Hi,

This is my third (and last) post in this section about the objects I received on Friday. There is more to show, but I will probably post about the other objects later, in other sections (problems of design or problems of printing).

I really like interlocked shapes, and I guess 3D printing is one of the best way to actually create them.

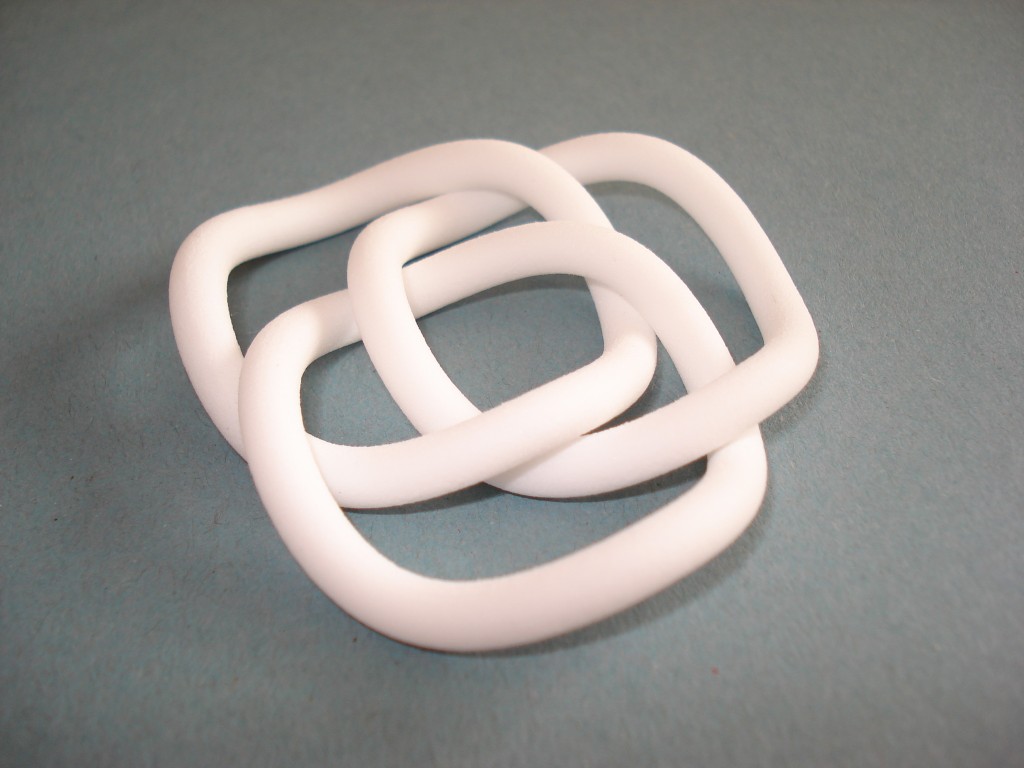

So to begin, here are two Brunnian (or Borromean) links.

First the famous Brunnian rings or

Brunian circles (seen in the coat of arms of the Borromeo family).

Such an interlocking cannot be obtained with standard rings, so I cheated a little bit by giving them a kind of ondulation. All the 3 rings have the same shape and have a nice symmetry (I put the ondulation even where not necessary to keep this symmetry).

The property of all brunnian links is that that even though the 3 links are interlocked, no two of them are actually linked: as a consequence, if you remove (break) just one of them then the two other ones will fall apart.

