Instructions for the DCC conversion.

For the loco it should be the same as per DC. The wiring will look a bit different, but if you are using the new hollow domes you shouldn't need to touch that.

The tender needs less work than before. Remove the body by unclipping it. Also removed the coupler lifting bar at the rear. Unplug the lead from the loco. Cut off the footsteps.

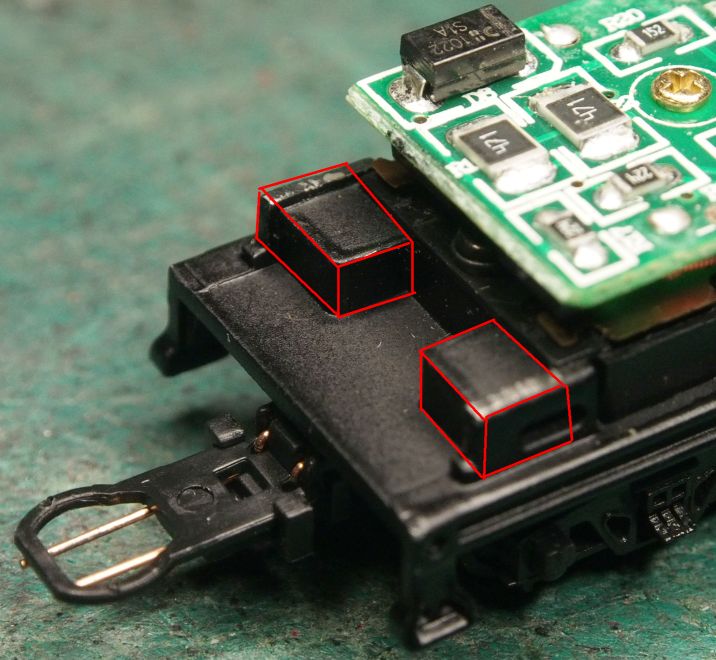

Now for the only major work, two lumps of metal at the front of the chassis need to be removed (marked in red).

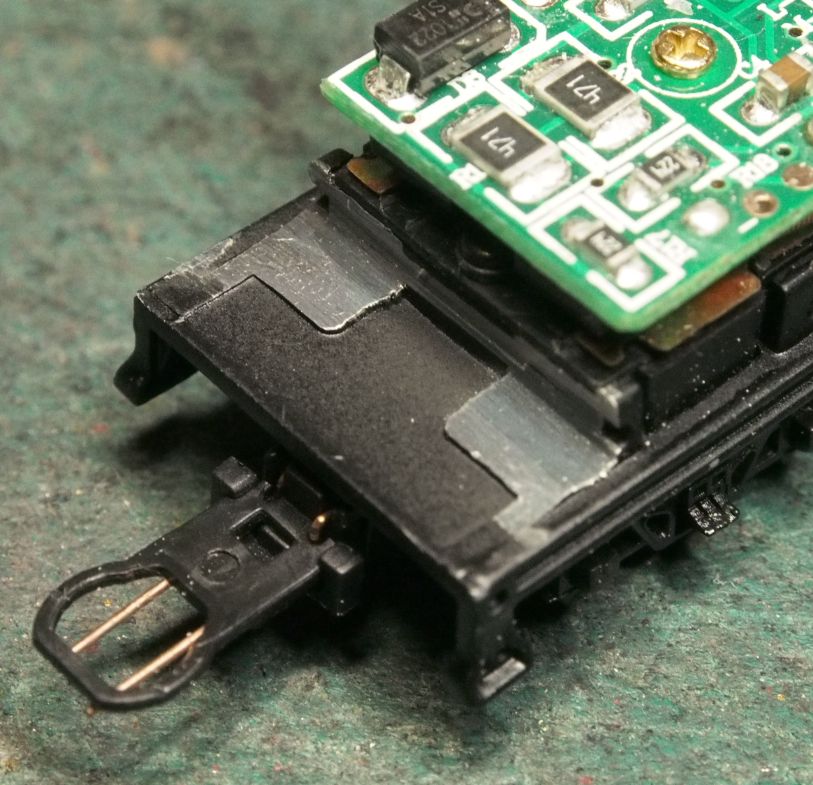

You are aiming for this.

