Thanks for your input on this, but this isn't a technical problem I have. I know about building the actual models and the checking for collisions etc.

The question is about the logistics of laying the separate parts out in my app and exporting as objs.

I've knocked up a quick example and some of the issues I'm wondering about:-

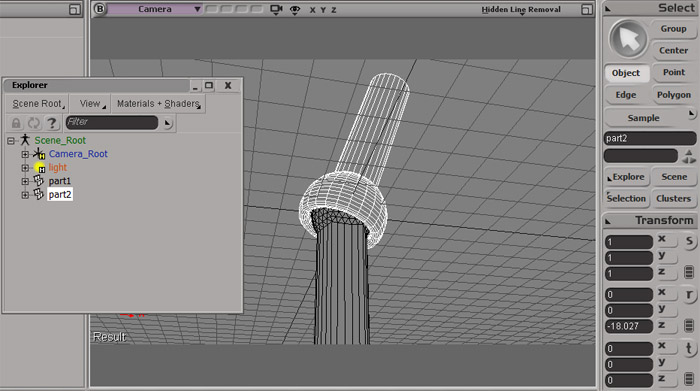

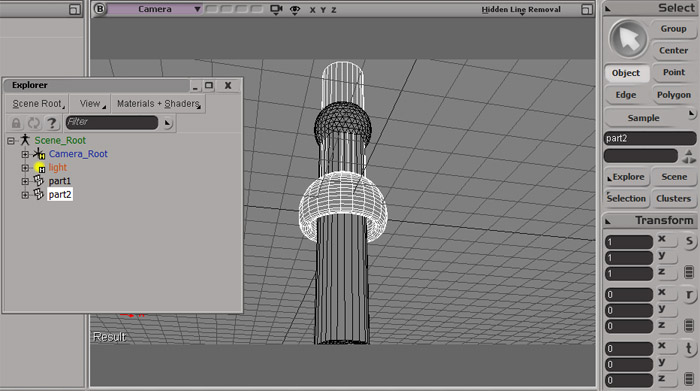

This is a hypothetical ball-joint, just to demonstrate my point. Two pieces too close to print actually in place....

So do I place both objects at the origin and export two separate .obj files?

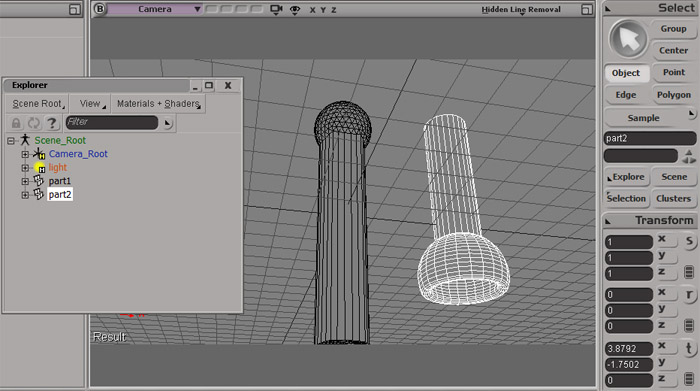

Or do I simply separate the pieces but position close to each other and export in those positions as two .objs?

The other question about that option is do you freeze the individual object transformations (translation) before exporting?

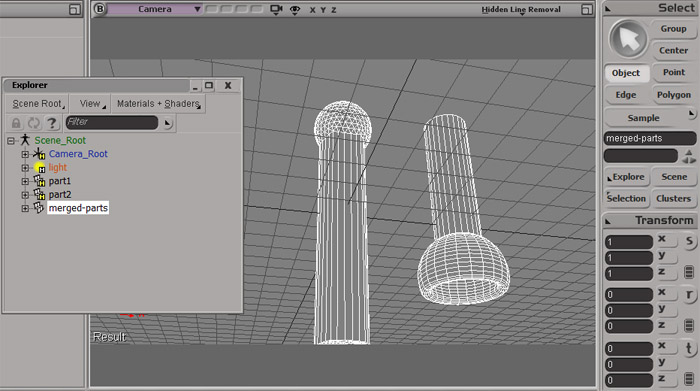

Or do I do this but merge into a single object and output that as one .obj?

Thanks

Chris