Andrew, thanks for posting this!

I would, very much, appreciate having control over the print orientation of my parts. I used various forms of 3D printing as it evolved over the last 25 years in my professional life, so I have a very good understanding of the impact orientation makes on print quality. With retirement, I'm stepping my use of the technology up considerably.

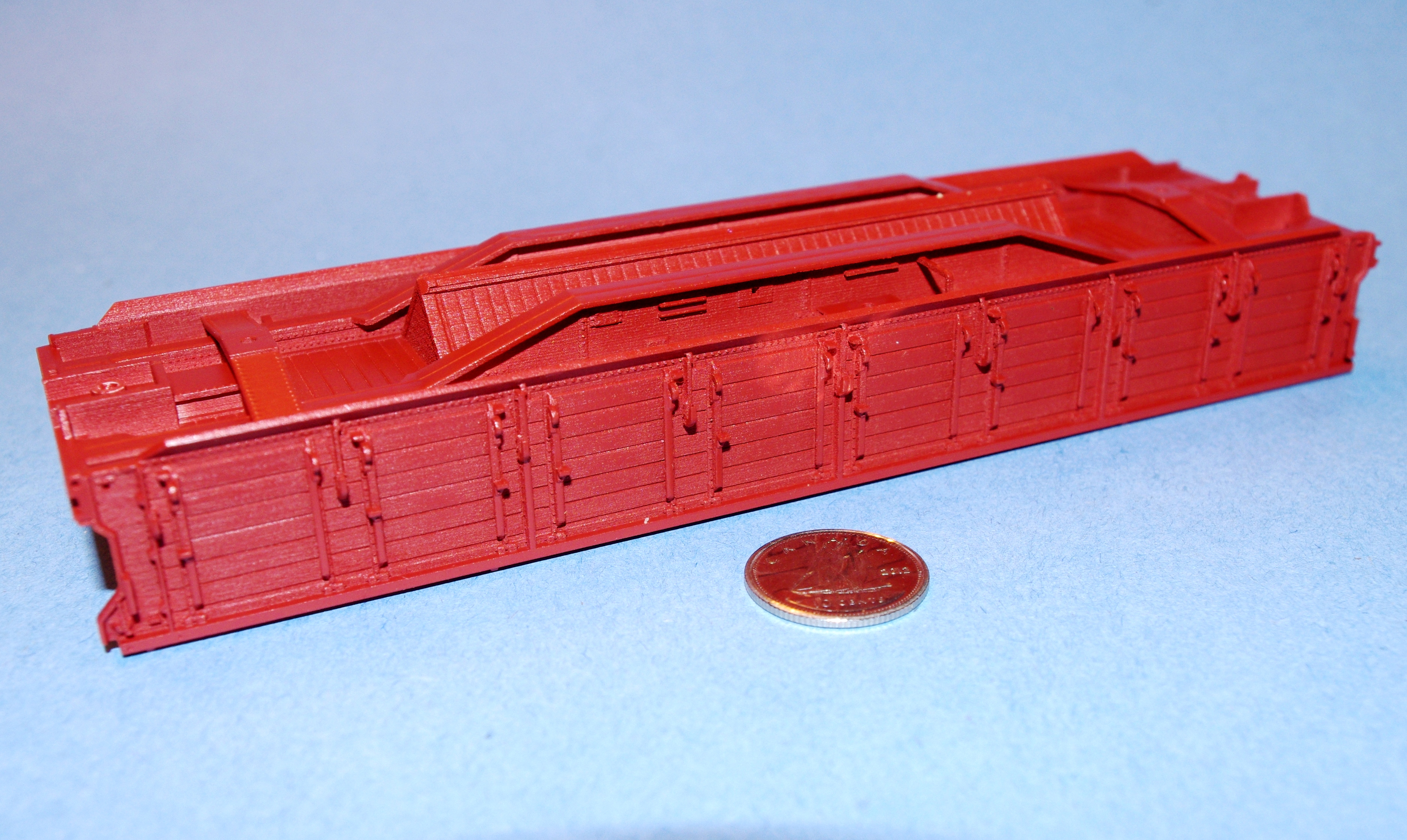

I design model railroad parts and equipment. Quite a bit of this stuff is older equipment partially built from wood. The printer grain can actually help with some of these things... see my recent FXD print of my HO scale CNR Hart Convertible Gondola. In this, with "bathtub" orientation, it gives a nice wood grain effect.

In other models, the boards run vertically, and bathtub print orientation works against me. Still other models are of all- steel prototypes. and it would be best to have these smooth surfaces facing up.

As long as a designer understands what factors are influenced by print orientation, this can give huge benefits in consistent good quality. I was used to specifying print direction at work, both for our own SLS printer and for outside agencies. It was a real shock to my system when I realized SW doesn't accommodate this!

I absolutely agree with Stony, that people will need some sort of guidance to understand how to choose print orientation. I learned on the job, as the technology developed, while just about everybody else was learning the same thing... but now we have artists and hobbyists becoming involved in printing, not just engineering types. These folks definitely need some sort of reference material to help them make good choices.

A "no preference" button could make the choice easy for novices- this would allow the SW people to use their judgement. Perhaps the choice might not be ideal, but neither is the scenario where a novice makes the wrong choice.

My designs are almost exclusively FUD or FXD. I only use WSF when making structural components that can either be easily cleaned up or that will be hidden, or when forced to use it due to model size. So far, I haven't seen the need to use any of the other materials.

Steve Hunter