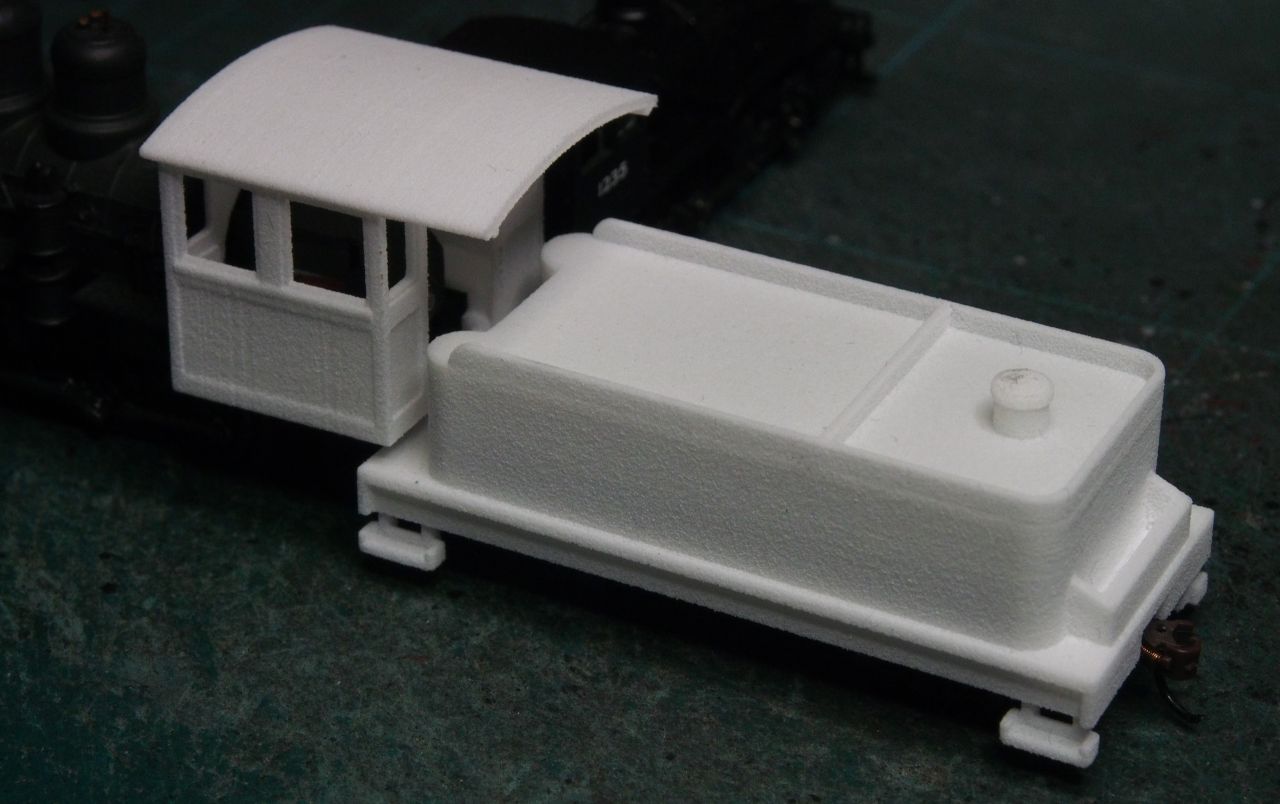

The new body should now fit onto the chassis. The lead from the loco passes through the hole at the front of the body.

You can retain the original coupler, or remove it and fit a Microtrains 1015 as before.

The gap between loco and tender is less than before, but it should go round most curves.

Note - I have designed two tenders for this conversion.

The Low one is the same height as the DC version. This has a hole in the coal space to allow room for the plug. This can be hidden with a coal load.

The High one is 2mm taller than the DC one. The plug is completely hidden, but the tender top is smooth with no coal space. This can also be hidden with a coal load.