This was originally posted in the elasto contest thread, but now that I've actually gotten the prototypes I'm posting it here for any advice/thoughts others may have about this project.

I recently got a

Fitbit Flex activity tracker, but I wasn't fond of wearing the bracelet that it came with, and decided I'd rather attach it to my watchband. I developed this "Fitbit Backpack" for that purpose. This is my first ever 3D printed object, and I'm pretty happy with how it turned out, though the prototype has revealed some problems with the design and also apparently with my modeling ability (using SketchUp)

Here's the backpack next to the fitbit module. As you can see on the left side there was some sort of problem with the model, and it wasn't printed solid.:

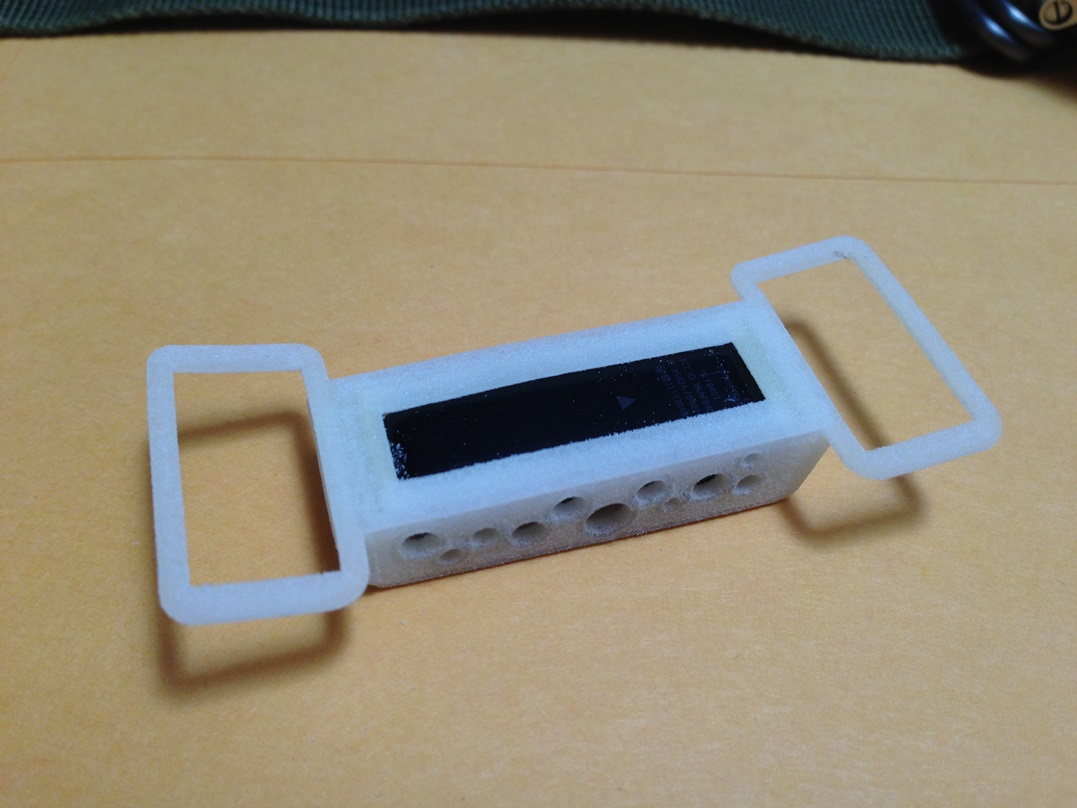

And here's the underside of the backpack, with the fitbit inside. As you can see in the above pic, I made the ring openings too big, so those will get reduced by about half:

And here's the backpack attached to the watchband:

The design works pretty well, though it does add some bulk to the fitbit. I might try reducing the thickness of the walls a bit, as I was a little over the spec'd minimum. The rings at the end, however, are too thin - they break. The elasto material does bend, but it can also develop cracks if it is bent at an angle especially when it is thin. The fitbit fits well inside, though I made the opening a bit too small - need to expand that so I can get it in and out a little easier. There's also some extra room at the top of the unit, so I can probably trim that material a bit and save myself 20 cents.

One other problem I had is that the ring one end does not seem to have been attached well. I think this is the result of creating the rings as seperate models, and then just latching them on to the body of the backpack. I don't know how best to correct this and make the whole thing "one piece" instead of three pieces connected together. Any advice on this?