3D printing continues to mature, drawing companies from many different backgrounds in traditional manufacturing to usher in a new era of technology, methods, and materials. The use of metal has only accelerated in popularity, leading as one of the hottest additive manufacturing (AM) trends. And with good reason.

Backed up by benefits like unprecedented design freedom for industrial companies, and no added lead times in tooling or machining, metal materials like Stainless Steel 17-4 PH now rule due to their sheer strength in comparison to countless other material choices currently available. Whether manufacturers are 3D printing prototypes which may span many iterations throughout product development–or high-performance parts for critical applications–metal 3D printing continues to draw the attention of industrialists for improved parts and production.

Unique Strength for Industrial Applications

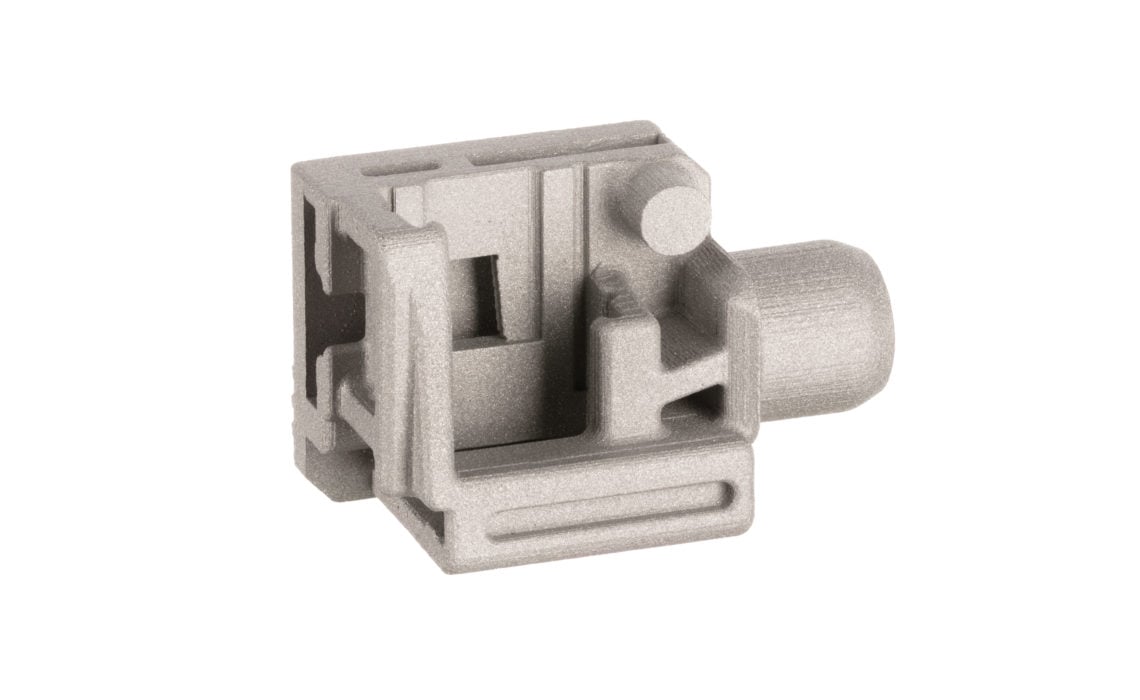

Whether Shapeways customers are on a mission to accentuate their existing, traditional offerings, or take 3D printing to a higher level, metal 3D printing with steel is undeniably faster and more powerful. Stainless Steel 17-4 PH is known foremost for toughness and corrosion resistance; however, along with offering the ability to create strong metal geometries, this metal allows for 3D printing of lightweight structures for critical components in applications like aerospace and automotive.

Like the technology of 3D printing itself, Stainless Steel 17-4 PH has evolved over several decades due to continued progress and optimization of sintered materials. This trend is only expected to grow, specifically for this metal material, but a wide range of others too. Stainless Steel 17-4 PH is also appealing due to its hardness and higher mechanical strength. It is magnetic too, which some Shapeways customers may find useful for specific applications or projects.

This material is used for a wide range of products, to include:

- Fasteners

- Jigs and fixtures

- Machine tools

- Parts for oil and gas applications

- Pump components

- Valving

Binder Jetting Technology

Offering high speed 3D printing for large-volume applications, Binder Jetting relies on adhesive for saturating the build area, layer by layer, until a desired product is complete. The metal powder not adhered with the binder is recycled during the Binder Jetting process, to maximize efficiency. Allowing for greater sustainability in manufacturing–and 3D printing specifically–this technology results in reduced waste of materials, expanded latitude in design for industrial engineers, and more options in production, ultimately, due to the wide range of other metal choices available too.

In partnership with Desktop Metal, Shapeways relies on Binder Jetting in a multi-step process, delivering industrial parts from a green part to a finished product. This 3D printing technology also allows for reduced assemblies, decreased production and turnaround time for projects, and less time spent in post-production. Due to the capability for printing with metal powders and alloys, this type of Binder Jetting manufactures prototypes and parts efficiently, offering the following benefits:

- Incredible speed in production boosts efficiency, and enhances customer satisfaction.

- Metal parts are created with precision and repeatability, every single time.

- Lack of support structures leads to freedom in design and protection of parts as the potential for damage in post-processing is eliminated.

Finishing

This material is offered in a Processed finish, with a semi-matte appearance and a rough surface. Parts are media blasted after the sintering process is complete.

Design Guidelines

For this material, 3D models must be within the following minimum and maximum bounding box sizes:

Bounding Box Min

15 × 15 × 3 mm

Bounding Box Max

127 × 127 × 76.2 mm

The bounding box is a limitation of the sintering process, and not the printer volume. If you have a part larger than the maximum bounding box–or if you are interested in additional processing of this potentially heat-treatable material for greater versatility, please contact sales for further review.

Find out more about Stainless Steel 17-4 PH design guidelines here.

Explore Other Material Options

Although additive manufacturing–with metal in particular–can be challenging, Shapeways makes it easy for other businesses to add advanced technology and materials to their lineup. This is due to the support of strong manufacturing partnerships, and a dedicated support team of 3D printing experts with extensive knowledge in 3D printing.

With over 90 materials and different finishes available, high-quality 3D printing materials are a tremendous source of pride at Shapeways. Great care is taken in choosing all resources, and each material offering is unique, bearing its own technical specifications too.

While metal 3D printers–and other printers also–can be extremely expensive, that is part of the beauty in working with Shapeways. Other manufacturers can outsource their 3D printing needs without having to invest in hundreds of thousands of dollars or more in hardware.

To get the perfect look and feel for any 3D printed part, check out the material options that Shapeways offers. Each material listed notes the available finishing options to ensure that your aesthetic parts look good, and your functional parts perform how you need them to in the end.

Upload your design and get an instant quote now!

About Shapeways

Enjoy the benefits of this advanced technology and a wide range of materials from Shapeways for 3D printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Shapeways has worked with over 1 million customers in 160 countries to 3D print over 21 million parts! Read about case studies, find out more about Shapeways solutions, and get instant quotes here.