-

-

Search our Marketplace

-

- Manufacturing

- Industries

-

Materials

Not sure what material to choose? View 3D Materials Guide

- ABOUT Marketplace

- Get a Quote

- Sign In

-

15

Your Cart

-

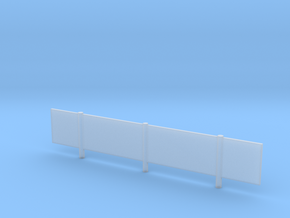

5 1/75 USN Chimney SETWhite Natural Versatile Plastic

5 1/75 USN Chimney SETWhite Natural Versatile Plastic -

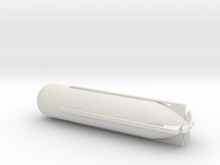

5 1/72 Scale Torpedo Mk 27White Natural Versatile Plastic

5 1/72 Scale Torpedo Mk 27White Natural Versatile Plastic -

5 Ring - Zelda's LullabyPolished Gold Steel: 10 / 61.5

5 Ring - Zelda's LullabyPolished Gold Steel: 10 / 61.5

You've earned Free Shipping!

-