Aloha,

I'm currently working on a 3D print project involving 3 different scales; HOn3, 1:20.32 (g scale NG), and 7/8ths scale. I have already printed several parts in stainless steel for the g scale and the 7/8ths scale with success and I have printed 1 FUD HOn3 scale engine with pretty cool results though some parts were broken.

What I'm hoping to do is create 2 live steam engines which incorporate a lot of stainless steel printed parts and 1 FUD HOn3 scale model of the hole engine.

The prototype is OR&L's engine #6 Kauila. Kauila was the first loco to do a passenger run on Oahu. It was originally an engine that was commissioned by the Kingdom of Hawaii to work in the quarries. The president and founder of the OR&L railroad had ordered 3 engines slated to arrive on the Kings 50th Birthday in 1889. The engines were late, and to help the president of OR&L full fill his promise of a birthday ride for the King the King sold him Kauila which hadn't even been uncrated having arrived at the docks a week earlier.

I completed the 3D model about a month ago and textured and animated it. Here are some renders.

a short animation can be found here.

https://www.youtube.com/watch?v=ViXwW9Nd_Yg

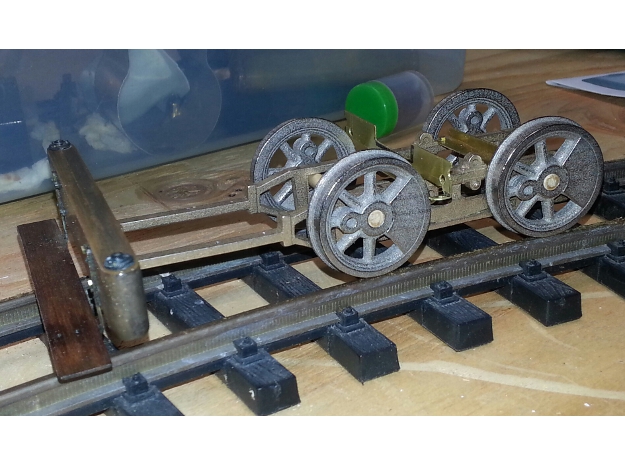

While I have the frames, drivers and rods for both the g scale and 7/8ths scales model so far I have been focusing on the 1:20 scale model. Here is an image of the 1:20 scale models progress so far. Only the wheels and the chassis are printed. The rods are not installed yet as I still need to fabricate and mount the journals.

You can follow this build at

https://forums.mylargescale.com/18-live-steam/42906-erection- drawings-0-4-2-t.html

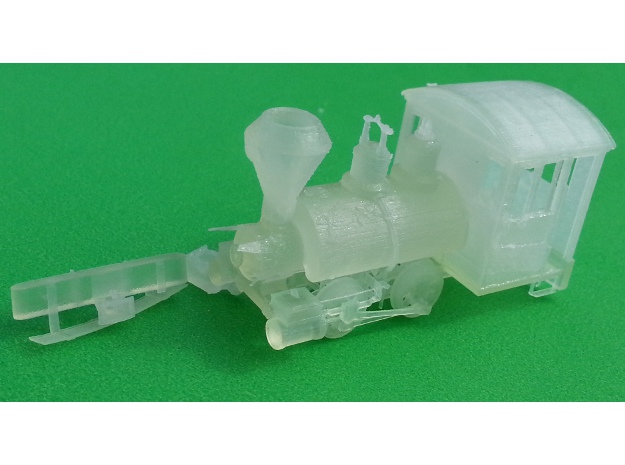

I have also test printed the HOn3 version. Here is an image of it.

I have corrected some of the weak areas of the model and I am currently printing another model out to see if I can keep the front beam on as well as recover some of the back-head detail that is missing from this one. To tell the truth I was surprised it printed at all.

The HOn3 version of this engine as well as all the stainless steel parts are available on my shop

https://www.shapeways.com/shops/ScaleHumans

I am currently converting some more parts for printing in Stainless steel. The include (so far):

The Johnson bar and assembly

The reversing lever

The valve timing cranks

The tops and saddles of the domes

The rear coupler

And the front coupler

I am also printing some of the other parts to use as templates to fabricate the other parts from brass stock.