Hello

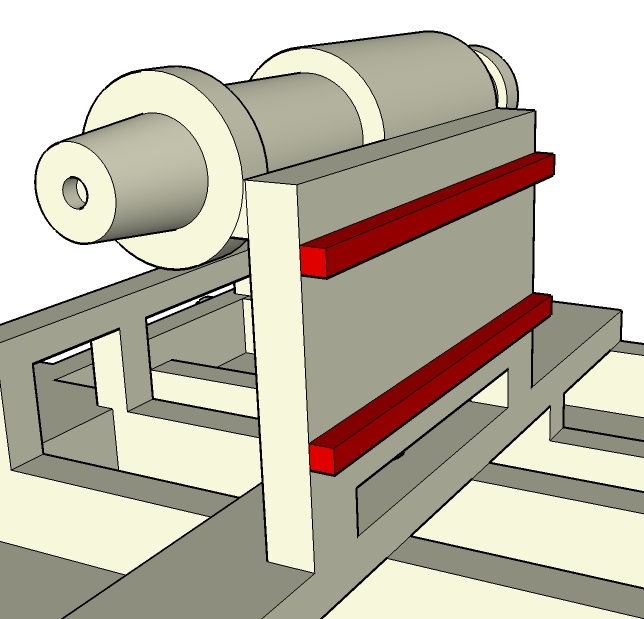

I'm having trouble with the customer service team in New York (I think) and their interpretation of the design guidelines about when a surface detail becomes a wall. This is the offending model, the problem parts are in red.

They are 0.5x0.5x10.2 mm. They are being rejected because of their length (10.2mm), not their height (0.5mm).

The material in question is WSF.

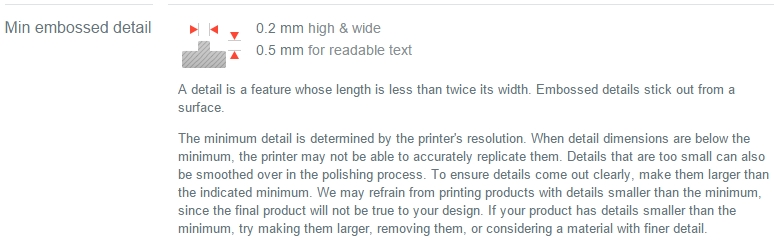

According to these guidelines they qualify as surface detail.

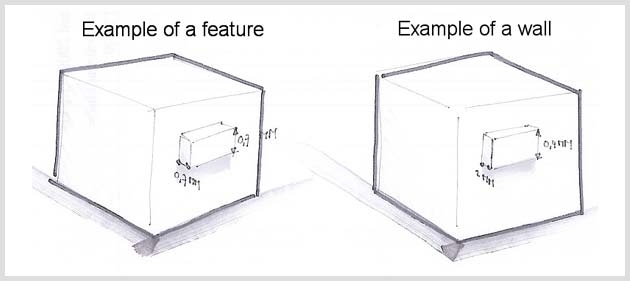

During my 'discussion' with the team I was directed to this tutorial.

https://www.shapeways.com/tutorials/thin_walls_tutorial

All well and good, apart from this diagram, which is a mess.

There is even a note above it admitting that the dimensions on the left are wrong. The dimensions on the right are blurred and therefore useless. If this is being used as the basis for judging our models then it is no wonder they are being rejected. Can someone at Shapeways please sort this mess out and give us some proper guidelines that can't be interpreted in several different ways.

Rant over, thank you and goodnight.

Neil.

edit : a key problem here could be the use of the terms 'height' and 'length'. It's not clear how they should be applied.