Today we’ll be interviewing Chester Dols, the 3D modeling mastermind behind Ohne Titel’s 3D printed dress that debuted yesterday at New York Fashion Week.

Chester Dols, a graduate of the Shapeways & Eyebeam Computational Fashion Master Class, is a talented 3D modeler and designer that combines in Rhino, Grasshopper, Maya & python scripts to generate interwoven garments.

Chester Dols with his piece at Re-Making Patterns, 2015

Chester Dols with his piece at Re-Making Patterns, 2015

Earlier this year, when Shapeways was approached by Ohne Titel + Microsoft with a pitch to create 3D printed garments for their AU16 runway show, we thought to ourselves; who would be a great 3D designer fit for this project? After looking at the initial sketches, we saw stylistic and aesthetic similarities to Chester’s work, and realized he would be perfect fit for the project.

Final 3D Printed Knit Dress, Photos Courtesy of Ohne Titel

Within this blog post, we’ll learn about Chet’s journey from architecture to fashion, and what inspired him to take traditional architectural parametric design applications and re-conceptualize those approaches to design for the human body.

Close up render of Ohne Titel Dress, Photos Courtesy of Ohne Titel

Tell us a little bit about yourself: Who are you? What’s your background? Where/when did you get started 3D modeling?

I am an interdisciplinary designer currently based in Brooklyn, NY. My background and education is in architecture where I used 3D modeling to sketch and communicate my ideas.

What inspired you to begin 3D modeling?

I’m not sure which came first, the practice or the inspiration to practice, but I know that 3d modeling has become a natural part of how I think, sketch, and formulate ideas.

At what point did you learn about computational fashion? How did you find out about it, and what did you find appealing about it?

While studying architecture in college, I had a strong interest in parametric, computational design. Studio mainly focused on how computation applied to the scale of the building and the building envelop, but I was given the chance through an independent study to think about computation as it applied to the body. I ended up creating a simple algorithm over a semester which allowed me to create “tailored” clothing based on a series of measured inputs. The project, I realized later, was an exploration into the basic idea of graded patternmaking, a process used within the fashion industry to streamline sizing and clothing fit.

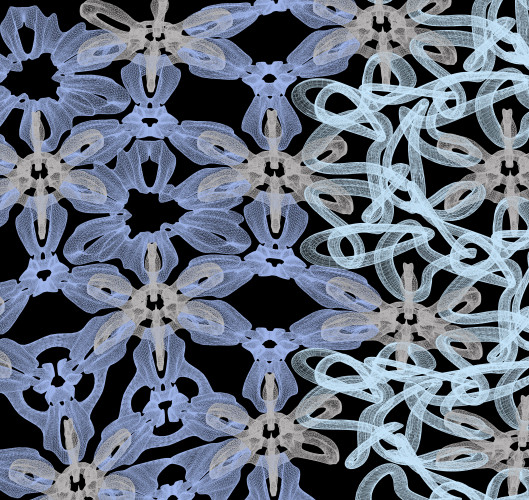

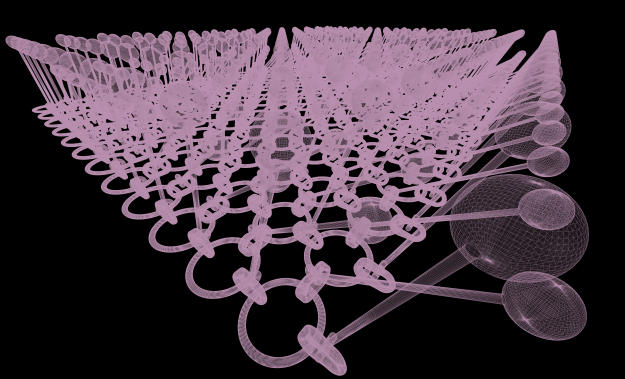

Parametric textile patterns made by Chet for our Computational Fashion Class

Parametric textile patterns made by Chet for our Computational Fashion Class

Now that you’ve worked in the “3D Printed Fashion” space for a bit, what are your opinions about field? E.g – What do you think are some of the biggest obstacles for fashion designers moving into the digital space and vice versa?

The process and methodology of fashion is so different to fields which rely heavily on 3d modeling to create and materialize their ideas. In fashion, you work with fabric, paper, pencil, scissors, and draping tape to design and produce. Furthermore, fabric isn’t like a nurb surface or polymesh, it has many physical and structural characteristics that affect its performance (ie. knits, wovens, jacquards, cotton, silk, polyester, polyblends, etc.). I’m not sure if fashion designers or the the additive manufacturing industry has more obstacles. It may be hard for a fashion designer to jump into a modeling space and create something that is printable, but I think it will be more difficult for 3d printed materials to reach the sophistication of the many different types of textiles already out there. That being said, there is so many exciting things happening right now and sooner or later I believe these industries and technologies will all converge and create really beautiful things. For me, designers and engineers experimenting with this kind of technology are the thinkers leading us into tomorrow.

How do you see this field growing in the future? Is there anything you’re looking forward to?

3d printing is still in its infancy and so is the concept of 3d printed textiles. Like I mentioned before, I’m waiting for industries, technologies, and science to converge. When we can successfully and seamlessly print with multiple materials, that is when things will get interesting. Right now, there are printers which print with two materials; take for instance Shapeways’ frosted detail plastic, which prints a wax support material and a polymer resin at the same time. But what if the second or third material isn’t a support material? If we can get 3d printers working like a loom, weaving together many materials at once to create a “polyblend” print with complex graded materiality, that’s when a new fashion will emerge.

Do you have any advice for designers looking to dive into this space?

Take inspiration from everything, and look to culture and things that already exist to make new and innovative designs. My designs look to architectural joints, knits, wovens, and chainmail and I take inspiration from both the natural and synthetic. Think beyond the form of the body, and really think like a textile designer; consider the touch, the texture, and the performance of your textile and garment.

What are some brands, designers or artists that inspire you?

Faustine Steinmetz (textile and fashion designer), Jaime Hayon (product designer), New Territories (architecture), David Altmejd (artist), Walter Van Beirendonck (fashion designer), C-Fabriek (product design), Neri Oxman (architect and thinker), Raf Simons (fashion designer), Vetements (fashion), SuperStudio (architecture), Moebius (illustrator) …. I could go on and on….

If there were zero limitations for this technology, what would you make?

Ok, so there is this scene in the 5th Element, directed by Luc Besson, where they 3d print Leeloo (Milla Jovovich) from a strand of her DNA taken from the remnants of her hand. If our technology reaches that point, where we aren’t only printing an object with one material, but objects and subjects with unlimited elements, compounds, and materials, I would totally print a puppy or puppy-cat hybrid or something. Not sure if I stand by that ethically, but you’re asking a hypothetical. Crazy thing is, researchers are already doing something similar by printing with stem cells to print functional organs.