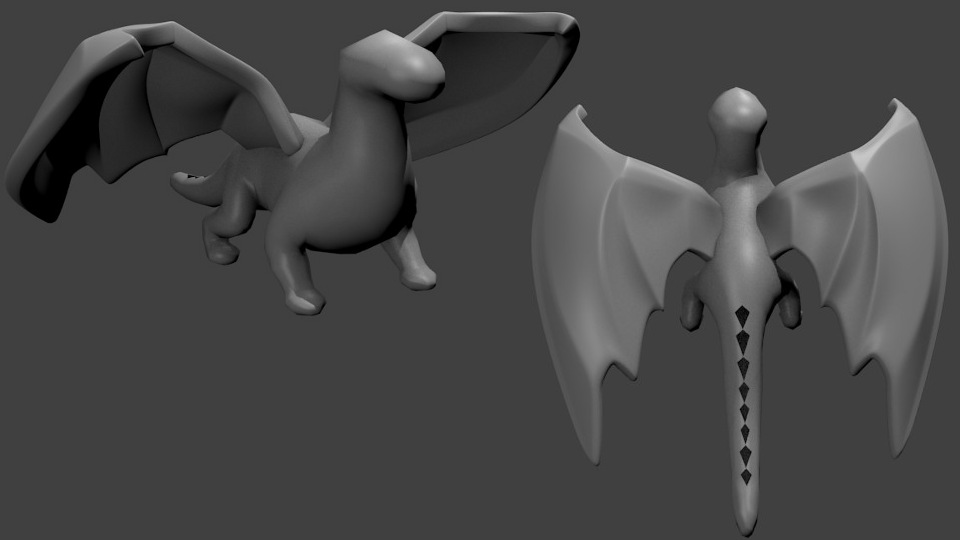

This is still the early stages of the project, but with a basic topology for the body and the wings, I'm considering the aspects of the end result. Specifically, I want to print this in metal. Obviously, I can't skim the design rules on this one, so the wings will definitely be 3mm thick, and I'll have to make sure they thicken where they meet the body.

The part I'm not sure about is the hollowing. I seem to recall that metal pieces beyond a certain thickness need to be hollow (due to uneven cooling between inside and outside). The body is ~13-15 mm thick at present. However, I don't want to have a big obvious hole in the bottom. So, here are the questions:

1. Do I have to make a single hole through which all the stainless powder from inside can be drained easily? Does it have to be hollow at all?

2. Would several small gaps along the underbelly (hopefully hidden by the armor plates) be sufficient?

3. Does anyone have creative suggestions for subtle holes?

EDIT: Apparently, the design rules no longer say that models with large volume have to be hollow. I seem to recall a maximum thickness defined (10mm?), but maybe that was just ceramic.