The backbone of Shapeways is the 3D Printing materials we

offer to our community. From the versatile Strong and Flexible Plastics,

to the beautiful, hand-polished finish of Premium Silver, materials

inspire everyone to create new products that no one ever dreamed of

before.

Our mission at Shapeways

has always been to enable anyone to make anything they want. First, we

built a system to allow Makers to design and purchase models for

themselves. Then we created Shapeways Shops to enable anyone to launch a

business and sell their products worldwide. Now, we want to make it

easier for Makers to gain access to the newest 3D printing materials on the market and test them with us. Think about it like one big, global 3D Printing R&D team.

We’re

excited to announce the launch of our first ‘Maker Only’ material: a

flexible, rubbery plastic called Elasto Plastic! The finish, color, and

properties are not yet ready for sale to a wider audience, but it’s a perfect

material for any Maker out there who can work with a textured surface and

maybe a little extra powder arriving with their model.

The new, improved Elasto

Plastic is a great option for Makers as it is an incredibly durable

material with a lot of really interesting properties such as high impact

resistance, flexibility and compression (depending on the geometry), along with a high level of static friction because of the surface

texture. Though not strictly water-tight, it can hold liquids, but it does

not like high temperatures or fire. It is a valuable addition to our 3D Printing material options here on Shapeways that we are sure you will

find incredibly useful and fun.

To all our hackers, tinkerers, and dreamers, this is the start of a new series of materials catered just to you. The models that you submit push the limits of our machines and materials, which in turn inspire us to make improvements to meet your needs. The experiments we see posted on the forum (dyeing your own nylon or testing out surface treatments) help us understand your needs, and often get integrated into our standard processes. We want to continue to work together with our community on material innovation.

Our first Maker material is an entirely new Elasto Plastic, and is not based on based on the same technology used for our Black Elasto trial we had back in July 2012. Although it is still very experimental, this material is much more durable with more forgiving design rules. Take a look at some of our test 3D prints and the video to get a better idea how this new material will work for you.

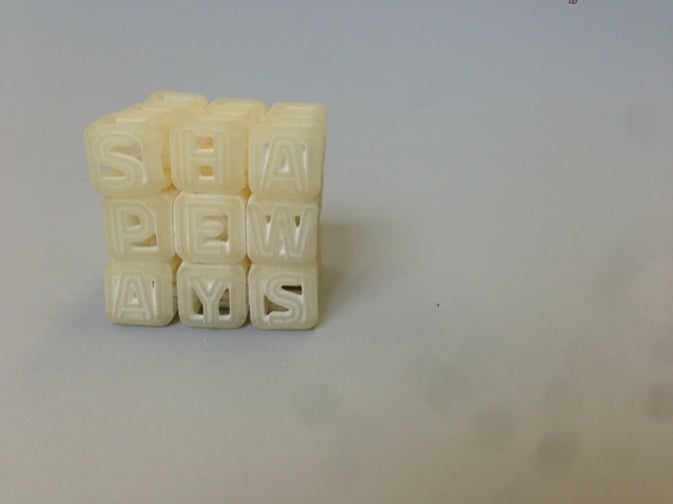

Shapeways interlocked cube showing excess powder caught in negative details.

