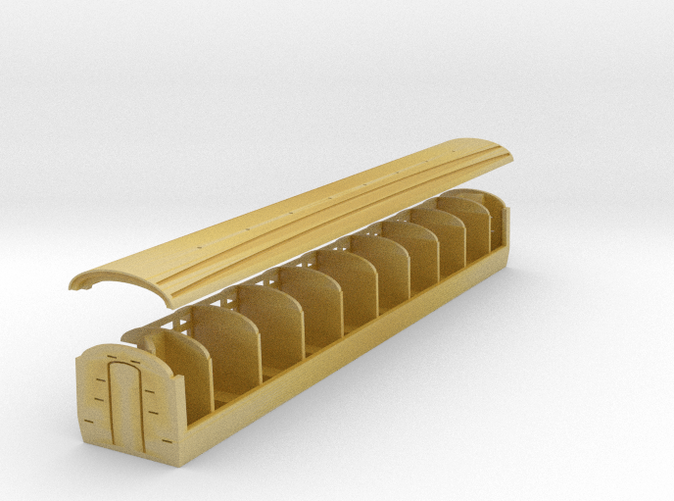

This is a British N-gauge (1:148, NOT 2mm:1ft) coach body inner, to be used with Worsley etched parts coach sides for GWR Toplight C32. The roof as printed has no projections above the elliptical profile, so if it needs smoothing, this should be straightforward; there's nothing to work around or break off by accident. There are holes to fit shell ventilators (separate model, as their detail is too fine for one of the materials I'm planning to allow for the main model. The holes are slightly angled, as they should be, and not perfectly vertical. There are also gently curved gutters for you to lie round section strip along, glue, and smooth to give a flat surface at a sensible height off the roof profile. The ends of the coach body have a trace for the corridor connection, and slots for steps to be fitted, for example cut from brass shim or thin plastic sheet. The underfloor has circular depressions on the centreline above the bogie pivot points, in case you need them as a guide. Whatever underframe you are using should provide the solebar depth and the bogie mounting points. The etched coach sides should then glue to the body sides, with window pillars lining up with the compartment divides. Fettle everything to a good fit before gluing on delicate parts. It is likely that the fit of the roof to the body will need some material removed at all points of contact first; no slack has been provided.

This model has been created on request - by someone who has now tried it out at version 28a2 (see below, and their photograph) and the main feedback was clearance for glazing, which has now been provided (version 28a3)

History:

Initial upload 2022-02-17 CAD file version 28

Offered in White Smooth Versatile Plastic - probably best for a first try, and maybe best overall too.

Smooth and Smoothest fine detail plastic - smoother surfaces, especially for the roof and ends, but more expensive.

Gray PA12 - bit of a wildcard and maybe worth a try. It is quite strong and has a textured surface which can

be rubbed smooth.

See also this model, which includes a sprue of roof vents but because if that, is only feasible in

smooth or smoothest fine detail plastic.

https://www.shapeways.com/product/2B26S2G2M/churchwardc32toplight-28-body-roof-vents

Updated upload 2022-02-21 CAD file version 28a1 with microscopically thickened (0.02mm more) centreline (x=0 or y=0) walls, to get around an evident teensy bug in Shapeways' model analyser that rejects walls on these alignments which are "exactly" 0.7mm thick for printing in versatile plastic, but accepts identically specified walls everywhere else in the same model.

Updated upload 2022-02-22 CAD file version 28a2 making all walls 0.8mm instead of 0.7mm and all 'wires' at least 0.8mm insteadof 0.7mm, and none now unsupported. Slightly adjusted the topmost end step slot position, and provided clearance for it in the adjoining internal wall.

UPDATE 2022-06-16 (version 28a3) Made clearances at the ends and the compartment divides to let the etched sides mount flush to the body when fitted with a sheet of window glazing 0.75mm thick and projecting 1.5mm beyond the furthest edge of the outermost windows. You may still need to file the compartment divides back a little bit if the glazing is thicker than that.