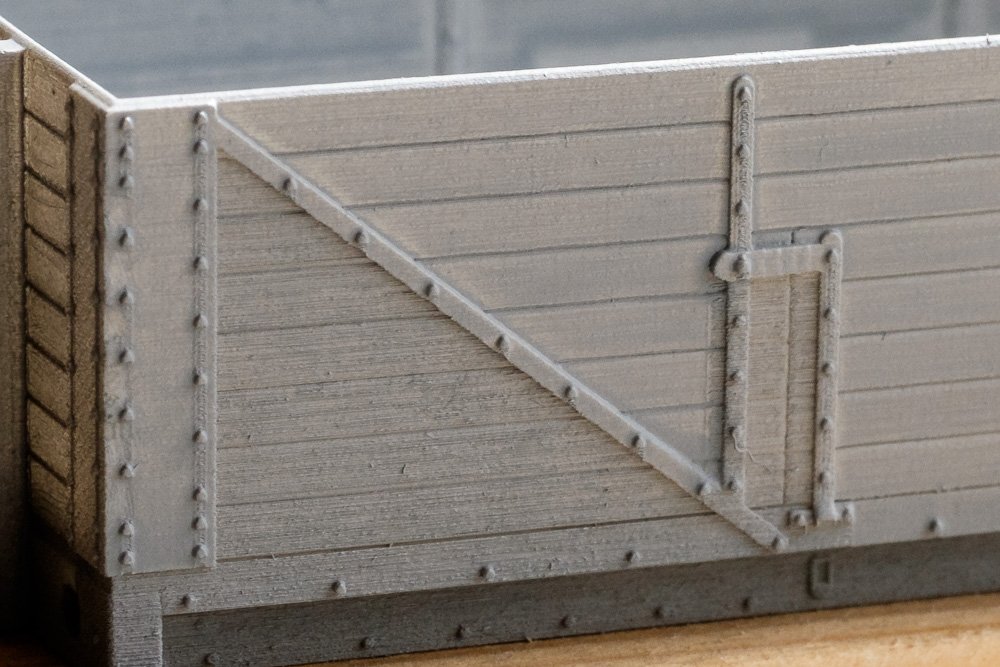

Thinking out loud here, I make a lot if railway wagons, and the layeriness on FUD is quite good at representing wood grain, but the metal corner plates with their bolt heads are not so good as there is always support material under the rivet/bolt heads and this is difficult to clean up without taking out the rivet too.

At the moment they are drawn as simple cylinders - if I was to actually dome them or cone them, would that still require a layer of support material under them? It would be a lot better for me if that was the case.

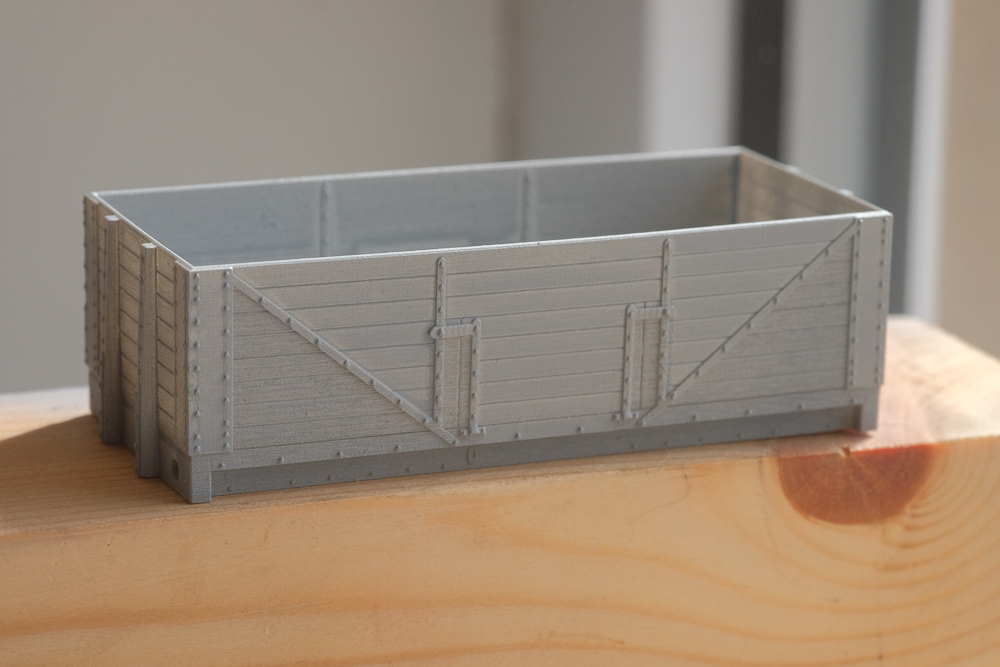

Here is my latest model, a 4mm scale open wagon:

and here is a close up of the corner plate, clearly showing the snail trail between bolt heads:

I have had success in printing models as kits of parts, which seems to result in the sides being printed flat so no support is needed for the rivets like this little wagon, but that way the corner plates can't be made without an unsightly join. (In the case of this wagon, I used separate etched brass ones to hide the join between sides and end, but that gets very expensive!