Our team at Shapeways has worked with over one million customers in helping to bring their designs to life; however, never has that been so true—or quite as literal—upon 3D printing the latest work of famed high-tech fashion architect, Anouk Wipprecht. The Dutch designer, still heavily engaged in the realm of FashionTech (as wearables and technology converge), continues to bring a whole new meaning to getting dressed up, with help no longer necessary for getting ‘zipped up’ in the back, but rather getting everything hooked together from the scalp downward.

Reaching far into the depths of mammalian physiology, as well as neurotechnology, Wipprecht has been collaborating with the Institute for Integrated Circuits at JKU / Johannes Kepler University Linz and g.tec (a medical technology company from Austria) to create an animatronic dress that also reacts to human brain waves.

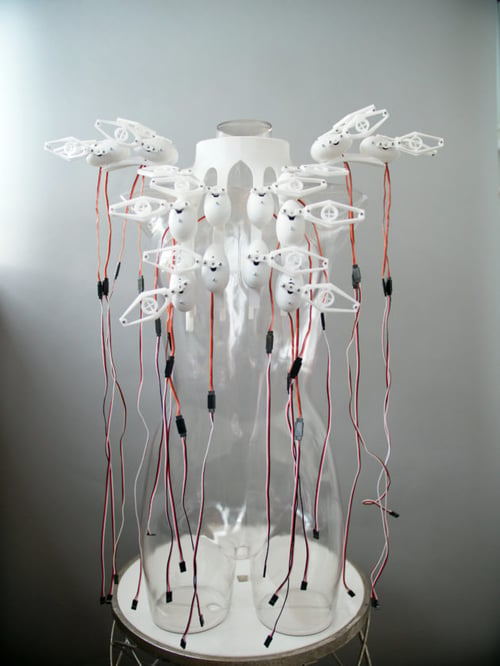

“The dress is printed out of nine parts. Together with collaborator on this project and 3D specialist Igor Knezevic from Los Angeles, we have been working on the dress and little connector parts,” explains Wipprecht.

Most of Wipprecht’s dresses (harkening back to the Spider Dress with an array of sensors, as well as the Intimacy 2.0 dress which becomes more revealing as desire increases) have been manufactured with 3D printed upper parts. For her latest dress, the visionary designer sought to create new fashion that was not only body hugging, but also suggested the complicated form of an exoskeleton with electronics ‘hosted on the 3D printed legs of the dress.’

“I worked with Anouk on several of her projects and it is always a great learning experience,” said Igor Knezevic. “The difference in this particular project is that I used Blender3D to do design and modeling of the whole piece, where in the past I usually would use 3D Studio MAX.”

“Blender evolved a lot in recent years and now has some distinctive abilities related to 3DP workflow, such as very good Boolean procedurals enabling some advanced geometries to be able to be created in one piece. But yes, in the end, the whole piece was divided in symmetrical parts to be able to fit it into printing volume.”

Ultimately, the 3D printed dress lights up in a display of brain data, surpassing novelties of the 70s like the mood ring by about 86 billion neurons. While the electroencephalogram (EEG) is usually associated with complex medical procedures meant to examine head injuries or test for serious disorders, here Wipprecht brings us to the intersection of brainwaves and glamorous garments produced via digital fabrication, culminating in what she has named the Pangolin Scales Project.

Since humans discovered the idea of covering themselves up in creative ways, fashion has been one of the most basic ways to express oneself. And while wearing fur coats may not be socially acceptable in most evolved circles today, with technology like 3D printing (and 4D printing in many cases too, with materials morphing to their environment or user requirements), designers now have unlimited options open to them for dressing everyone from svelte runway models to the average consumer looking for affordability, accessibility, and most importantly—comfort. The Pangolin dress is a far cry from normal haute couture or any type of clothing though, integrating a new spin on the EEG too, which usually consists of metal electrodes being applied to the scalp in a sterile clinical setting.

“The PA-11 + PA-12 combination and printing in Stereolithography (SLS) makes the dress both architecturally stunning I think, but also as light as possible,” says Wipprecht. “Developing this dress with 64 actuators (32 servo motors, 32 LEDs) I was a bit afraid of the final weight of the dress, but I was super excited once I integrated all the servo motors and LED’s and wires within the 3D printed mounts, that the dress has a very comfortable weight ratio—all due to the SLS technique in PA-11 / PA-12 combination.”

As the name of the project would suggest, the futuristic dress was inspired by the small animal usually found in Africa or Asia. The pangolin subsists on fare like ants and termites and many may be surprised to hear that it is also one of the most heavily trafficked mammals, exploited for its sturdy scales, body parts, and even its meat—considered a delicacy in some of the far reaches of the world. It is also considered to be critically endangered at this point.

With the ability to 3D print complex and detailed textiles, one of the greatest benefits is that no animals are endangered in creating materials that mimic the wonders of nature. Throughout the centuries, animal structures and natural designs have been behind much substantial research, as well as the development of complex materials that may later play a critical role in development of functional parts. Ultimately though, while the opportunity to delve into industrial techno-fashion obviously plays a large part in the design process, Wipprecht, JKU, and g.tec are centered around learning more about how the brain sends signals to the human body.

Science, art, technology, and fashion are fused together in a combination certainly never seen (or worn) before, with Wipprecht drawing from the inspiration of the unusual scales to create modern, mobile EEG sensors streamlined enough for human wear outside the hospital, allowing brain waves to be recorded and studied.

Wipprecht continues to reveal the magic of 3D printing, as well as the freedom—and science—of expression emerging from modern fashion. Throughout the past decade especially, new technology has allowed artists and fashion designers to work from a new, often highly industrial, medium. At first, much of the 3D printing in fashion involved flashy appliques or smaller, bulkier parts accentuating haute couture produced via conventional technology. As printing with textiles, polymers, metal, and more has continued to evolve, along with robotics, fashion designs have become much more fluid, and aesthetically pleasing to consumers. For many highly-customized pieces, sewing may not even be necessary at all.

“I like to refer to this as a ‘high-tech dress that builds up like an IKEA kit. It was much fun assembling the dress this way, using tiny M2 screws,” said the designer.

Wipprecht’s one-of-a-kind body system was recently on display at the ARS Electronica Festival, ‘a global journey mapping the world,’ held from September 9-13 in a virtual event from JKU Campus in Linz, Austria, including 120 other locations from around the globe.

From industrial components to futuristic wearables—and whether you need prototypes or functional parts 3D printed quickly—you will find an inspiring world of opportunity available at Shapeways. Enjoy the benefits of our advanced technology and wide range of materials for printing your creations with accuracy, complex detail, and no minimum or limits in terms of mass customization or single part orders. Read more case studies, find out more about our solutions, and get instant quotes here.