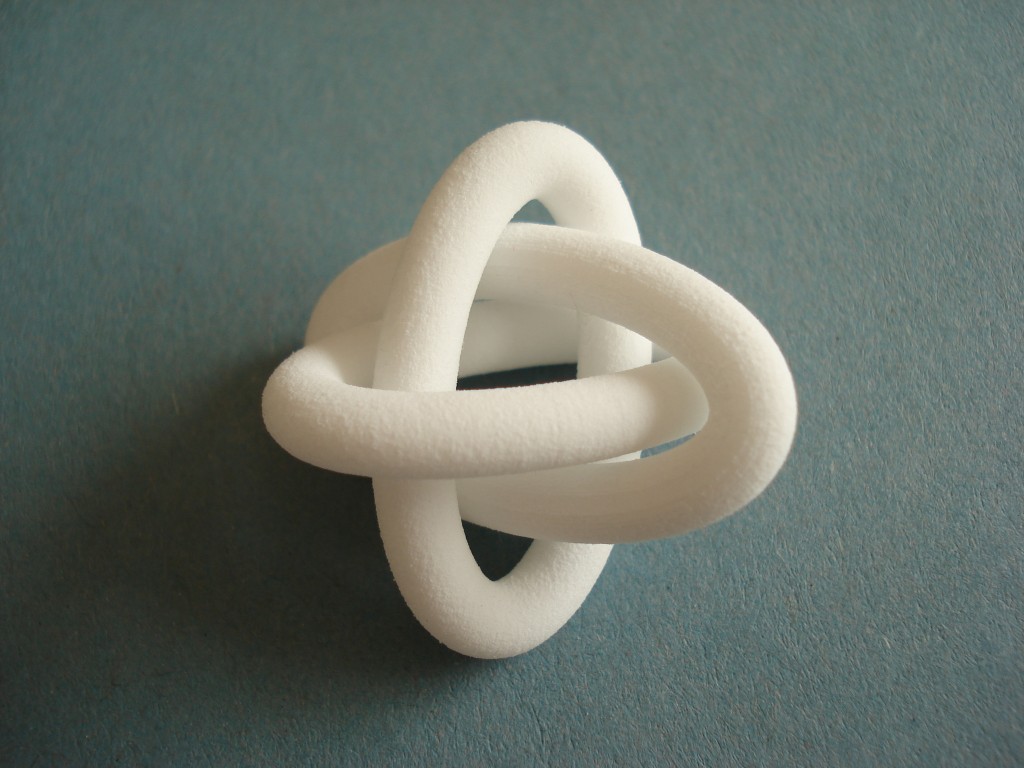

The

Brunian links with each link having an ellipse shape have the same topology as the previous one but don't required any trick.

It is an interesting object to play with.

