume has increased, the transition to 3D printing at higher volumes has been seamless. Demand quickly grew for the Kespry lightweight, autonomous drone systems, capable of surveying and mapping out hundreds of acres within just a couple of hours.

To enjoy exploration of the skies in uninterrupted, unpiloted flight, high-quality manufacturing with the ability to customize and optimize drones depending on the business solution is key. Drone technology isn’t a novelty at this point anymore, and neither is its intersection with 3D printing; what is impressive, however, is the rate at which both technologies are accelerating in terms of industrial manufacturing–and complementing one another in the process.

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways additive manufacturing solutions, and get instant quotes here.