You didn't set the model to public so that we could see it.

====

One answer to your request is to lookup the "Ball Pivoting Algorithm", one paper on it is here:

http://www.research.ibm.com/vistechnology/pdf/bpa_tvcg.pdf

The other answer: (non-programmers

stop reading here!)

You can't do the entire surface in a single step. You must treat each triangle separately. For every triangle you have currently, it must become a solid with "thickness", rather than a single surface. Then, add all the solids together using Constructive Solid Geometry (CSG). May I suggest you spend some time with

Openscad? It has CSG algorithims it uses, and the source is freely available.

Steps:

For every triangle:

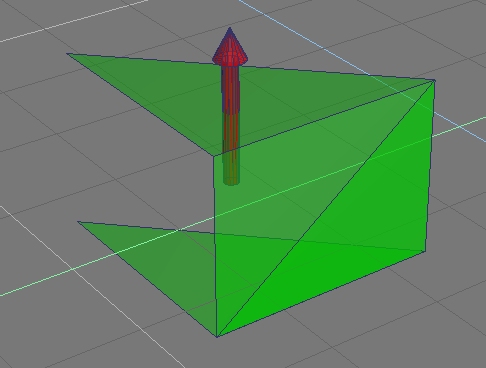

-Compute the surface normal to your triangle.

-Add a new triangle A,B,C some delta distance away from the original (half of the desired thickness) along the positive surface normal.

-Add a new triangle with the opposite "winding order" (C,B,A) offset in the negative surface normal direction. We'll call this triangle D,E,F

---This gives you the two "plates" (top and bottom) for the new solid.

-Now, work around the edges of the plates, filling in the "side" triangles: (A,B,D) and (D,B,E) and so forth.

-Each final solid will be made up of 8 triangles instead of just one.

Once all the new solids have been generated, use CSG-union to combine all them into a single solid.

Hint: if you produce all the separate solids into a single STL, then Netfabb-Cloud has a free service to union them all together.