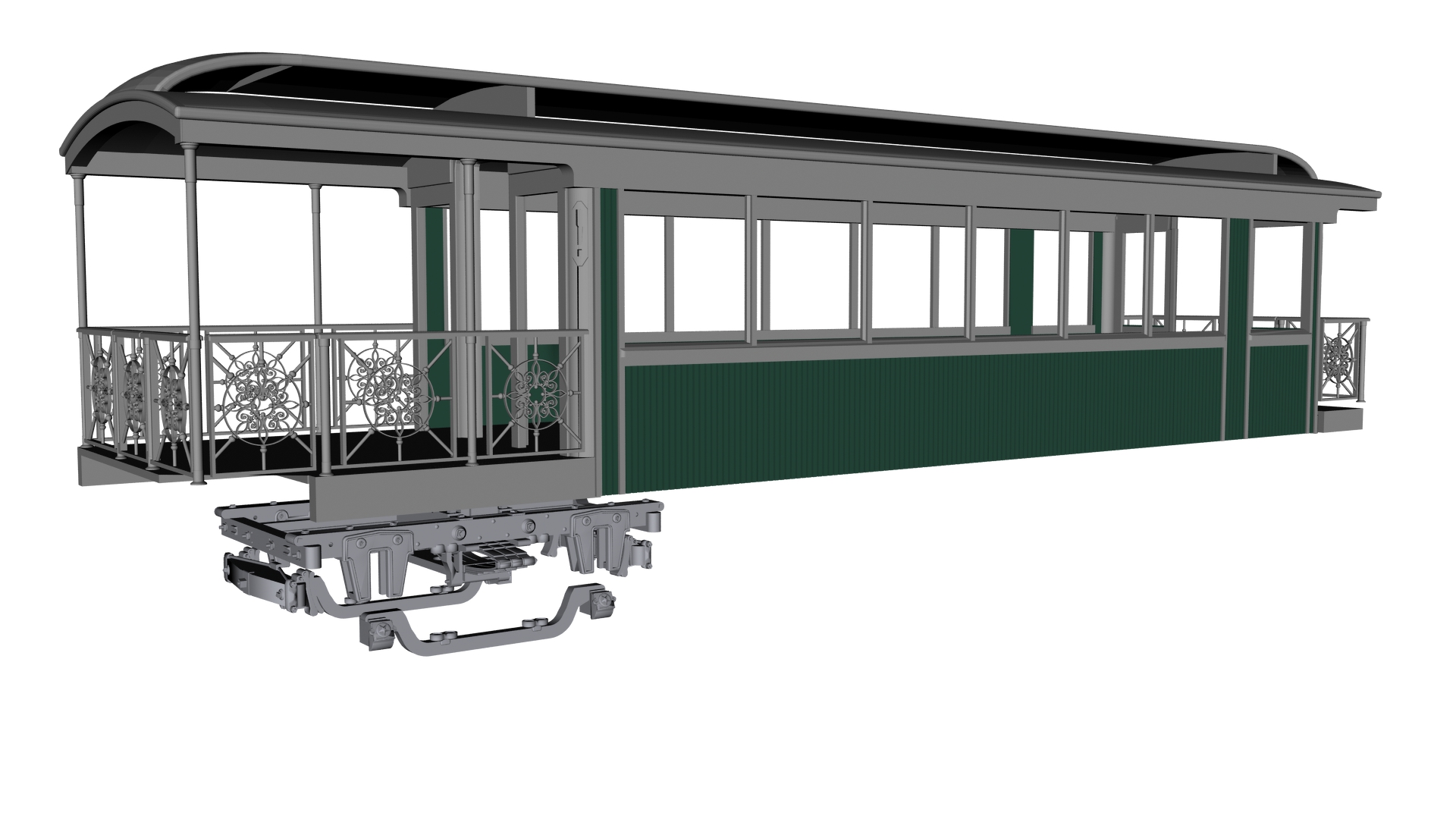

I'm creating a new thread for this project. My work on modeling coach 64 began over a decade ago.

This is as far as I've gotten to date with this wooden model. Everything on this version is scratch built using combinations of wood, brass, resin and polystyrene. That includes the trucks.

I stalled on this project mainly because of the ornate railing.

The image above is of the actual coaches front observation deck. My soldering and forming skills are just not keen enough to do this in 1:20.32 scale,,, I tried though. My failure was in the repetitive bends in the forms in the outer circles. In that scale you can't even be off .003" or nothing fits.

So as you can see from the render above, I did them in 3D which allows me to work in 1:1 scale and explode details to microscopic levels if I want. Not to mention that I can make repetitive parts and copy them over and over again.

I currently have the side frames of the trucks and the railings being printed out in WSF.

I don't think I'm going to get the detail I desire on the trucks in that material but it is a test run so that I don't waist a fortune on a higher resolution material like FXD.

I will post images of the finish prints here along with progress reports on my 3D coach build.

It would be economically ruinous to print this entire project out as the 1:20.32 scale model is 21" long, but I'm building it for the future when printing prices go down and material quality goes up. Till then I can print some of the smaller fussier parts as I need them to complete 2 scaled versions I'm doing in wood and other materials.