I'm working in WSF and having some issues understanding when a hole will be preserved.

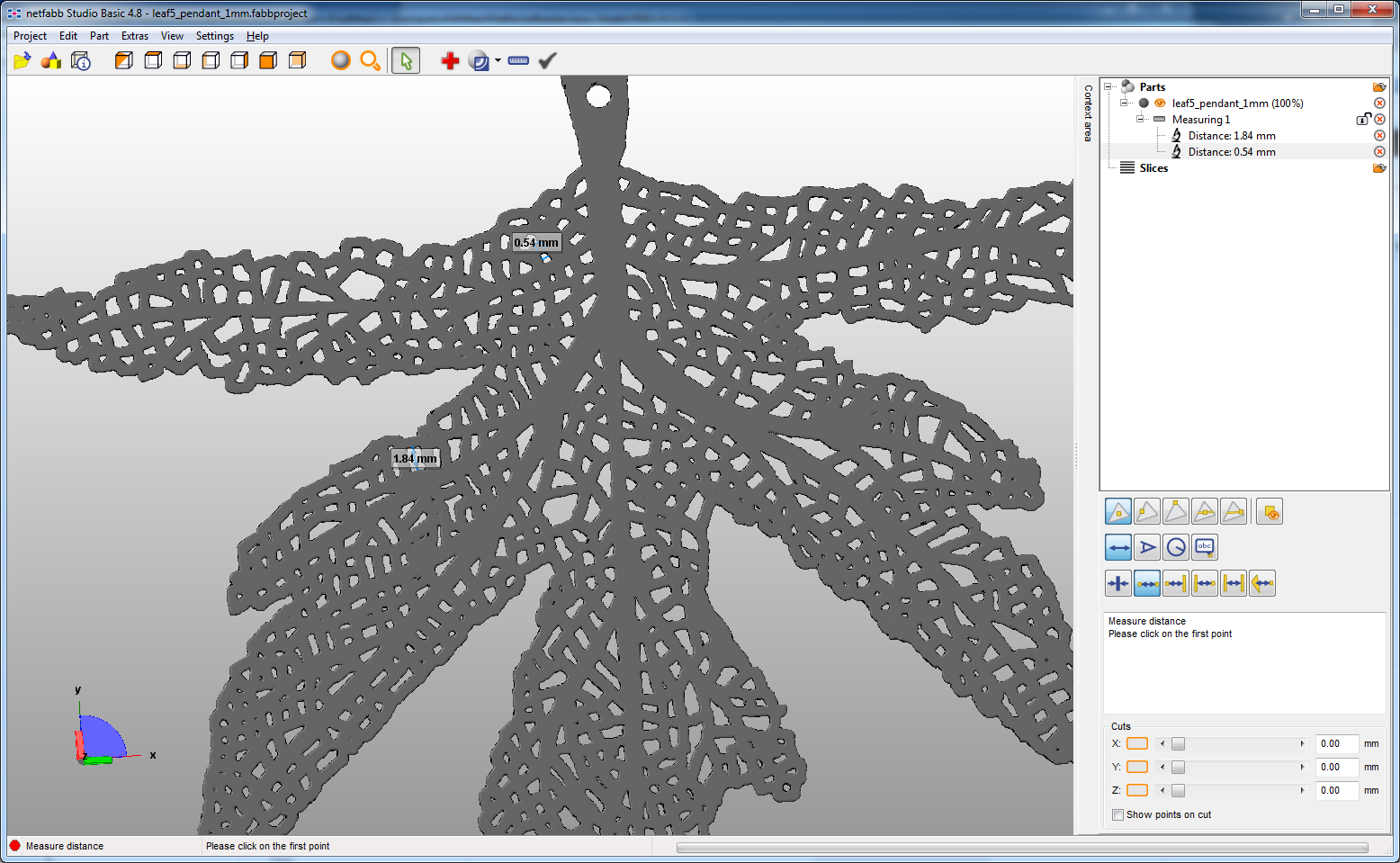

I have the following design:

My hope was most of the holes would be preserved. It seems like most where not. Is there a guideline for how small a hole can be. I can't find one on the material page. I feel like it used to be there.

it feels like the powder could not be removed from the holes. I made this 1mm thick so perhaps it would have broken if the depowder air was really forced onto it.

If I make this part thicker do you think it can be better cleaned(if that is the problem)? Or do I really just need to make the holes larger?

Originally the holes where larger but then the wallthickness was below 0.7mm. I tried to respect that more by thickening the lines but I'm not really happy with the final outcome. A lot of the holes are 0.5mm square or greater, they have an indent but don't go all the way through.

I'll put a picture of the 3d printed object next message.