Our recent webinar with ZVerse, the creator of CAD as a Service (CADaaS), put a spotlight on the many innovative ways that savvy designers are optimizing innovative designs, thanks to 3D printing.

What follows are some insights into what’s possible when a partnership like Shapeways and ZVerse comes together.

1. Designing for 3D printing is no more expensive than traditional manufacturing

It’s time to debunk this common misconception. No matter whether you choose 3D printing or a traditional manufacturing methodology, there remain two main factors that determine costs: design complexity and price of materials. Traditional manufacturing methods, such as injection molding and Computer Numeric Control (CNC) machining, offer no advantages or shortcuts in the design process.

When it comes to prototyping, especially with increased speed, as well as custom designs, low-volume production and rapid turnaround for tight deadlines, 3D printing is gaining rapid momentum.

2. Specifically designing for 3D printing, however, can create certain advantages

Designers planning to 3D print their creations realize much more design freedom along with increased prototyping speed while minimizing materials usage and thus cost. To put it in layman’s terms, it’s art versus part. On one hand, designers know that parametric designs are perfect for goods that feature rigid or boxier designs where every dimension and feature is provided because fit with another component typically is part of the scenario.

In contrast, designers choosing 3D printing can work with mesh designs, which are optimal for more freeform and organic products. Popular with artists, architects, jewelers and fashionistas, designers have more opportunities to manipulate geometries and the result can be more focused on meeting unique and individual aesthetics.

According to ZVerse, digital manufacturers turn away 35% to 40% of their leads because they don’t have the needed 3D printing files, which stifles innovation. With ZVerse’s CADaaS platform, digital manufacturers can take advantage of a range of design services that directly translate into keeping more customers and revenue in their ecosystem.

This scenario extends to fix-a-file situations where an existing design file can be optimized for printability or weaknesses in existing designs can be addressed and remedied.

