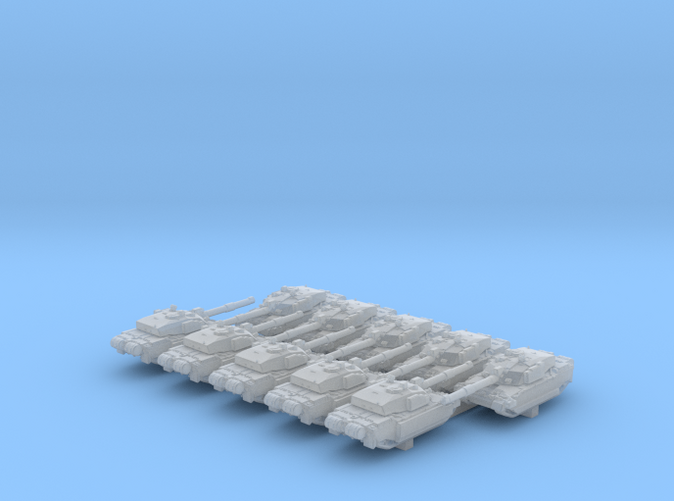

1/600 Scale Modern British Army Challenger 2 Main Battle Tank (without Cage Armour).

Contains 10 highly detailed tanks.

Contains:

- 10x Challenger 2 Main Battle Tanks (without Cage Armour)

Challenger 2 Main Battle Tank (without Cage Armour)

The

FV4034 Challenger 2 is a British

main battle tank (MBT) in service with the armies of the

United Kingdom and

Oman. It was designed and built by the British company

Vickers Defence Systems (now known as

BAE Systems Land & Armaments).

[5]

Vickers Defence Systems began to develop a successor to

Challenger 1 as a private venture in 1986. A £90 million deal for a demonstrator vehicle was finalised in January 1989. In June 1991, the Ministry of Defence placed a £520 million order for 140 vehicles, with a further 268 ordered in 1994. Production began in 1993 and the unit's tanks were delivered in July 1994, replacing the Challenger 1. The tank entered service with the British Army in 1998, with the last delivered in 2002. It is expected to remain in service until 2035. The

Royal Army of Oman ordered 18 Challenger 2s in 1993 and a further 20 tanks in November 1997.

The Challenger 2 is an extensive redesign of the Challenger 1. Although the hull and automotive components seem similar, they are of a newer design and build than those of the Challenger 1 and only around 3% of components are interchangeable.

[6] A visual recognition feature is the armoured housing for the TOGS thermal gunsight; the Challenger 2 has this above the gun barrel, the Challenger 1 has it at the right hand side of the turret. The tank's drive system provides a 550 km range, with a maximum road speed of 59 km/h.

The Challenger 2 is equipped with a 120-millimetre (4.7 in) 55-

calibre long

L30A1 tank gun,

[7] the successor to the L11 gun used on the

Chieftain and Challenger 1. Unique among

NATO main battle tank armament, the L30A1 is

rifled, because the British Army continues to place a premium on the use of

High-explosive squash head (HESH) rounds in addition to

armour-piercing fin-stabilised discarding-sabot rounds. The Challenger 2 is also armed with a

L94A1 EX-34 7.62 mm

chain gun and a 7.62 mm

L37A2 (GPMG) machine gun. Fifty eight[

citation needed] main armament rounds and 4,200 rounds of 7.62 mm ammunition are carried.

The Challenger 2 has a four-man crew. The turret and hull are protected with second generation

Chobham armour (also known as Dorchester). On one occasion, in August 2006, during the post-invasion stage of the

Iraq War, an

RPG-29 was fired at a Challenger 2 that was climbing over a ramp. The armour on its front underside hull, which was not augmented with an

explosive reactive armour package, was damaged. The tank subsequently returned to base under its own power and was quickly repaired and back on duty the following day.

[8][9] As a response to the incident, the

explosive reactive armour package was replaced with a Dorchester block and the steel underbelly lined with armour as part of the 'Streetfighter' upgrade. To date, the only time the tank has ever been seriously damaged during operations was by another Challenger 2 in a 'blue on blue' (friendly fire) incident when the damaged tank had its hatch open at the time of the incident.[

citation needed]

It has seen operational service in Bosnia, Kosovo and Iraq.

Cleaning Information

Some part cleanup will be necessary. The 3D printing process uses a waxy substance to support certain part features during the printing process. Although the parts are cleaned by Shapeways, some waxy residue may remain. It can be safely removed with water and a mild aqueous detergent like "Simple Green" using an old, soft toothbrush, Q-tips or pipe cleaners. During the printing process, liquid resin is cured by ultraviolet light. Microscopic bits of resin may remain uncured.

Let your parts sit in direct sunlight for a few hours to fully cure the resin.

Water-based acrylic paints meant for plastics is strongly recommended. Other paints, especially enamels, may not cure on Frosted Detail 3D-printed plastics.

Use dedicated model sprue cutters to remove parts to minimise the risk of damage to parts.

Please take a look at my other items.

Painting tips and preparation