-

-

Search our Marketplace

-

- Software

- Manufacturing

- Industries

-

Materials

Not sure what material to choose? View 3D Materials Guide

- ABOUT

- Investors Marketplace

- Get a Quote

-

-

0

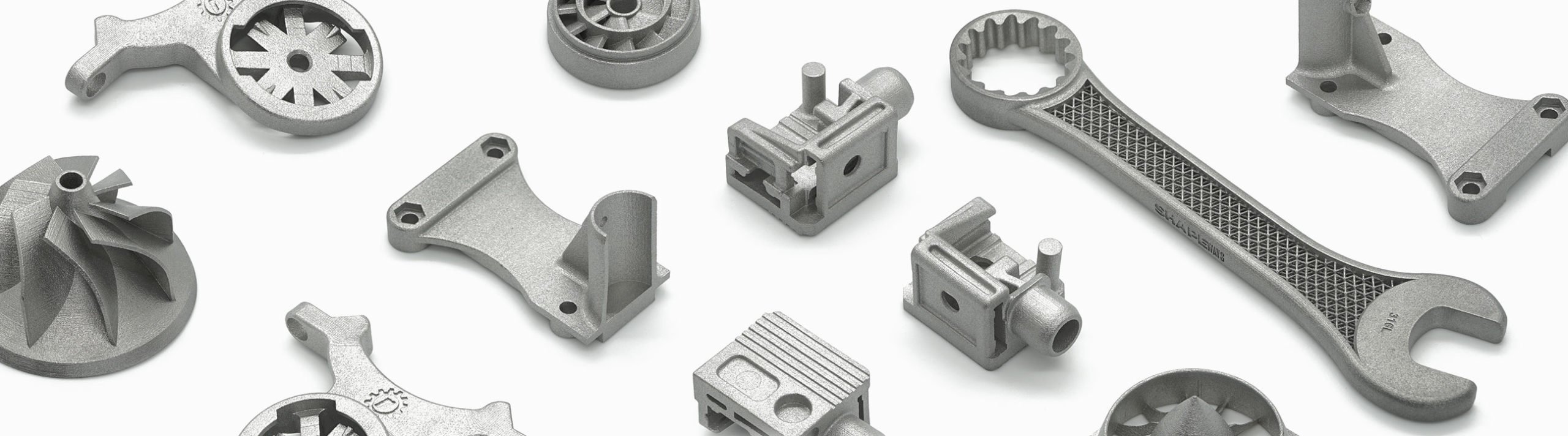

Stainless Steel 316L is popular for use in many industrial applications. It is known for its excellent corrosion resistance and superior tensile strength at higher temperatures. This material is silver in color, this material features a granular finish that can be polished.

Stainless Steel 316L is manufactured using Binder Jetting Technology (BJT) from Desktop Metal on a Shop System. Unlike our Steel offering that is infused with bronze, this material is a single alloy, 100% Stainless Steel.

Bounding Box Max

155 × 155 × 76.2 mm

Bounding Box Min

10 × 7.5 × 1.0 mm

The bounding box is a 3D imaginary outline of a box that encloses the smallest area occupied by your model. Your model must be within the minimum and maximum bounding box sizes. If the size of the model is close to the maximum bounding box, then the printing orientation will be restricted.

Interlocking

No

Enclosed

No

Max

Up to 250 parts accepted

From product development to industrial 3D manufacturing, we can help you scale your business.

contact sales