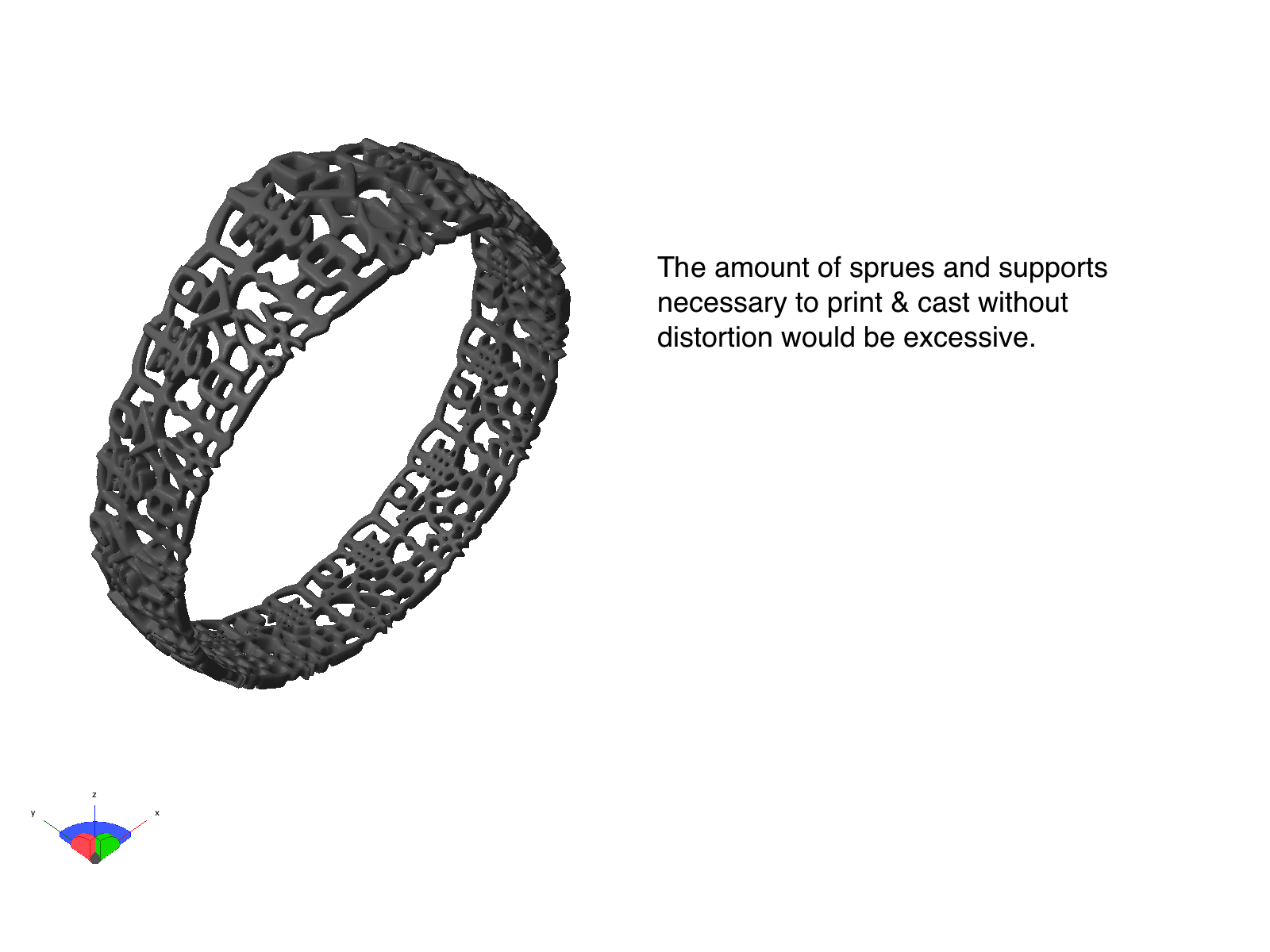

This model here

http://shpws.me/JuSY

I understood text message with rejecting, but still have some questions.

1. When all cast/support structures will need to remove, you are afraid to damage geometry in weak areas (0,7/1mm), ok. But I cannot see these places, where sprues will be removed. So, I will add material in thinnest areas and increase sides of bracelet in new revision on link. More over, I decreased number of ornamental areas and increased also overall wight of bracelet. Also I add thinkness of support structures in ornament about 20%. However, I still not sure in printability of bracelet because I got only this grey picture in rejection letter and cannot see problem areas.

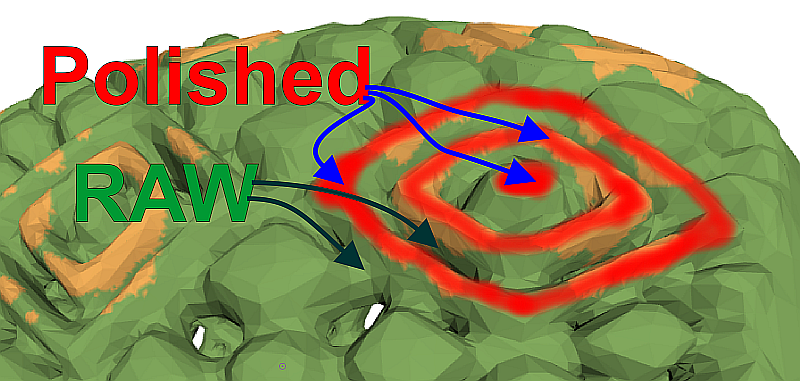

2. Most of my designs are intended for polishing only of the external (upper) parts of the main ornament. So no needs to polish side internal parts like you see below.

How I can say that this item

http://shpws.me/Jzld really printable in polished silver/etc ?...

... because it needs to be polished in some up areas only like on picture:

Most of my designs (include rejected) was REALLY printable, because they need polishing on top of main ornament, not inside or support structures. So my designs needs "hybrid" finishes - RAW + Polish. Similar structures would be beautiful in "antique silver" finishing like competitor has now.

Sincerely.