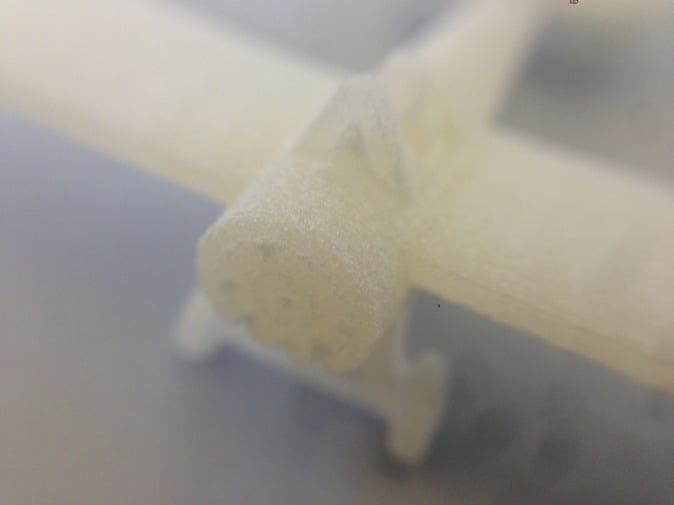

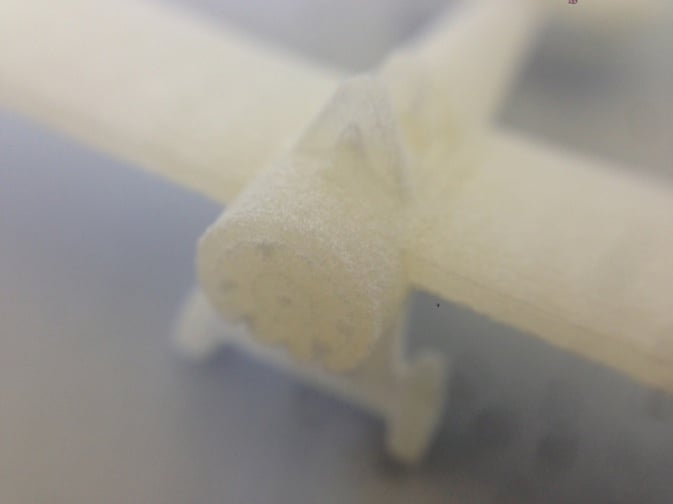

Elasto Plastic’s impact resistance makes it useful to protect your valuables.

Note some warping may occur depending on geometry of 3D model.

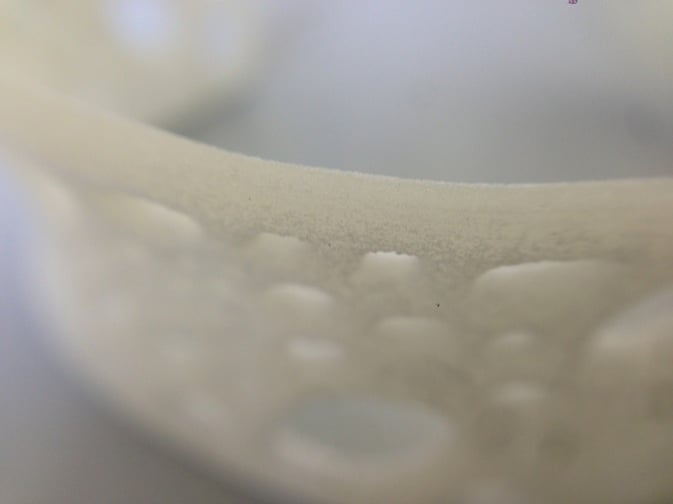

Macro shot of Elasto Plastic surface texture

Sometimes it’s squishy

Not so good for very small things.

Check out the full design rules for our 3D Printed Elasto Plastic and the video below to see how the material responds to impact, bending, twisting, stretching and fire. Remember this is an experimental material and the design rules may change.

We think this new material will redefine people’s perception of what’s possible with 3D Printing and we can’t wait to see what you make!

Hi Duann!

Great video going over the properties.

I’ll think of more questions I’m sure, but two that come to mind are, what is the scale of that aircraft in the photo? Also, what is the technical name for this polymer and or is there a MSDS for it available?

Thanks! 😀

Thanks James

We will be updating the material page with the MSDS and technical details ASAP.

Hi Duann,

Any updates on providing a datasheet and MSDS for this material? I’m specifically looking for a description of the Shore hardness and tensile strength.

Cheers.

Very cool guys! I can’t seem to select it yet (Yes, it’s my own model). Is it just taking a while to get updated or is it not ready yet? If it’s the latter, when will it be ready?

Thanks!

Hi Nate,

what is your model URL number i.e.. shapeways.com/mode/12345

Here’s one http://www.shapeways.com/model/639727/waggle-toy.html?li=productBox-search

same for:

http://www.shapeways.com/model/541355/dodeuro.htm

http://www.shapeways.com/model/572487/dodquarter.html

http://www.shapeways.com/model/541356/d12euro.html

http://www.shapeways.com/model/564333/pipe-sponge.html

http://www.shapeways.com/model/564337/inside-out.html

This has been fixed!

My apologies for the inconvenience.

It is available in the material list now. But I still cannot select it… 🙁

Thank you very much! It works perfectly now!

I don’t see in in the material list….. ???

So this “Maker Material” means we can buy, but not sell it (yet?)

If I understand correctly, this means we can see it in the enable materials list, but not actually enable it. (yet)

It does also show up in the buy your own model material list and was selectable for me.

In both lists it was at the bottom.

Then again on some models it does not show at all (yet?)

Ah OK, this makes sense. Indeed I tried to enable the material for the model (by setting the checkbox) as if I wanted to set a markup. But if the material is only available for ourselves (I mean for the makers), no need to put any markup: we can alays order in a material that is not available for sales.

“Maker Only” material… Things are obvious once you explain them… 🙂

“Our first Maker material is an entirely new Elasto Plastic, and is not based on based on the same technology used for our Black Elasto trial we had back in July 2012.”

Nice material! I remember Black Elasto was laser sintered (DuraForm Flex material). The new material looks like TPU, so how is it not based on the same technology?

