Hello,

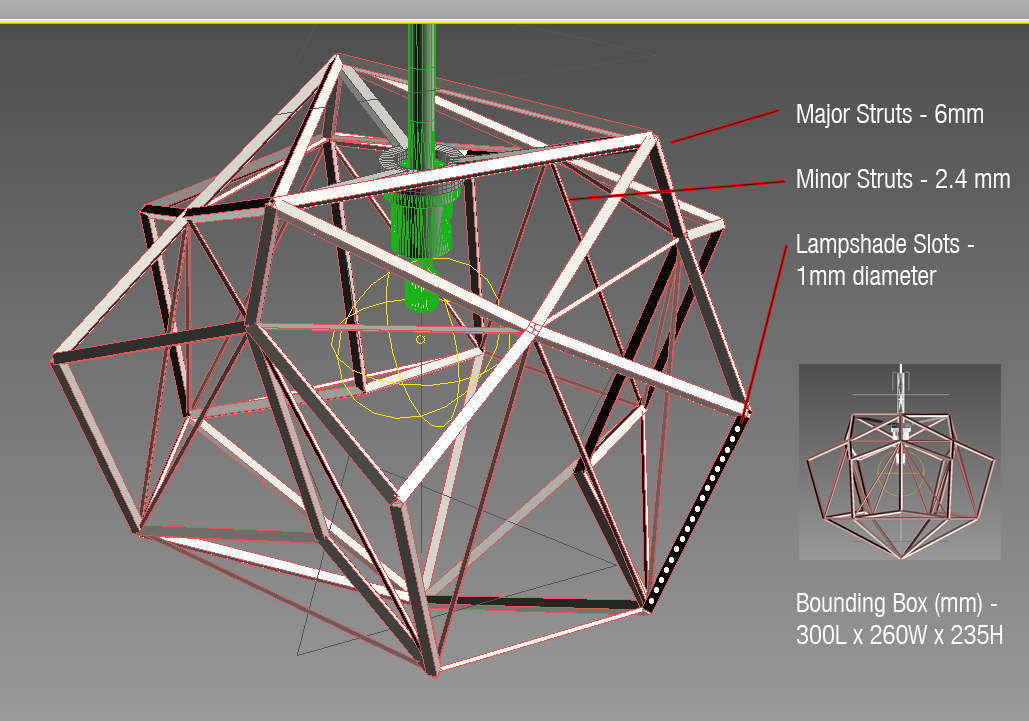

I decided to get my feet wet with 3d printing from an off-hand conversation the other night with my roommate. So I just started designing a pendant lamp that i'm looking to print in plastic. I've attached some renderings I've done of the preliminary design, as well as a wireframe model with some basic info on the design.

Note: The model is a 3d sketch at best, I realize the mesh needs refining and resolving before the print.

Basically, I want to print a lattice type structure for the lamp, that will include a series of slots in some selected struts to pass yarn through as the lampshade. So I have a number of questions regarding the feasibility of the print and material selection.

- How durable is the plastic? I'm using lightweight yarn so I don't imagine that being too much stress on the material, not to mention the amount of struts in the entire lattice. Does this design look stable?

- I'm trying to decide whether or not I should print the object as one piece or design it as a joint system that I can glue together. Part of this decision lies in the material selection (I'm debating matte vs polished white) The Matte white looks like it is a pretty rough finish, but can allow me to print the object entirely in one piece. Is it possible to polish/sand the matte white plastic after receiving it?

- Would a design such as this warp and deform terribly during the print?

I can't think of other questions at the moment, but I'm sure they will pop up. Thanks for any help in advance!