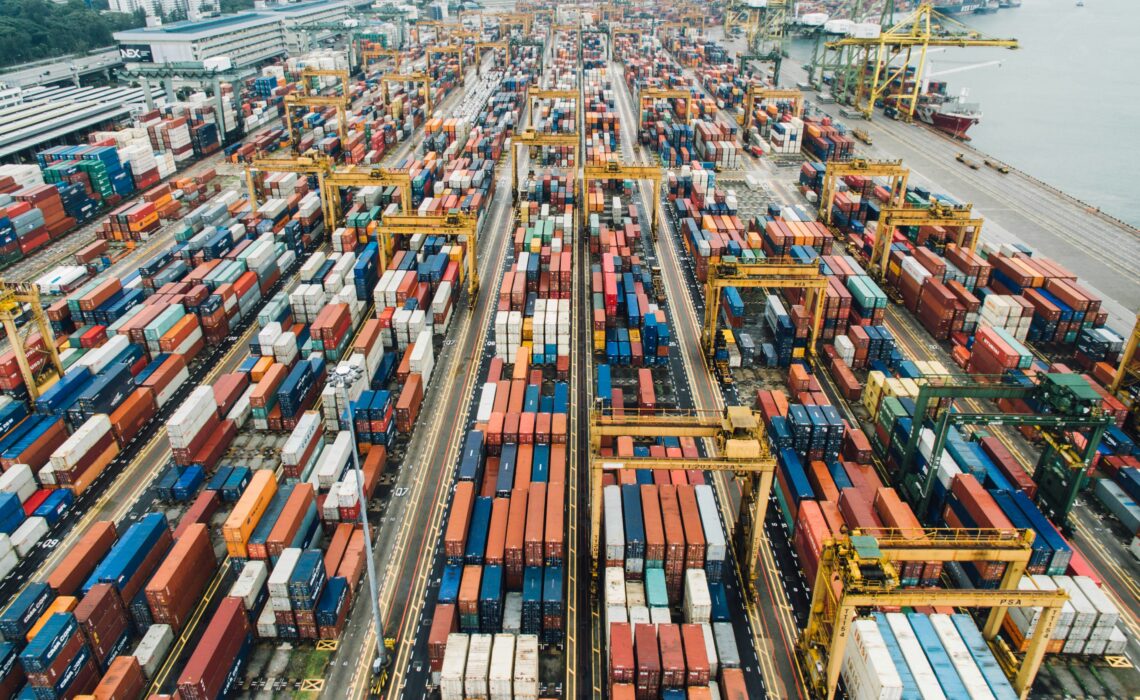

There’s nothing new about volatility in international supply chains. In the last decade we have seen a global pandemic, a ship stuck in the Suez Canal and dozens waiting to enter the port of LA, microchip shortages and war in Ukraine. 2025 has its own challenges, with geopolitical instability, market volatility and increasing uncertainty around trade and movement of goods. It is leading companies to search for alternatives for the supply of parts.

For savvy manufacturers, additive manufacturing (AM) is one of the tools at their disposal. That’s where Shapeways comes in. We custom-make hard-to-source parts with industrial additive manufacturing (AM), giving you an agile, fast, and resilient alternative — no tooling, no minimum order quantities, and no long lead times. If you’re struggling to secure critical components, we’re here to help you pivot, now .

Where traditional supply chains fall short

Global supply chains were built for scale, not speed. They work well when the world is stable, but struggle when rules change daily. They’re slow to shift, complex to manage, and vulnerable to disruption. They can handle enormous quantities of goods and materials. Scale doesn’t help when a ship blocks one of the main arteries of global trade though. It’s also useless when trying to make a business forecast over 6 months when the rules of the game change daily.

If you are sourcing low-volume parts, or keeping slow-moving SKUs in inventory ‘just in case’ you’re probably carrying too much working capital and taking on too much risk. This is where AM offers a smarter path forward — one that’s leaner, faster, and built for uncertainty – a new supply chain strategy.

Agility by design

AM offers something that traditional manufacturing and the associated supply chains can’t: flexibility. With no tooling and no minimums, you can produce only what you need, exactly when you need it.

Whether you need small volume production, bridge production or emergency production, Shapeways can be your partner. A partner that enables your business to stay in control of your supply chain, make it more resilient and if need be have the ability to immediately respond to evolving situations, something that even in the most stable times should be the goal of manufacturing organisations.

Shapeways has helped companies across industries including robotics, industrial equipment and healthcare to identify the right areas of their supply chain and transition these over to a robust AM solution. We are able to work with you to identify the SKUs and strategies that make the most sense for your line of business to be sourced with additive. For those SKUs, our solutions deliver greater flexibility, lower working capital requirements, and reduced CO2 emissions — all while quickly implementing robust solutions that deliver supply chain resilience.

Let’s reinvent your supply chain

Shapeways helps you take control of your supply chains by reviewing your SKUs and BOMs to identify strong candidates for additive manufacturing (AM). We analyze part complexity, assemblies, materials, and redesign opportunities to implement print-ready alternatives, enabling fulfillment that reduces inventory and working capital. This process helps create more resilient supply chains that aren’t at the mercy of geopolitical instability or fragile logistics networks.

The result: shorter lead times, reduced costs, lower CO2 emissions, and supply chains that can adapt quickly — without overhauling your entire operation.

Start today

While AM won’t replace entire supply chains, it can make them smarter, faster, and more stable in the areas that matter most. Shapeways brings both production capacity and deep supply chain insight, so you can start implementing meaningful change today — without disrupting your current operations.

Talk to our team today to identify which parts can move to additive to reduce your business risk, shorten lead times and cost, while secure your supply chain for the future.