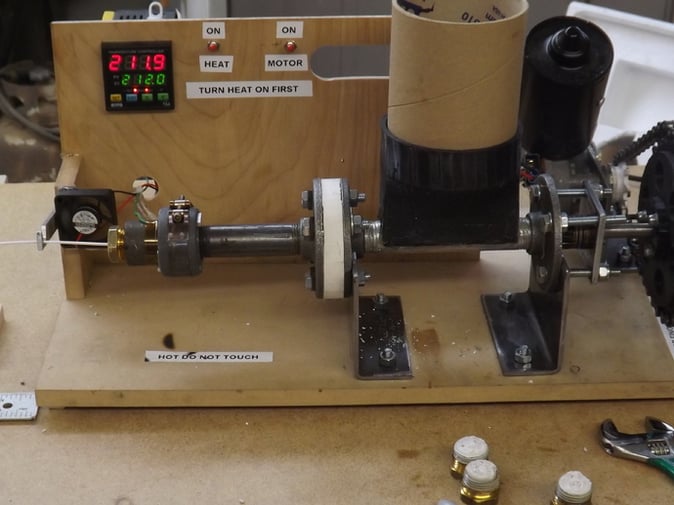

The Desktop Factory Competition launched in June 2012 challenged makers to design a cheap, open source method to turn plastic pellets (which sell for $10 kg) into filament suitable for a desktop 3D printer (that currently sells for $50 per kg). 83 Year old inventor Hugh Lyman developed the Lyman Filament Extruder II which for under $250 in parts can take standard plastic ABS pellets and squeeze them into filament.

The fact that this device is released as open source hardware means that others can modify and improve the mechanism to lower the cost and increase the efficiency, just as we have seen with the open source desktop 3D printers based on the RepRap.

Not only will this result in a massive reduction in the cost of raw 3D printing media, but it is also a very small step away from being able to grind and reuse failed 3D prints to feed into fresh new filament, or perhaps adding conductive media into the hopper to create filament suitable for making basic elctronic circuitry, or any type of tweak to customize the base material.

The speed of innovation in the open source 3D printing world is making many of the large industrial 3D printer manufacturers appear to be moving in slow motion. We are not seeing the same rate of innovation in machines nor materials and we at Shapeways would LOVE to have new materials to share, or have a way to drop the material cost by a factor of five or ten as we see made possible by innovations like the The Lyman Filament Extruder.

Congratulations to Hugh Lyman who scored a giant $40,000 cheque for his invention and the respect of thousands of makers around the world.

via Time.com

This is exactly the kind of innovation that’s needed from both high- and low-end system/material manufacturers. I just purchased a toothbrush whose handle is made from recycled yogurt cups; it’s not done via 3D printing but does demonstrate new ways of looking at old problems. In the same way, though I realize there are extra challenges to starting with a “pure” source for any kind of material reuse/recycling, it’s exciting to see ideas and progress. I like a mix of proprietary (competitive) methods and open-source opportunities.

What is the cost for an extruder and/or are there plans available/

Best regards,

Mike Dowell