Unfortunately this project has been cancelled due to unforeseen circumstances

Hi Guys,

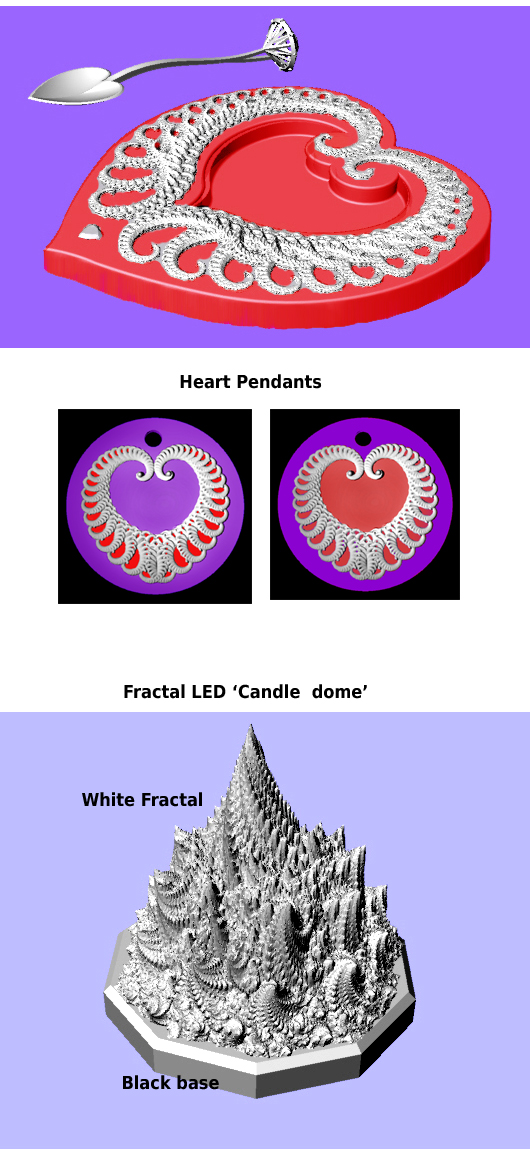

Over the last 3 weeks or so I have been creating some designs to be 3D printed in plastic (white strong and flexible polished, and for smaller items Frosted Ultra Detail), with a view to having molds made of them for production in fine porcelain. Some pieces are designed for Jasperware and some sculptural forms too.

I am just waiting on a couple of Shapeways prints to arrive so I can be sure that the level of detail and finish are going to be suitable for molding for super smooth fine porcelain.

1.FUD should be good for jewellery sized objects, and the small plate design below. FUD will also achieve the delicate detail that porcelain can achieve (there is almost no minimum thickness for porcelain - extremely lacelike details can be produced)

2. I am hoping that WSF polished will suit a fractal lithophane/ LED candle holder.

3. Id love to create something lamp sized but WSF polished is only available up to a maximum bounding box of 150x150x150 mm, and FUD is going to be out of my current budget for very large objects.

So does anyone have suggestions on how to smooth large models in White Strong and Flexible? (complex shapes so I cant just sand it etc)

Below are some images of designs that I had intended to produce in fine porcelain. The porcelain manufacturer George Engel (Phoenix Rising Ceramics), provided colour suggestions by emailing me several roughly (photoshopped) variations of my original designs (some shown below).

Janelle