UniverseBecoming - Thanks for your question.

p { margin-bottom: 0.25cm; line-height: 120%; }a:link { }

I think layer resolution needs to be considered within the wider context of design rules.

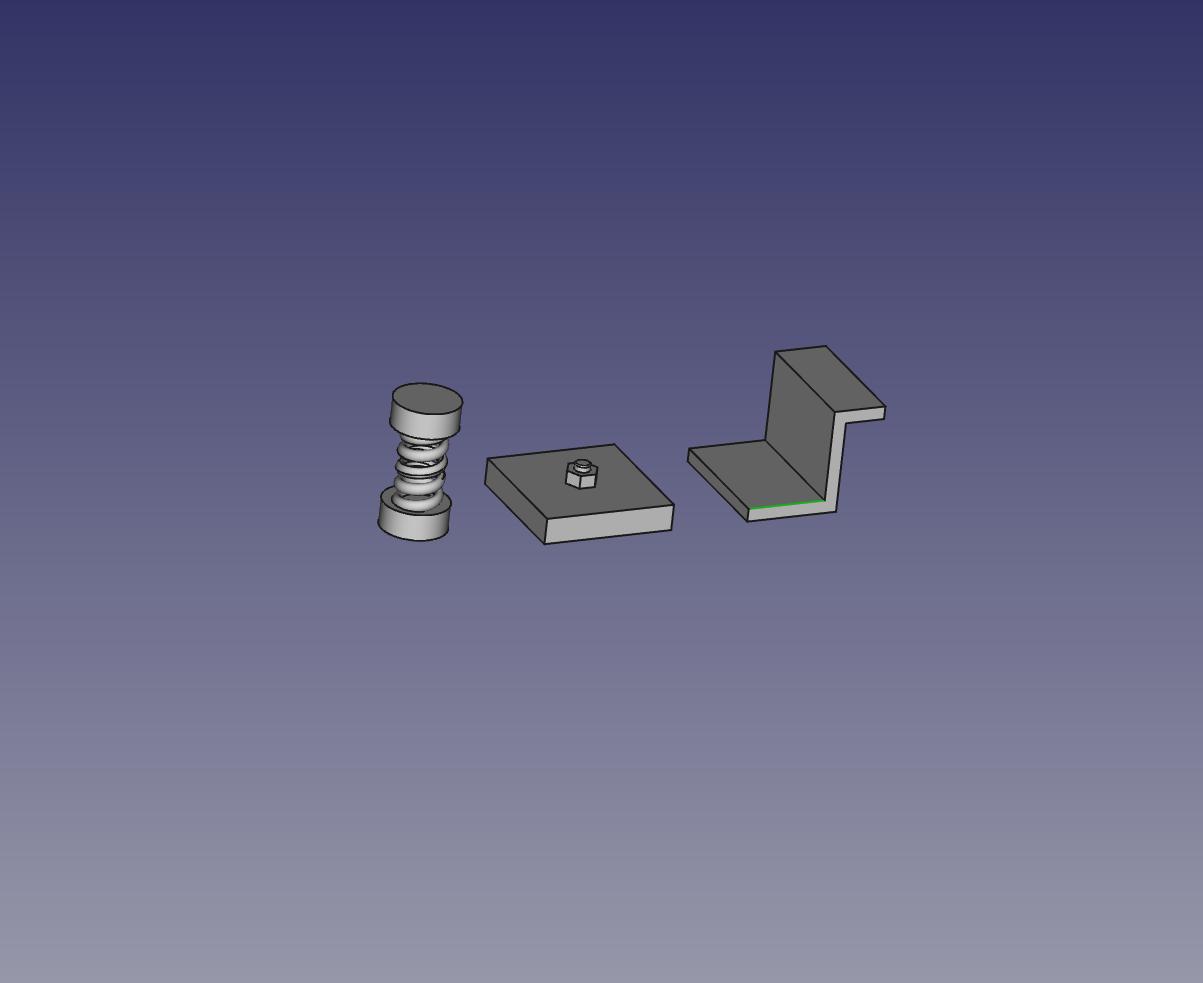

I have noticed that some shapes, even though dimensioned within the context of the SWF design rules, may fail the resolution test when converted to an stl file. The inevitable coarsening and associated tesselation can create artefacts that fall below the printer’s resolution capabilities. The coil spring in image 1 below fails with a wire diameter of 1.1mm but passes with a wire diameter of 1.15mm.

