My apologies for not answering all parts of your question at once. I'm actually doing about 6 things at once right now and this has the least of my attention. hehe

A little further explanation. Yes, you can have multiple manifold meshes that intersect each other as part of a single model. this is a holistically unique feature of 3D printing. The ability to create geometry that is totally encapsulated within the printed model. Whereas this is a necessary method in some cases, it can really increase the cost of your model because it adds volume to the printed object. The pricing is based on that volume, not on 'what you can see'

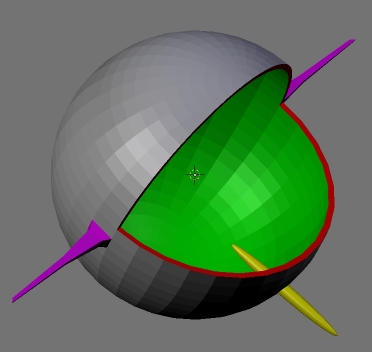

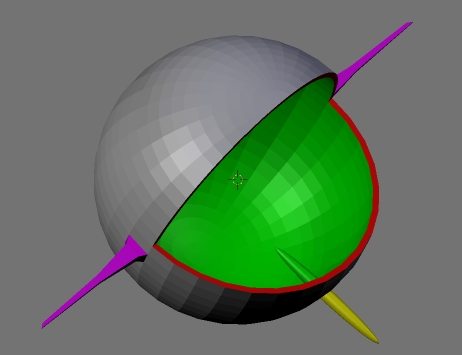

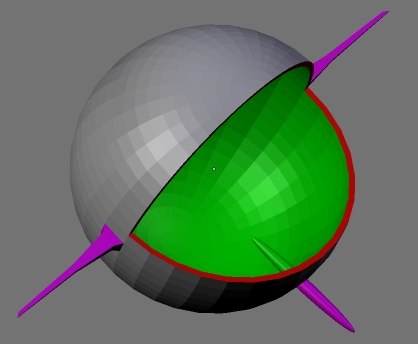

The yellow object in this illustration would be an example of a separate manifold mesh that intersects the main model.

But to a 3D printer, any portion of that separate mesh that protrude beyond the inner wall, is considered more or less as part of the inner wall. (note the green part on the inside)

and any part of the separate mesh that protrudes beyond the outter surface, would be considered part of the outter surface. I use Purple here because my example separate mesh is a solid object, so the projection would be classified as Detail, not wall thickness. If the separate mesh was hollow, the same sort of rules apply. but it gets rather complex as to what is inner and outer obviously.

it is important to understand that separate intersecting meshes add volume to the model, and volume means more printed material, and thusly, more money.