While I waited for fasteners, brass rod and a new tap and die I practiced printing out figures. Figures are way more difficult to print than parts. Occlusions, undercuts, overhangs and undulating surfaces make figure models for complicated to slice. It's a compromise between orientation, printer speed, and layer thickness. This 5.25" tall Albert printed out great, after two tries, the first one failed half way through.

I finally got him oriented correctly on the table and then scaled him down to an Albert closer to the prototypes height in SE scale.

Before I started on Albert, I practices on 1:20.32 scale figures of Lincoln. These two are not as good as Shapeways, but with a little extra cleaning and sculpting, they'll do.

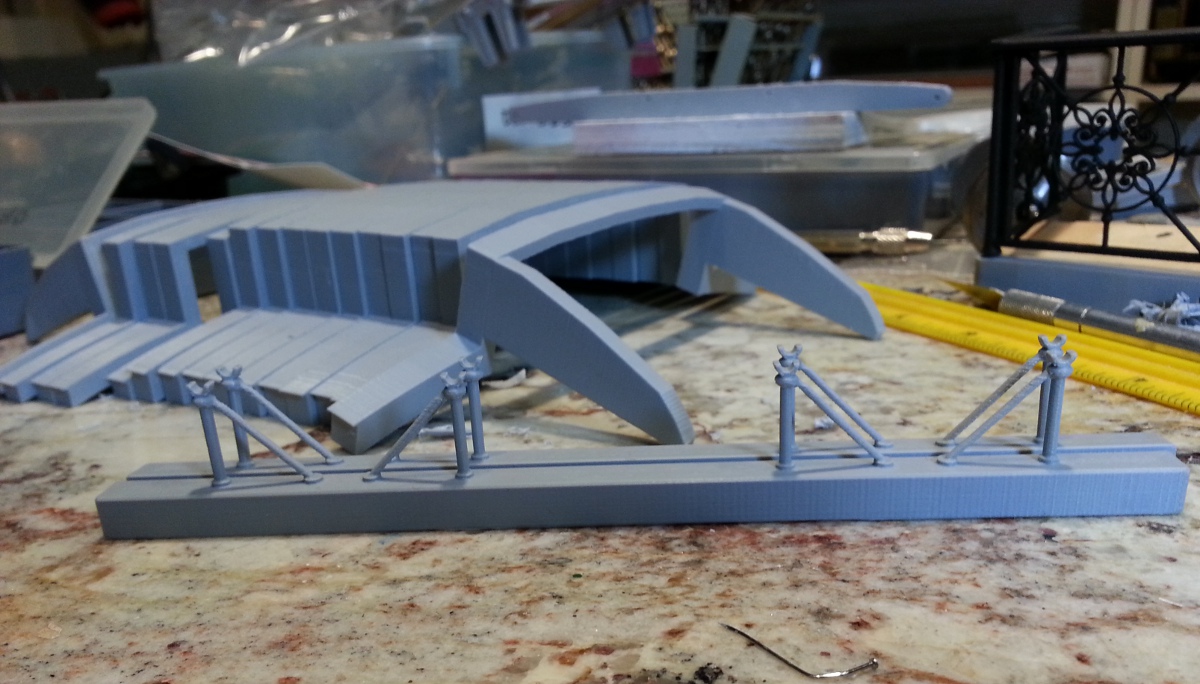

In between figures I printed up lots and lots of parts for the coach 64 build. I decided I would print as much of this model as I possibly can on my small printer. The rafters and the queen posts mounting beams in addition to windows and small brackets. When I finally got my tap and die I started assembling parts.

The dimensional tolerances on my printer are so fine, I was able to pre-drill the handrail mounting hole in the modeling application using Boolean intersects and they lined up perfectly with the hand rail I had printed at Shapeways.

The project is moving along faster with the new printer, but now I'm having problems with ADS,,, I keep going back between the coach and other projects and the rain has driven me inside where the temptation to model is greater than the temptation to print.