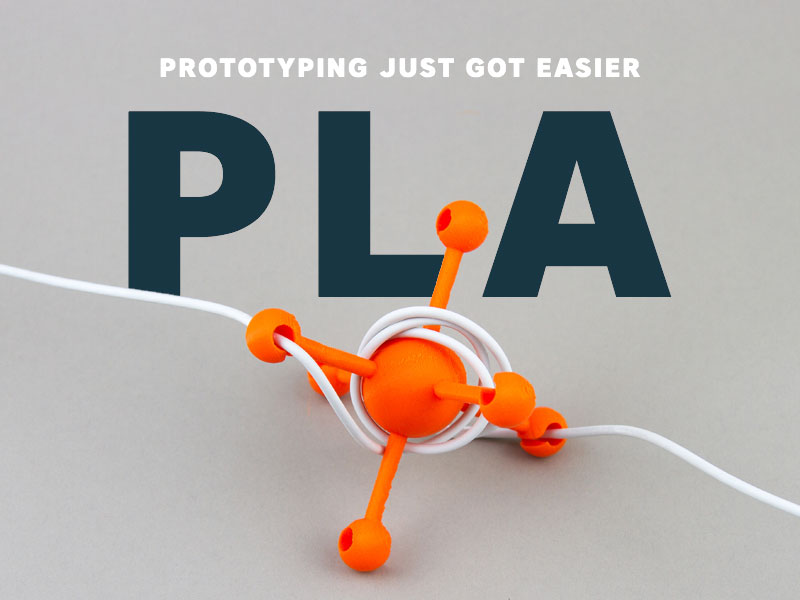

Say hello to our newest 3D printed material family, PLA.

PLA, or Polylactic Acid is a common bioplastic and one of the most popular materials designers use to prototype in FDM printers. PLA is environmentally friendly, inexpensive and best of all fast, taking 2 days to ship in the USA. For those looking for a quick turnaround time so they can iterate their designs, PLA is a great way to go. PLA comes in the following colors: Black, Orange (we were born in the Netherlands you know), White and Grey.

One of our favorite Shapeways shop owners, Susan Taing of Bhold has been using PLA printed from Ultimaker machines for years. Susan utilizes the speed of these machines to rapid prototype her designs and gather feedback on how she can make changes and improvements.

Check out some of the early prototypes that lead to her beautiful products available here.

Given that you’ve used PLA to iterate your designs for Bhold for years, can you share a little about your iterative process?

Sure, Bhold‘s iterative design process is a combination of rapid prototyping with physical beta testing that ensures the most thoughtful design. Products go through anywhere between 35 to sometimes over 100 versions before they are deemed ready for release. Each product is inspired by and solves a problem in our everyday life.

Our aim is to keep the end consumer in mind throughout the entire design process and design for maximum functionality and also the best aesthetics. The formalization of this process is our tester program Bhold Labs, the first program of its kind in both rigor and scale.

Why is it important to iterate your designs?

The reason behind the speed in prototyping is to maximize the number of exploratory concepts we can test, and with the broad base of feedback through Bhold Labs testers, we can get the most usability data with the least amount of bias. It’s a very data-driven way to design, but it’s the way I’ve found that works best to maximize impact by designing the best product for a given problem. If you’re going to invest your time and energy into such a highly engaged project as creating a product, why not do it the best way possible?

What makes FDM machines with PLA such a useful material for you iterate?

PLA is a super easy material to work with. It has a lower melting point than almost anything else you can 3D print with, so it saves both energy and time. It’s also completely non-toxic because it’s made from corn starch, which I love because I’m handling and working closely with it every day of a design cycle.

Much of your experience will have to do with the machines you use of course, which is why going through Shapeways for your PLA prints can save you the time and energy of managing and fixing machines.

What did you learn from each iteration?

Sometimes my assumptions are wrong, and the only way to know is to find out through testing. My favorite “learnings” are those that are pretty much accidental and completely spontaneous and unexpected. For example, to create a sturdier stand, we lifted up the outer rim of the prototypes for the Bheard Sound Pod acoustic speaker, but this actually had the extra benefit of improving sound quality. To me it’s addictive to design because you don’t stop learning in the process. Glad that you guys are launching PLA to enable more designers to experience this as well!

Want more details…here is how it is made and an interview with our product manager sharing why we love PLA here at Shapeways.

PLA 3D prints come from machines in a process called Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF). The machine extrudes hot filament onto a bed, building up the form layer by layer. Because of the way the material is extruded, overhanging features may need to be supported by additional support structures. These types of printers are common from schools and makerlabs to design companies and we’re excited to be providing access to this process now to everyone.

And once you have finished testing your idea in PLA, you can print it in one of 56 other materials here at Shapeways for a finished, professional look to truly show off your amazing idea!

Have questions? Ideas? Please share them with us in the comments below. You can also follow Susan’s Shapeways shop here.

Cool new material! The price per cm3 seems similar to Strong & Flexible plastic — is the main advantage the speed of production? And perhaps a more sustainable material for prototyping? Cheers!

Where is the link to the material?

hey matt you can find it here http://www.shapeways.com/materials/pla

Thanks for the article! PlA is definitely great for a variety of applications. I was reading about another material called “PETG” though. I want to know what you think about it: https://rigid.ink/blogs/news/138985991-specialist-filaments-why-you-d-use-them-and-best-printing-tips, its supposed to be odorless. Do you guys use this material?

There is no information about hardness and flexibility