Your model seems to have been setup with measurements in meters.. if you pick "Meters" when you upload it, you'll have a reasonable sized object. Otherwise, you need to re-scale.

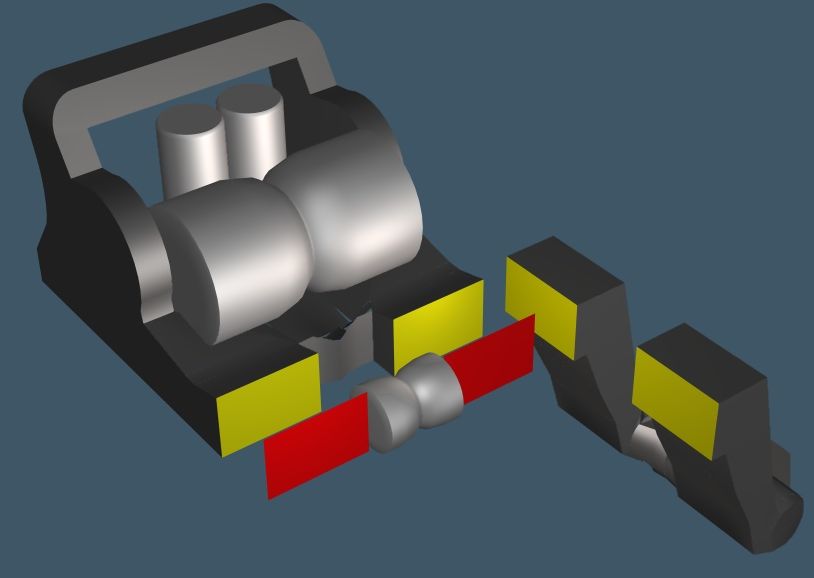

To help hilight the issues, please see attached image. I separated the shells by a bit of distance and added a bit of color to help explain.

The yellow areas are holes.. the two red areas are single-sided planes with zero thickness.

The two red shells should be removed..The holes should be filled, or you may want to union those two larger parts together

Last edited: Jun 19, 2012