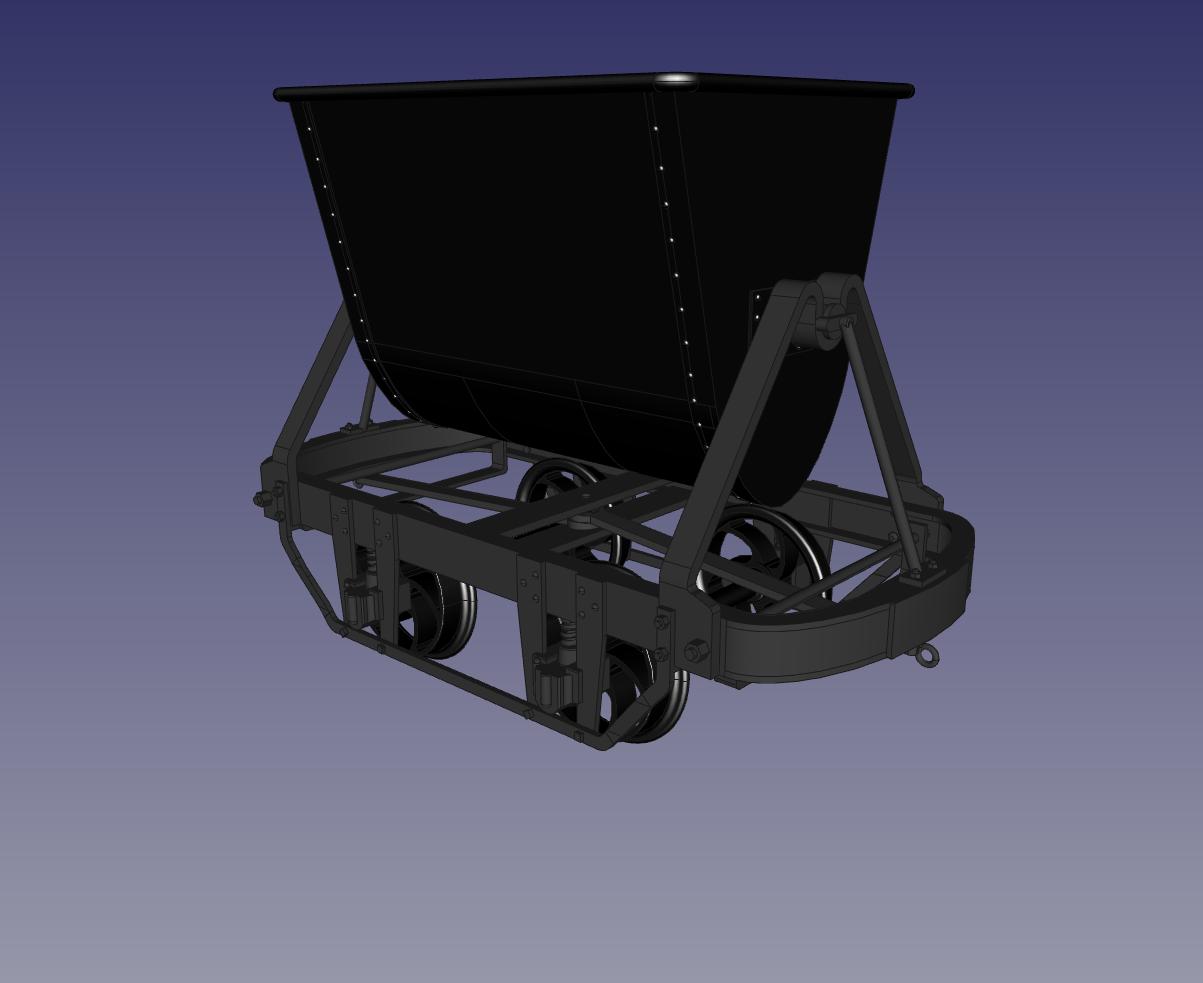

Where I think the HP-J printer will bring some resolution improvements over SWF is in surficial tolerances (i.e. “smoothness). Obviously so for planar surfaces, but also, I think, where planes join to make outside and inside corners. With SWF these meeting places usually come with a thicket of attached particles and a “saw” edge ridge. Sometimes these can be easily cleaned with a machinist’s de-burring tool, but often not. I’m looking forward to seeing an HP-J print and giving it the eye-ball test.

Image 2 shows the design for a skip wagon designed with the HP-J printer in mind. This was scaled from a photograph using the method I described here:

https://forum.freecadweb.org/viewtopic.php?f=24&t=19176 . The realism of the model can only be enhanced by the smoother finish.