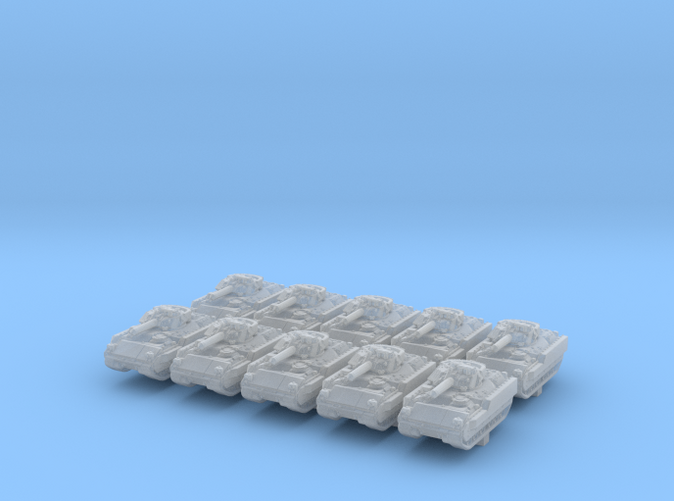

1/700 Scale Modern US M3A2 Bradley Cavalry Fighting Vehicle.

Contains 10 highly detailed tanks.

Contains:- 10x US M3A2 Bradley Cavalry Fighting Vehicles

M3A2 Bradley Cavalry Fighting Vehicle

The

M3 Bradley Cavalry Fighting Vehicle (

CFV) is an American tracked armored

reconnaissance vehicle manufactured by

BAE Systems Land and Armaments (formerly

United Defense) based on the

Bradley Fighting Vehicle family. The M3 CFV is used by heavy armored cavalry units in the

U.S. Army.The M3 Bradley CFV is very similar to the

M2 Bradley IFV (Infantry Fighting Vehicle) and is fielded with the same two-man 25mm

Bushmaster Cannon turret with a coaxial 7.62mm machine gun. It only varies from the M2 in a few subtle ways and by role. The M3 is classified as an armored reconnaissance and scout vehicle and does away with the firing ports found in the M2 series. The M3 also carries more TOW missiles as well as more ammunition for its 25mm and 7.62mm guns.

The Bradley family as a whole was originally intended to support the

M113 Armored Personnel Carrier (APC), but ended up replacing it altogether. Today, the Bradley is fielded in conjunction with the

M1 Abrams series of main battle tanks and often accompanies infantry squads into combat. In the 1991 Persian Gulf War, Bradleys and their 25mm cannon / TOW anti-tank missile combination destroyed more enemy tanks than the M1 Abrams.[

citation needed] Only three Bradleys were lost to enemy fire, however, at least 17 were lost to friendly fire. Improvements to the Bradley family have included enhanced identification features, as well as anti-tank missile countermeasures (for first generation wire-guided missiles only) and improved armor protection in the form of

ERA.

The United States and United Kingdom worked jointly on the Future Scout Cavalry System in the 1990s. The U.S. Army's intended replacement for the M3 Bradley and uparmored

Humvee reached the engineering and manufacturing development phase. It reached the engineering and manufacturing development phase before both partners terminated involvement in October 2001 to pursue other more urgent programs: the U.S.

Interim Armored Vehicle and UK

Future Rapid Effect System.

[1]

From 2003

Future Combat Systems (FCS) planned a successor to the M3 Bradley in the

XM1201 Reconnaissance and Surveillance Vehicle. That too was canceled when FCS was terminated in 2009.

The U.S. Army intended the

Ground Combat Vehicle replace the

M2 Bradley and

M113 by 2018, while the M3 Bradley could later be replaced by future variants of the GCV.

[2][3] The GCV project was cancelled in 2014.

The M3A2 incorporated enhanced armor upgrades, such as the ability to mount

explosive reactive armor, from the M2A2 Bradley. After live fire testing, seating and ammunition stowage arrangements were also changed, with the observers moved to a bench on the left side of the vehicle and the missile stowage rearranged to enhance safety. After the

Gulf War, other improvements including an eye-safe carbon dioxide laser rangefinder,

global positioning system and compass, missile countermeasure device, combat identification system, and thermal viewer for the driver were incorporated into the M3A2-ODS.

Cleaning Information

Some part cleanup will be necessary. The 3D printing process uses a waxy substance to support certain part features during the printing process. Although the parts are cleaned by Shapeways, some waxy residue may remain. It can be safely removed with water and a mild aqueous detergent like "Simple Green" using an old, soft toothbrush, Q-tips or pipe cleaners. During the printing process, liquid resin is cured by ultraviolet light. Microscopic bits of resin may remain uncured.

Let your parts sit in direct sunlight for a few hours to fully cure the resin.

Water-based acrylic paints meant for plastics is strongly recommended. Other paints, especially enamels, may not cure on Frosted Detail 3D-printed plastics.

Use dedicated model sprue cutters to remove parts to minimise the risk of damage to parts.

Please take a look at my other items.

Painting tips and preparation