3. Customization reigns supreme

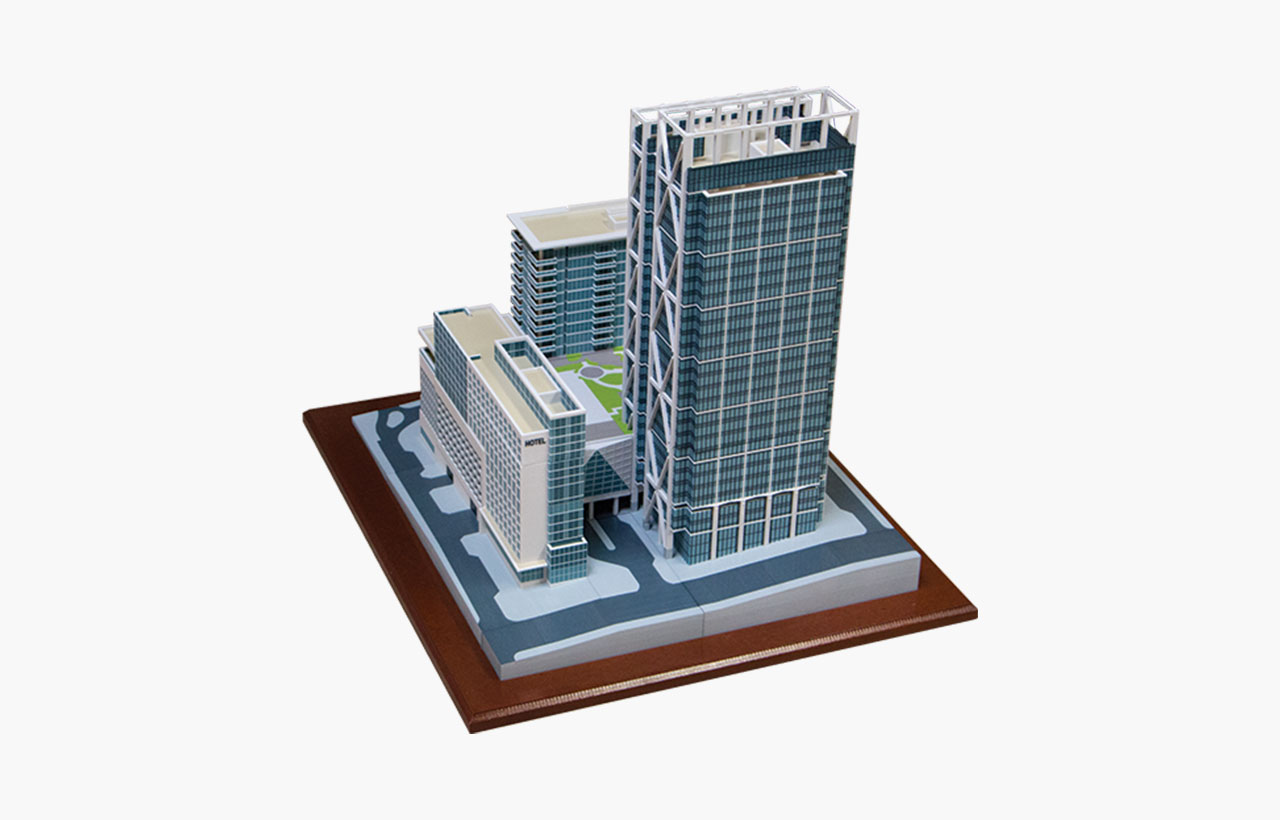

Designers at ZVerse have been asked by customers to develop plans for a wide variety of items, including custom furniture, desktop items, miniature models of skyscrapers, architectural dioramas, awards, trophies, custom urns for departed pets and even an assortment of branding irons. Shapeways has been called upon to print a custom, six-foot-long bathroom vanity that was inspired by the ocean’s coral reefs. The result had to stand up to the rigors of a family’s energetic children while being waterproof and sturdy. Several years ago, Shapeways printed a special dagger that was used on the popular TV series “Game of Thrones.”

Reverse engineering is another tool in the designer’s bailiwick. It’s ideal for parts or products made with traditional manufacturing methods that do not require exact replication. Aided by caliper measurements, pieces can be produced that otherwise may be out-of-stock, no longer available or cost prohibitive. Designers also take advantage of scanning when an exact replica is required.

By turning two-dimensional drawings into manufacturable 3D files, designers make possible results that otherwise would have been stagnated.

Designers love so-called “sticky note projects,” where a customer has an idea on paper, which are very popular at ZVerse. All a designer needs to get started is a visual reference of some kind and a description. One customer delivered four one-dimensional images and the designer took over to make the conversion needed to prepare the product for 3D printing. Producing one-off designs, which would be price prohibitive to create by traditional means due to steep start-up costs, are a sweet spot for 3D printing.

4. The jewelry industry is a designer’s 3DP wonderland

By being able to replicate the exact look and feel of traditionally cast objects, 3D printed jewelry is on the verge of achieving mainstream acceptance. According to a recent market report from Technavio, the global market for 3D printed jewelry will grow by more than $2.5B between 2021 and 2025, with a CAGR of over 22%.

A customer recently came to ZVerse with a cherished family heirloom, an antique signet ring. The task was to replicate the ring so each grandchild could have a copy. The designer made sure that every little scratch and the decades-old worn look were also part of the design. Another customer requested a custom ear cuff featuring a Roman statue. While clients typically wait months and months to receive custom-designed items from traditional jewelers, 3D printing makes it possible to drastically reduce the turnaround time while delivering truly one-of-a-kind keepsakes.

5. The growing availability of plastics, metals and colors increases design possibilities

A growing variety of versatile plastics and metals are available for 3D printing along with an ever-increasing palette of colors. While the expanding menu of choices bodes well for the industry and customers alike, all materials are different. While some are strong or solid, others are flexible, lightweight, shiny or dull. For the best results, designers must consider the ideal material for the task at hand. Choosing 3D printing with resin plastics can help achieve the really fine details while metals still are advancing and need to catch up on the capabilities.

For Shapeways customer Tilt Hydrometer, it was important that its free-floating, beer-brewing product be manufactured in different colors. Shapeways suggested Nylon 12 as the best material, using Selective Laser Sintering, and produced the product line in eight colors.

Meanwhile, 3D printing in metal is enjoying impressive growth due to the greater availability of aluminum, brass, bronze, copper, nickel, platinum, silver, stainless steel and titanium. Cost is always a consideration when making parts or products, especially from advanced materials, such as titanium, which can be cost prohibitive when using traditional manufacturing.

When investigating the best possible material, it’s important to remember that even when a material may pose increased upfront costs, the result may yield a superior finish and extended lifespan for optimal return on investment.

About Shapeways

Shapeways offers over 90 materials and finishes, and is always interested in sourcing other materials customers may be interested in using too. Contact Shapeways now to enjoy the benefits of advanced technology and materials for manufacturing creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders.Shapeways has worked with over 1 million customers in 160 countries to make over 21 million parts!Read about case studies, find out more about Shapeways solutions, and get instant quotes here.