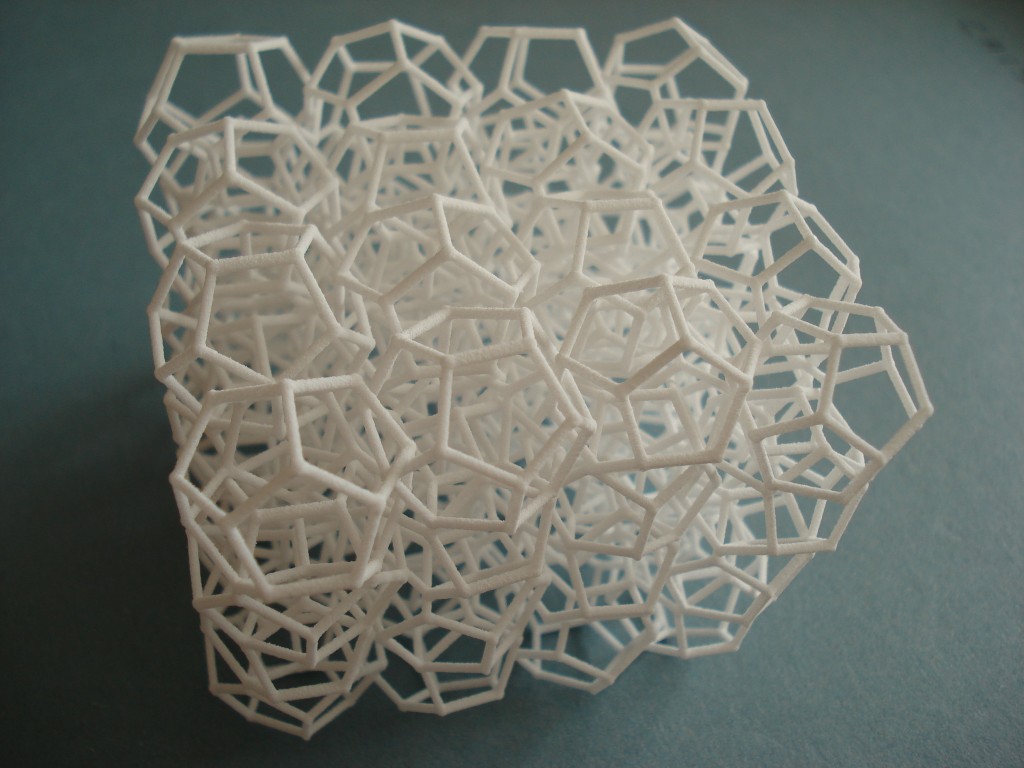

And last but not least, I am really happy to have received the

Dod'net: it is a network of interlocked dodecahedra.

The printing is just FANTASTIC: there is no defect. It is just perfect.

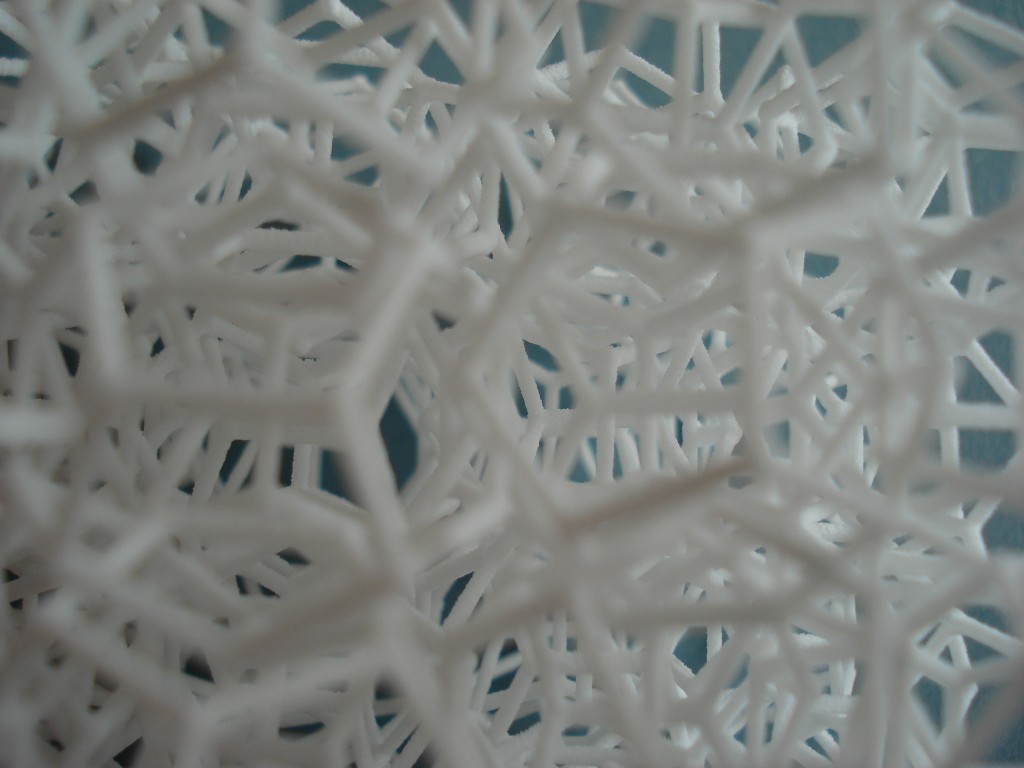

Here are some details.

Of course it is probably very fragile (I did not try to stress it), but I am amazed that such a structure could be printed and arrived with no damages!

Congratulation to all those who manipulated it without breaking it (including myself

)!