This is not TPU and does not require post processing like dura form did.

Hi,

I can’t seem to to find the material available for any of my models?

How can I enable it? When I do edit model, I don’t see it in the list.

Thanks!

The database took a while to work through all models, should be good now?

it works now! Thanks Duann

This is really an interesting material. Does it bounce? Or is there a condition under which it would bounce – like if it is a certain thickness or something? Also is it or the powder on it toxic? So if a toddler got some of the powder in his mouth or eyes, what would happen? Or he swallowed either part of the material or the powder, would he be sick?

Thanks for making this demo – good info.

Hey Lora,

If you design a springy structure it may bounce, I DO NOT recommend ingesting this or any plastic powder or parts.

So maybe best to keep away from kids and pets.

You could put it in a dishwasher (on low) or washing machine to give it a good clean to ensure there is no loose powder.

Is this elasto-plastic material food safe?

also assuming no high heat, like microwave or dishwasher due to melting?

would love to know!

thanx!

Do you know the shore (hardness) rating of the material?

http://www.rubbermill.com/PDFs/tech/durometer.pdf

cheers,

c

Does the material only come in white or are there other colors available now or planned? Can you provide a reference for the white, i.e. Pantone, or RGB?

whats the minimum thickness for this material?

Hi there,

Minimum thickness for walls is 0.8mm, minimum wire 0.9mm as per material page where there are further details.

At this thickness it is not super strong and we recommend going thicker if part is under any stress.

Looking forward to seeing what you make with it.

Wow! Very useful update! 😀 Nice shapeways!

In the video, he said something about interlocking parts, but didn’t go into it. Can you explain that further?

You can print interlocking parts as long as there is a clearance of at least 2mm between components. In this way you can design and 3D print chain mail, or a fabric, essentially objects inside of objects.

Woo-hoo!! I love you Shapeways geniuses! Thanks 🙂

Great news! And also, i love that jacket! Where is it from?

Cheers

Björn

I’d also like to know

Very cool material.

How air resistant is it?

Because this material could be a perfect way to print out insert balloons used for carbon production.

Our Jack Russel is so goanna be happy with this xD

Jack Russel shoed : http://shpws.me/nZvL

That’s so cool! Please share pictures when the shoes arrive!

This looks like it’d be potentially very useful for mould making. Would there likely be any issues with pouring resin into a suitably shaped elastoplastic receptacle?

I’m wondering if it will ever be possible to print glass. Why? Because galss starts from different powders so i think that is a reday to print material, of course with right temperatures. Cheers

“Features on Elasto Plastic models may be offset from their location in the original design file – up to 30% on small models and 10% on big models.”

Can you explain this a little more, or show a photo example?

Looks awesome! Can’t wait to test it!

Have you tested any glue for connecting multiple parts? If you, can you let me know the glue/adhesive’s name?

What’s life expectancy before impereties start to change for the worst.

3D printing seems to be getting a lot of attention lately. I’m happy about that because this growing industry will no doubt have an effect on every industry involving tangible manufactured goods.

Very very cool stuff. Can’t wait to get some parts printed in this back!

Out of curiosity, have there been any tests done in dying elastoplastic parts?

I know that white SLS nylon prints tend to shed particles without the dyed coloring on the surface to act as a binding agent and was wondering if it would help with some of the issues talked about in the video.

I get the feeling that the dye would cause some problems with the elasticity of the print but am wondering if it’s been tested.

Also, black elastoprints would be awesome.

Sober mane in accordance with the power, divided into wired straightforward hair that is wired straight braids and wireless charging resolve curls forthrightly braids connected to the mains power distribute, wireless charging true trifle is via a charger that can becharging, liability the battery using the battery as a power supply.

Is this material toxic. I am curious if it could be used in a fish tank. What is the exact polymer used so that I can research it, if that answer is not known.

We will update the site with the MSDS as soon as possible.

I do not recommend use in a fish tank at this stage as there may be loose powder on some of the prints, depending on the geometry and we do not recommend inhalation through nose, mouth or gills.

Any idea on the materials UV-resistance?

Love the material and want to learn more? Check out our meetups around the world, more details here: http://shpws.me/obtz

Cheers!

News: sunglass May Have An Important role In Almost Any Website administration

I am interested in making shoes with this material. It’s the first at Shapeways that I think might work. So I would scan people’s feet and send them perfect custom shoes. I’ve read and watched the demo and have only one question. How well do you think this material would handle wear? Like walking on pavement for a year. It seems like it would do OK but just wondering if you have any intuition about it. Basically, the ideal material seems to be whatever Crocs are made of, and this seems close.

Thanks a lot!

Dan

I tried to order a part using the elasto plastic but that choice was not offered in the material selections..?