The actual arrangement doesn't matter much (in your case), however... You need to run a "sprue" thru all those items so that they are "connected". You've got about 60-80 separate parts there, and some of them are very likely to get lost during printing. The major point here is to construct an "assembly" that has only one part, so that it can be picked up by one hand as they pull it out of the printer.

In several of the materials, you will pay a "pre part" penalty for all 80 items, if they are separated. That minimum per part fee could run you hundreds of dollars alone. Running a sprue thru the holes turns it into a single part and will drastically lower the price. The sprue does not need to actually connect with the parts, it just needs to keep them from flying away and getting lost during the cleaning process.

Some materials don't allow interlocking parts, but most of the plastics don't have that rule, and I don't think you're going to print these in one of the metals <GRIN>

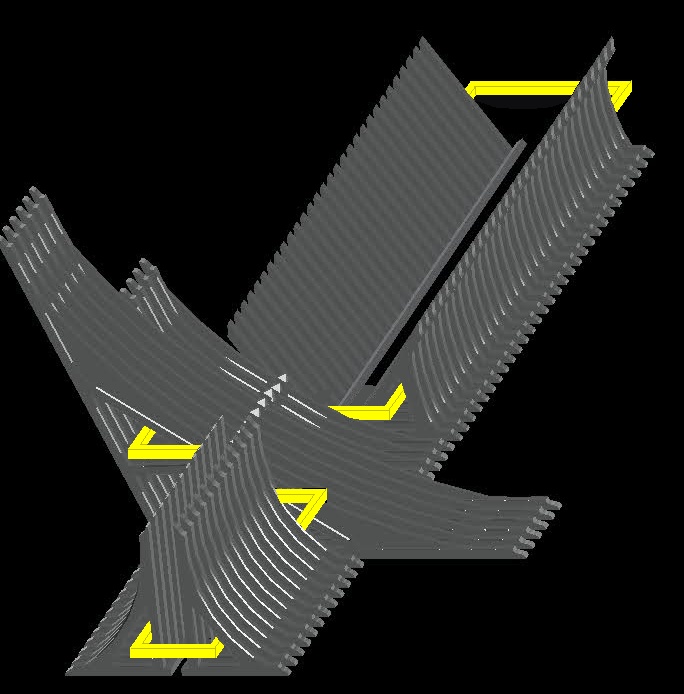

Here is one suggestion for how to connect the parts. Note: the sprues themselves are suggested to be 1mm thick at a minimum.